Underwater concrete pouring method in underwater bridge construction

A technology for underwater concrete and bridge construction, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of large contact space between concrete and water body in the conduit, concrete is easy to be washed by water, and the length of the conduit cannot be changed at will.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and cases, and these cases are only used to illustrate the present invention and not limit its scope.

[0020] The underwater concrete pouring method in the underwater bridge construction comprises the following steps:

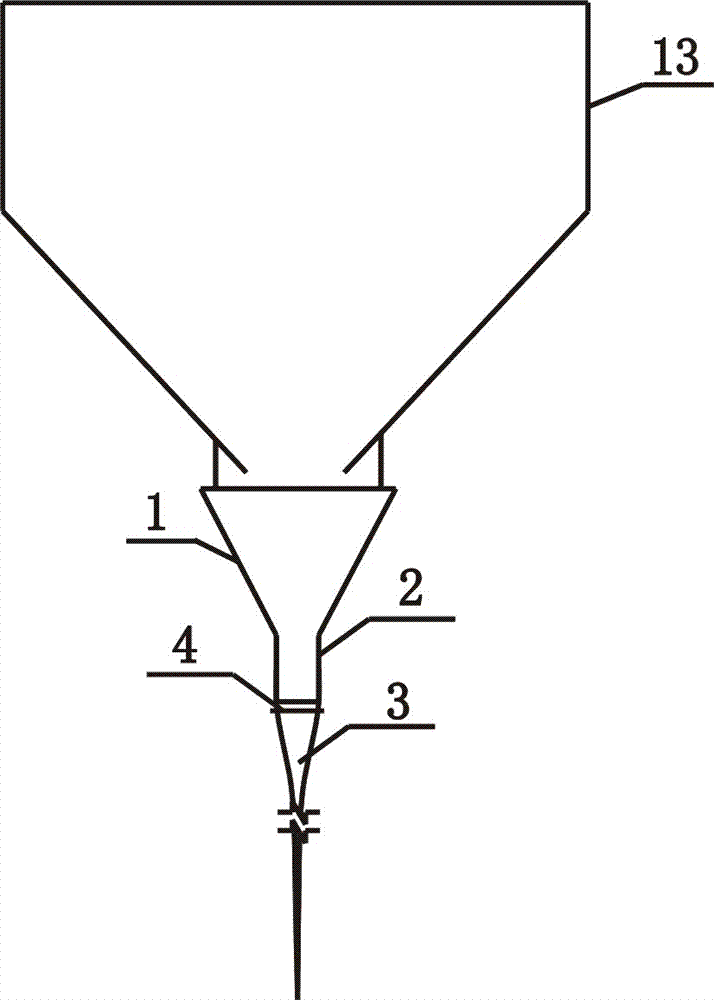

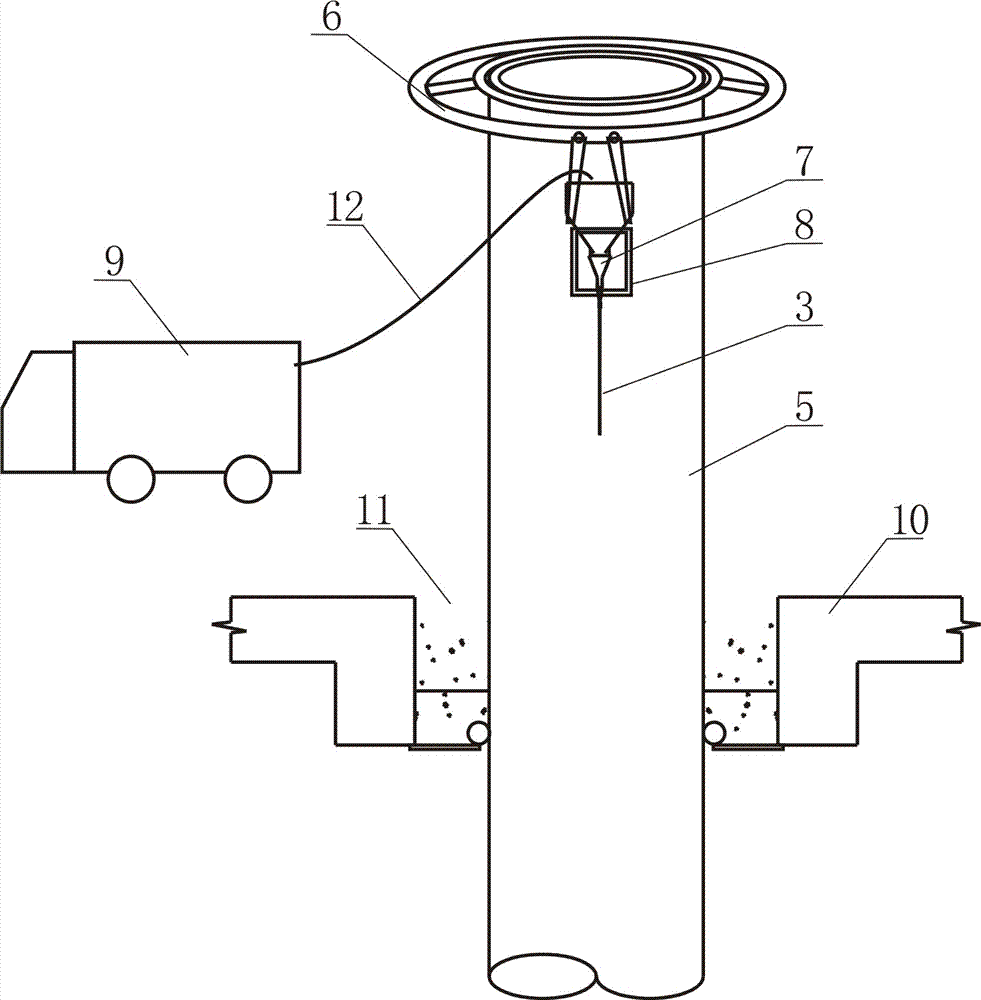

[0021] A. Sink production: Sink 7 is composed of a horn-shaped flared part 1 and a round tubular leak nozzle part 2. A horn-shaped flared part 1 with an upper opening diameter of about 30 cm is rolled with a 4 mm thick steel plate, and a round tubular leak nozzle The diameter of part 2 is about 15cm. According to the actual distance from the top of the cap steel casing to the bottom of the steel hanging box floor, cut the corresponding length of rubber hose 3 with an inner diameter of about 16cm. Connect and fasten with iron wire 4. The lower end of the rubber hose is free and can swing freely. When no concrete passes through, the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com