Pressure medium supplying device for hydrostatic driving device

A pressure medium and supply device technology, applied in the direction of fluid pressure actuation device, transmission device control, accumulator device, etc., can solve the problems of descending function and negative impact, so as to improve efficiency, reduce cost, and avoid empty space hole effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

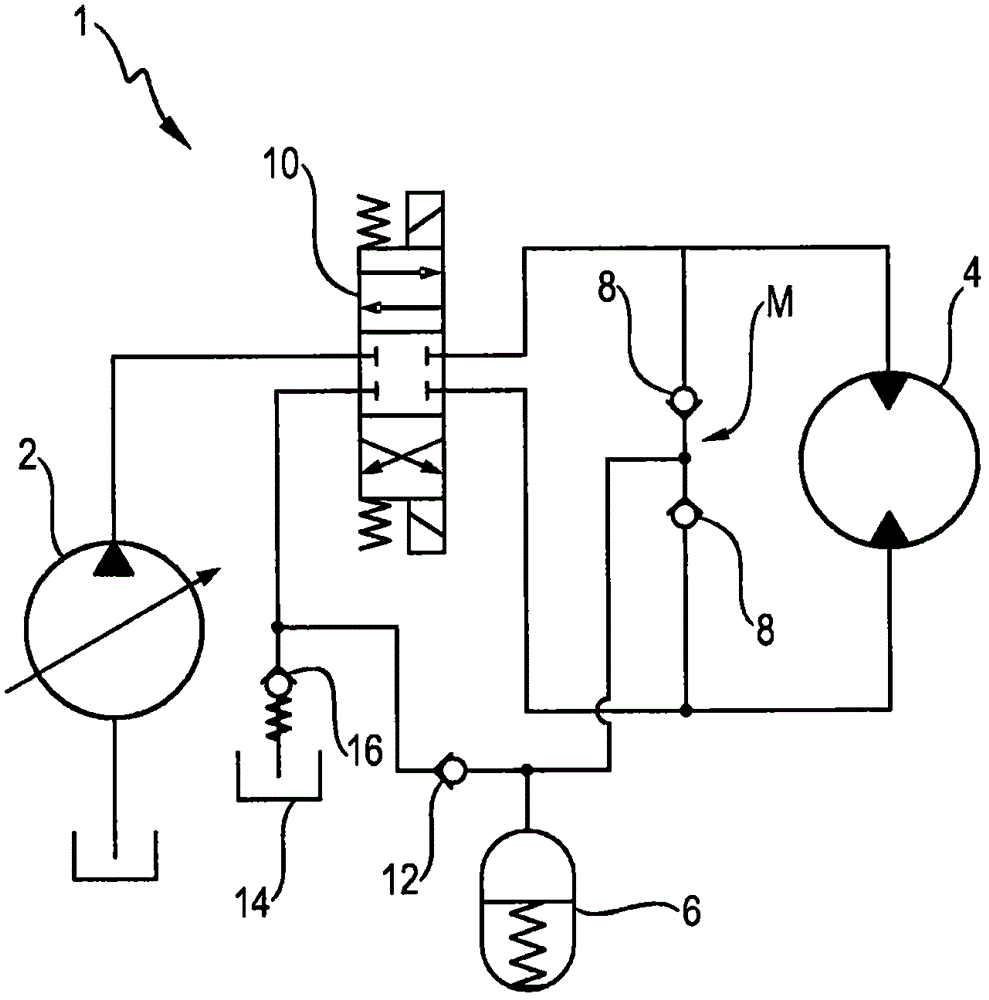

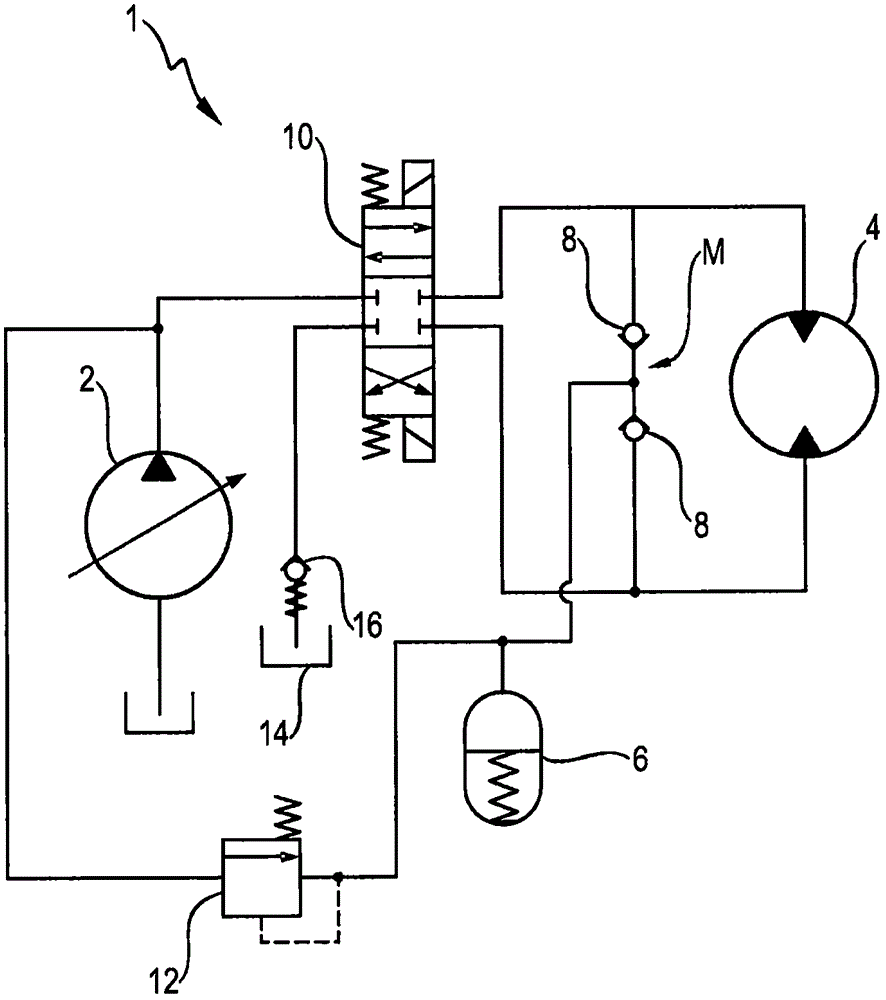

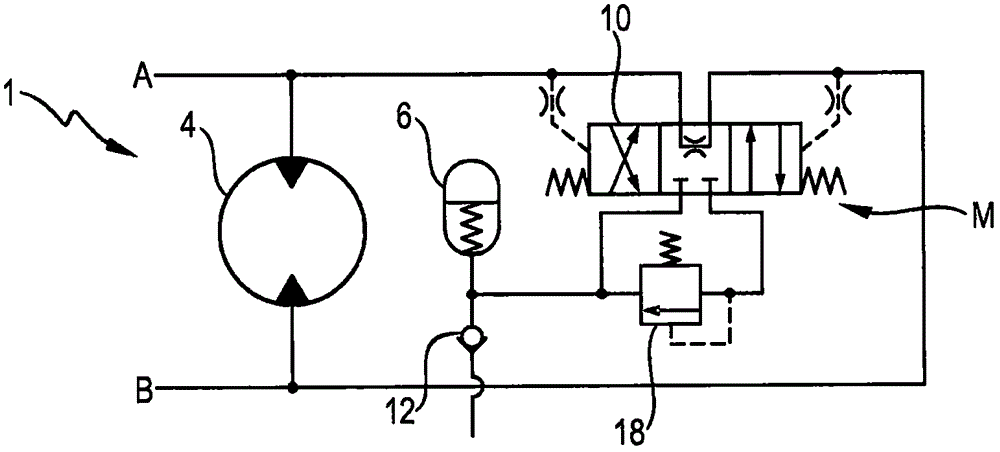

[0048] According to the pressure medium supply device 1 for a hydrostatic drive according to the first embodiment of the invention, in figure 1 The circuit diagram shown in contains a hydraulic pump 2 adjustable in its displacement volume, which is fluidically connected to a hydraulic motor 4 in an open circuit and drives it.

[0049]Via the supply connection M, the hydraulic motor 4 can be supplied with pressure medium from the pressure accumulator 6 in order to avoid cavitation. The supply connection M is connected in parallel to the hydraulic motor 4 and has two shut-off valves 8 , which each release the pressure medium flow from the pressure accumulator 6 to the hydraulic motor 4 . The two shut-off valves 8 and the supply connection M are integrated in the hydraulic motor 4 or in its housing.

[0050] A multi-way slide valve 10 designed here as a 4 / 3 bypass valve is provided for controlling the drive direction of the hydraulic motor 4 . One switch-on position of the mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com