Repair method of high energy igniter oil gun

A repair method and high-energy point technology, applied in the direction of welding equipment, manufacturing tools, welding/cutting media/materials, etc., can solve the problems of easy burning through the pipe wall, scalding the lining insulation secondary sleeve hose, etc., to prevent burning The effect of penetrating the pipe wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further described below.

[0035] The method for repairing a high-energy igniter oil gun disclosed by the present invention comprises the following steps:

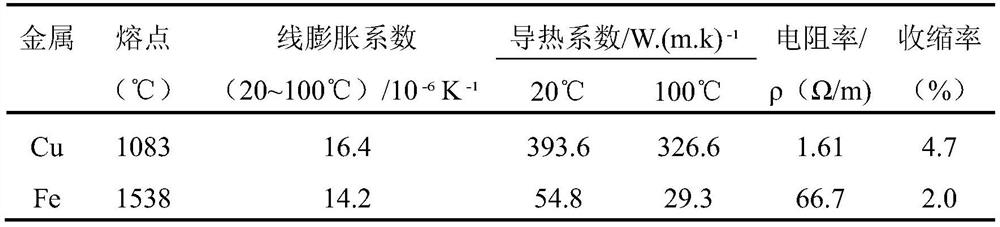

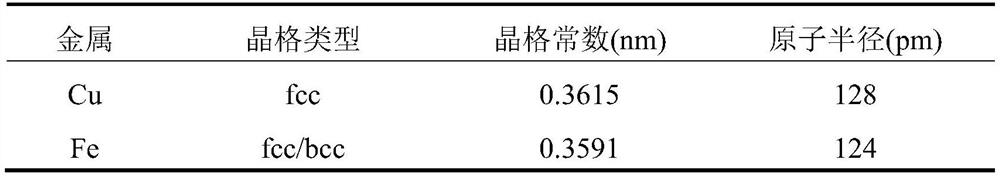

[0036] Material selection: select the welding wire that matches the welding base material of the high-energy igniter oil gun;

[0037] Cleaning and assembly: clean the copper end of the high-energy igniter oil gun and the welding part of the steel joint, and assemble the copper end and the steel joint;

[0038] Welding: Tungsten argon arc welding is used to weld the copper end and the steel joint, the diameter of the welding wire is 2.2-2.6mm, the welding speed is 40-60mm / min, the welding current is 50-80A, the arc voltage is 12-15V, and the argon gas flow rate is 10 ~15L / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com