Titanium alloy laser additive repair and surface nitriding composite treatment process

A laser additive and composite processing technology, applied in metal material coating technology, additive processing, metal processing equipment, etc., can solve problems such as high cost, pores and cracks, and processing, and achieve the effect of avoiding metallurgical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take TC4 (α+β duplex) alloy as an example.

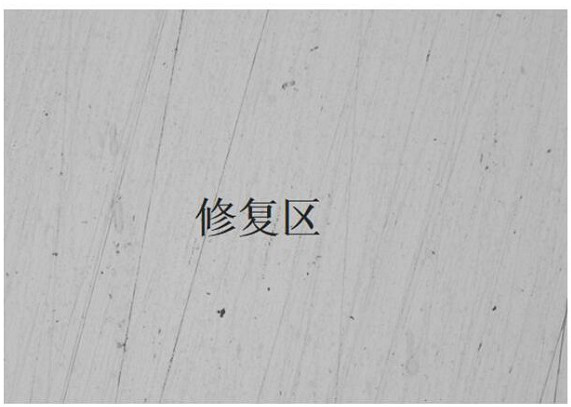

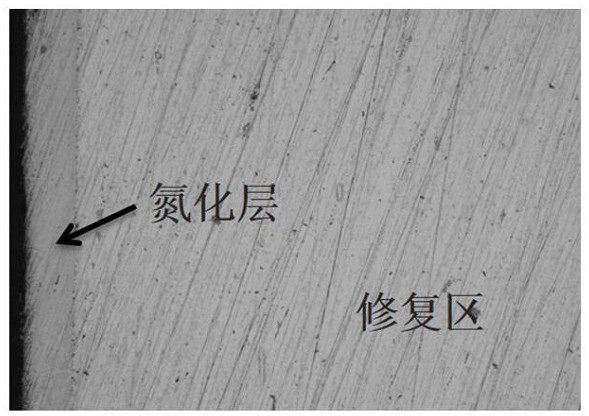

[0021] Step 1: Perform pretreatment on the surface of TC4 alloy parts, including machining, cleaning, sandblasting and drying of the area to be repaired; Step 2: Use a thermal imager to monitor the molten pool during the laser additive manufacturing process to obtain the shape of the molten pool appearance and temperature change information, calculate the average value a of the long axis of the molten pool and the average value b of the short axis, and calculate the average cooling rate ξ of the boundary of the molten pool; Step 3: According to 1.5≤a / b≤2.2, and 7.0×10 3 ℃ / s≤ξ≤8.3×10 4 The process parameters are optimized based on the ℃ / s principle to obtain the optimized additive repair process window: the laser power is 1350W, the scanning speed is 13mm / s, the spot diameter is 3.8mm, the powder feeding amount is 26g / min, and the overlapping amount is 50% , the height direction increment Z is 0.3 mm / layer, the repair materia...

Embodiment 2

[0025] Take TB1 (β type) alloy as an example.

[0026] Step 1: Perform pretreatment on the surface of TB1 titanium alloy parts, including machining, cleaning, sandblasting and drying of the area to be repaired; Step 2: Use a thermal imager to monitor the molten pool during the laser additive manufacturing process to obtain the molten pool Shape and temperature change information, calculate the average value a of the long axis of the molten pool and the average value b of the short axis, and calculate the average cooling rate ξ of the molten pool boundary; Step 3: According to 1.5≤a / b≤2.2, and 7.0× 10 3 ℃ / s≤ξ≤8.3×10 4 The ℃ / s principle optimizes the process parameters to obtain the optimized additive repair process window: the laser power is 1450W, the scanning speed is 13mm / s, the spot diameter is 3.5mm, the powder feeding amount is 27g / min, and the overlapping amount is 50% , the height direction increment Z is 0.3 mm / layer, the repair material is a mixed powder of TB1 tita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com