Waterproof combination self-tapping screw

A self-tapping screw and screw technology, which is applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of not taking into account the improvement of the waterproof performance of self-tapping screws, achieve good repeatability, improve tensile strength, and increase stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

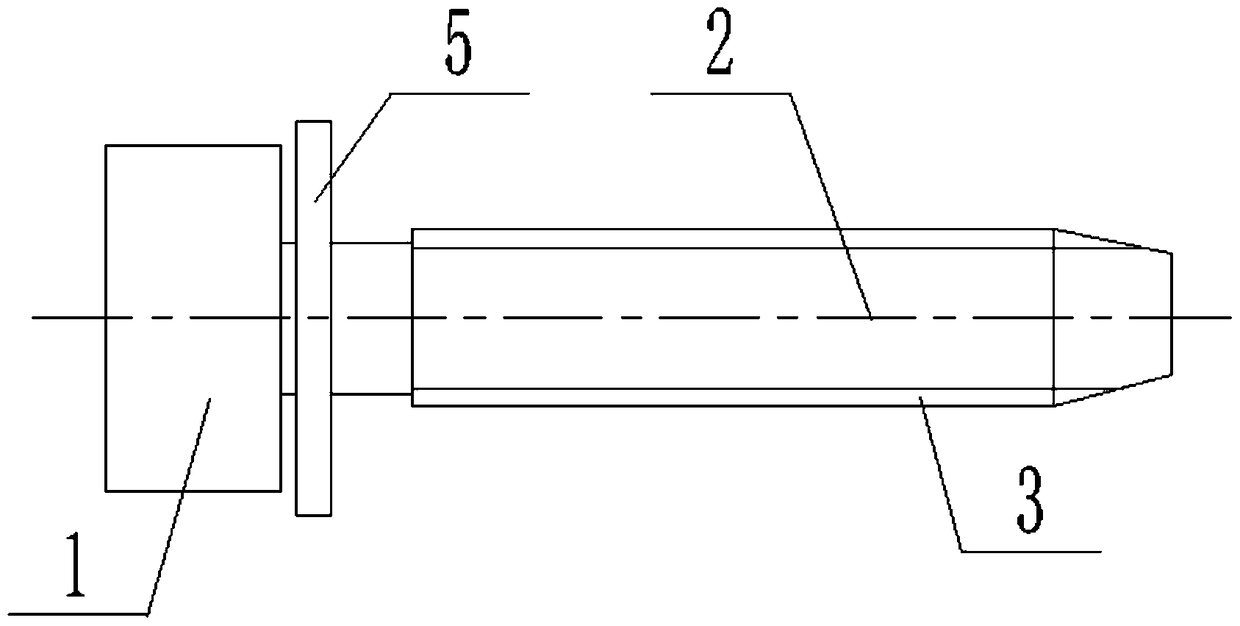

[0038] Please refer to the attached figure 1 with 2 , the waterproof combination self-tapping screw of this embodiment includes:

[0039] screw head 1, located at the head of the self-tapping screw;

[0040] The screw rod 2 is connected with the screw head 1 and is located at the tail of the self-tapping screw;

[0041] The thread 3 is arranged on the circumference of the screw 2;

[0042] Silicone gasket (not shown), arranged on the neck position where the screw head 1 and the screw rod 2 are connected, for waterproofing; and

[0043] The flat gasket 5 is arranged at the neck position where the screw head 1 and the screw rod 2 are connected, and is close to the side of the screw head 1; the screw head 1, the flat gasket 5 and the silicone gasket (not shown) are sequentially connected;

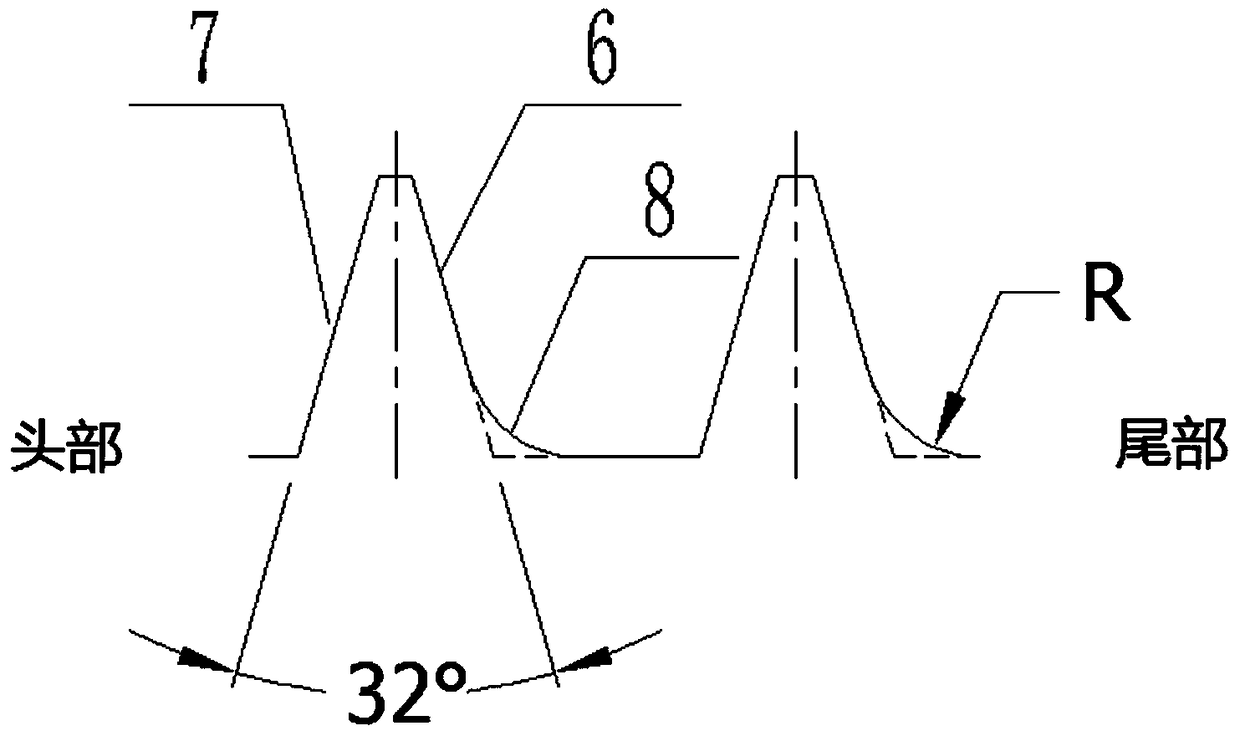

[0044] The thread 3 includes a first contact surface 6 near the tail of the self-tapping screw, and a second contact surface 7 near the head of the self-tapping screw.

[0045] A profile ...

Embodiment 2

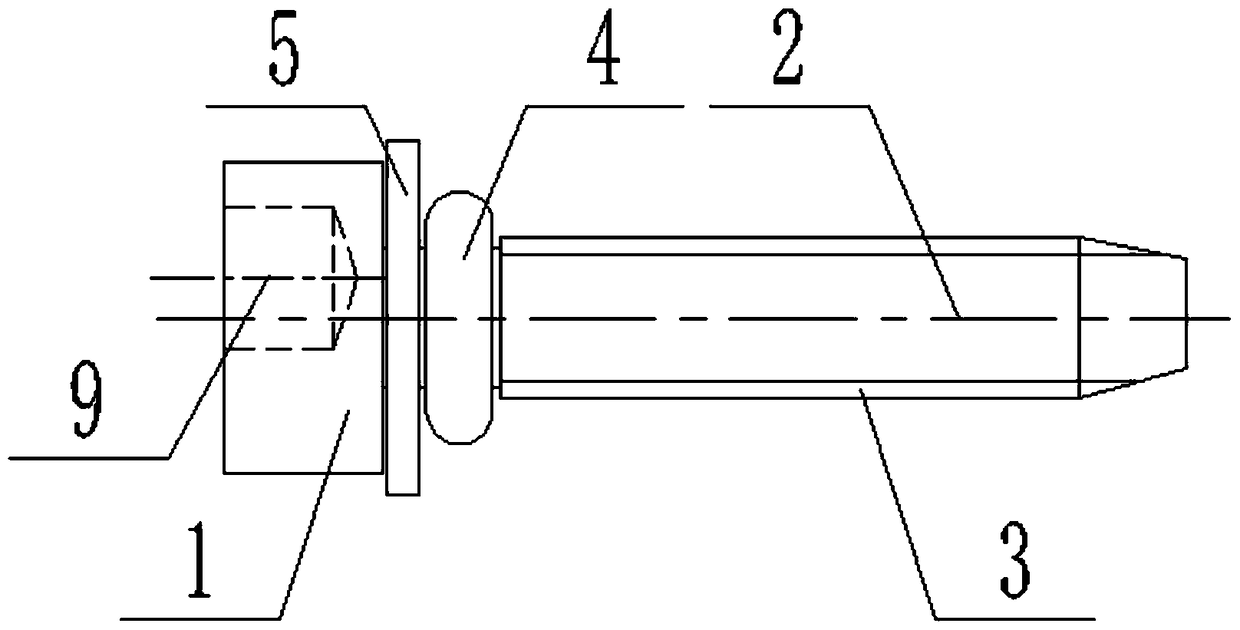

[0055] Please refer to the attached Figures 3 to 5 , the waterproof combination self-tapping screw of this embodiment includes:

[0056] screw head 1, located at the head of the self-tapping screw;

[0057] The screw rod 2 is connected with the screw head 1 and is located at the tail of the self-tapping screw; the tail of the screw rod is tapered to facilitate self-tapping;

[0058] The thread 3 is arranged on the circumference of the screw rod 2;

[0059] Silicone gasket 4 is arranged at the neck position where the screw head 1 and the screw rod 2 are connected, and is used for waterproofing; and

[0060] The flat gasket 5 is arranged at the neck position where the screw head 1 and the screw rod 2 are connected, and is close to the side of the screw head 1; the screw head 1, the flat gasket 5 and the silicone gasket 4 are sequentially connected;

[0061] The screw head 1 is provided with a mounting hole 9, and the axis line of the mounting hole 9 deviates from the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com