Knitted fabric and preparation method thereof

A technology for knitted fabrics and knitted fabrics, applied in the field of knitting dyeing and finishing, which can solve problems such as long process flow, waste of resources, and increased radial tension, achieve consistent chemical additive concentration, facilitate shrinkage control, and reduce radial tension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] In a specific embodiment of the present invention, a kind of preparation method of knitted fabric is provided, and this preparation method may comprise the following steps:

[0019] Squeeze water on the knitted fabric after dyeing or washing, and control the liquid-carrying rate of the fabric surface to not be higher than 100%;

[0020] Carry out foam wet setting treatment on the knitted fabric after water rolling, that is: foam the finishing liquid through a foam generator to obtain a uniform size of finishing liquid foam, and use the foam application equipment to apply the finishing liquid foam to the knitted fabric, so that the knitted fabric A certain amount of finishing liquid is applied to the surface of the cloth, and then the knitted fabric is obtained by tenter drying.

[0021] The preparation method of the knitted fabric in this specific embodiment is to carry out foam finishing on the wet cloth after the open-width water rolling, and apply the finishing liqui...

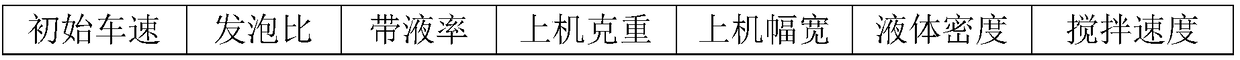

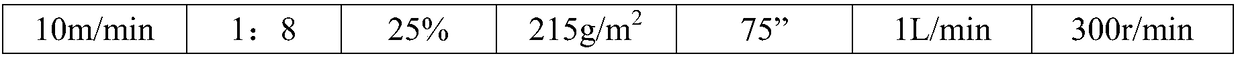

Embodiment 1

[0036] This embodiment provides a production method of a 32S / 1 single-pearl elastic knitted fabric with a grammage of 215g / m 2 , and its technological process is: knitting→washing→open width rolling→wet setting→finished product. The production method comprises the following steps:

[0037] Knitting: use circular weft machine to weave yarn to obtain knitted fabric;

[0038]Washing water: the above-mentioned knitted fabric is washed with conventional processes, enzyme washed, and softened in the tank; among them, the washing process is: the working fluid contains 0.15g / L penetrant JFC (Dongguan Jiahong Organic Silicon Technology Co., Ltd.) , 0.5g / L soaping agent DM-1593 (Guangdong Demei Fine Chemical Co., Ltd.), the treatment temperature is 70°C, and the time is 30min; enzyme washing process: configure working solution (pH value is 5-7), liquor ratio 1:15, treated at 55°C for 60 minutes, and treated in a water bath at 80°C for 10 minutes to kill enzymes; the composition of the...

Embodiment 2

[0052] This embodiment provides a production method of a 30S / 1 pure cotton single-pipe solid-color knitted fabric with a grammage of 175g / m 2 , Color: white, its technological process is: knitting→dyeing→open width rolling→wet setting→finished product. The production method comprises the following steps:

[0053] Knitting: use circular weft machine to weave yarn to obtain knitted fabric;

[0054] Dyeing: the above-mentioned knitted fabric is scoured, enzyme-washed and bleached by conventional techniques; wherein, scouring is carried out with NaOH solution containing 1.5g / L scouring agent CLARITE ONE (Huntsman Chemical Trading Co., Ltd.), 5g / L and 18.5 g / L of H 2 o 2 solution, the treatment temperature is 95°C, and the time is 50 minutes; enzyme washing process: prepare working solution (pH value 5-7), bath ratio is 1:25, treat at 55°C for 50 minutes, and treat in 80°C water bath for 10 minutes to kill enzymes; The composition of the enzyme washing working solution is shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com