Tapping screw for engineering plastics

A technology of self-tapping screws and engineering plastics, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problem of insufficient fluidity, stability, tensile and torsion resistance of self-tapping screws, affecting the installation performance of self-tapping screws, Intensity and life, root width can not be further increased to achieve the effect of improving safety and fatigue resistance, small radial tension, and optimizing contact pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

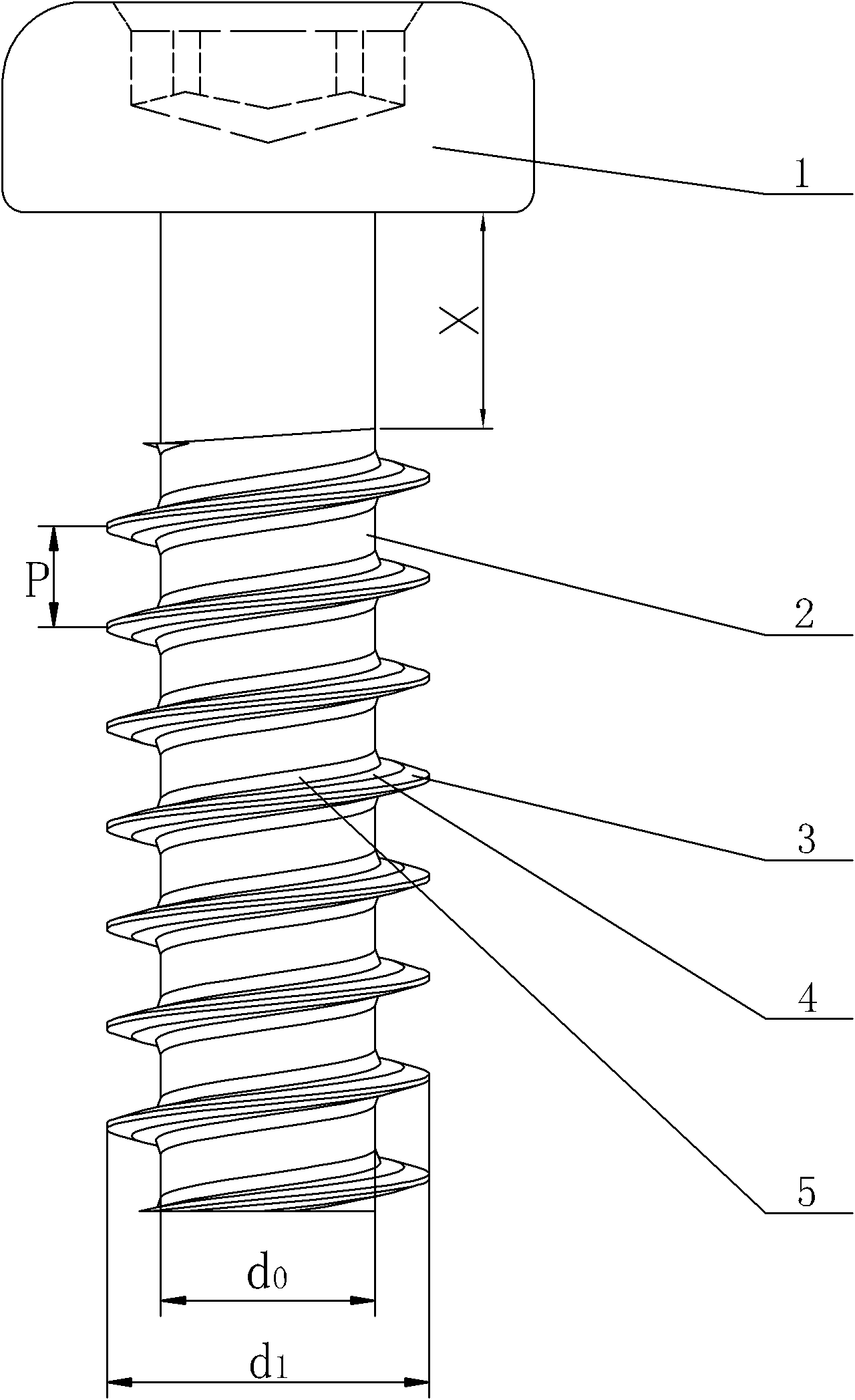

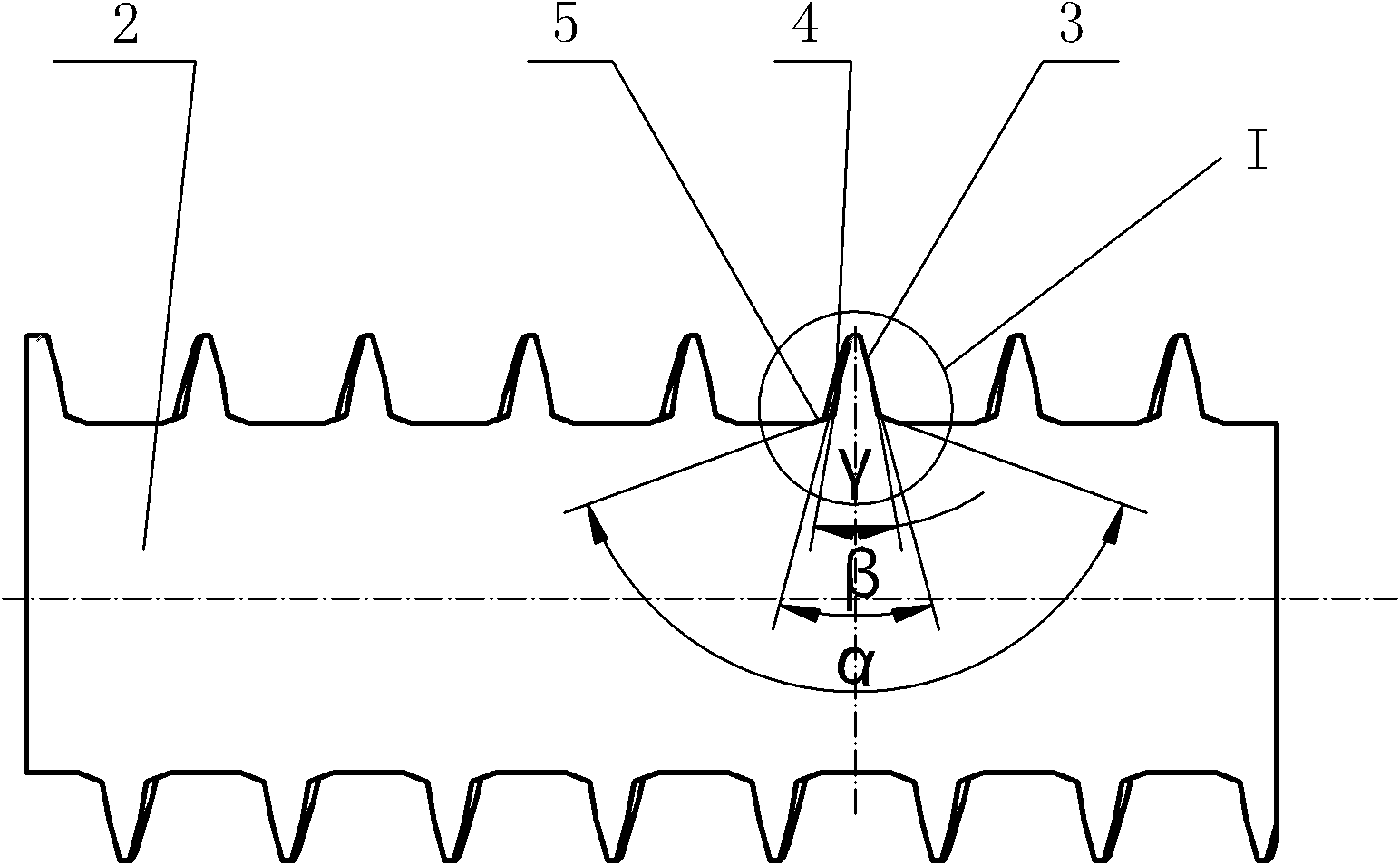

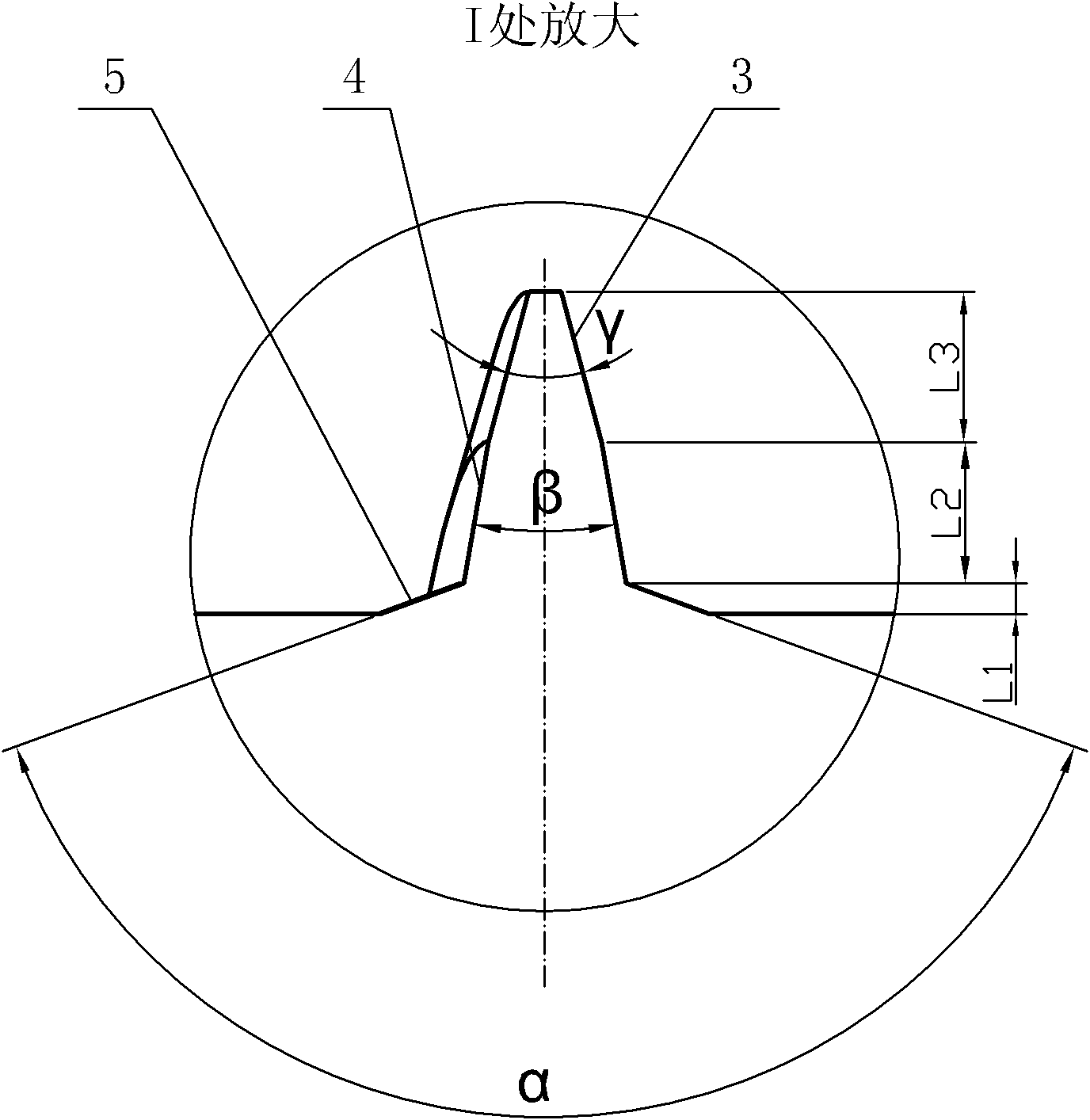

[0011] See Figure 1~3 As shown, the self-tapping screw for engineering plastics of the present invention includes a screw head 1 and a screw rod 2, the screw rod 2 is provided with a helical thread, and the thread has an outer diameter d1, an inner diameter d 0 And the pitch P, the total length of the thread profile is (d1-d 0 ) / 2, the thread crest is the thread outer diameter d1, and the thread bottom is the thread inner diameter d 0 , the length of the head polished rod is X, from the bottom of the screw tooth to the top of the screw tooth, the outer contour of the thread profile section of the present invention is arranged symmetrically along the center and connected in sequence with the inner bevel 5, the middle bevel 4, the outer bevel 3 and the The outer inclined surface 3 is connected to the top surface of the tooth, so that the side part of the outer contour of the thread profile section forms a three-section structure, and correspondingly forms a multi-angle tooth a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com