Cycloid steel ball planetary reducer gap elimination mechanism

A technology of planetary reducer and cycloidal steel ball, which is applied in the direction of mechanical equipment, transmission parts, belt/chain/gear, etc. It can solve the problems of large frictional resistance of planetary disk, decreased transmission performance, and inability to realize axial force output, etc. , to achieve the effects of small axial movement resistance, elimination of backlash and small frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

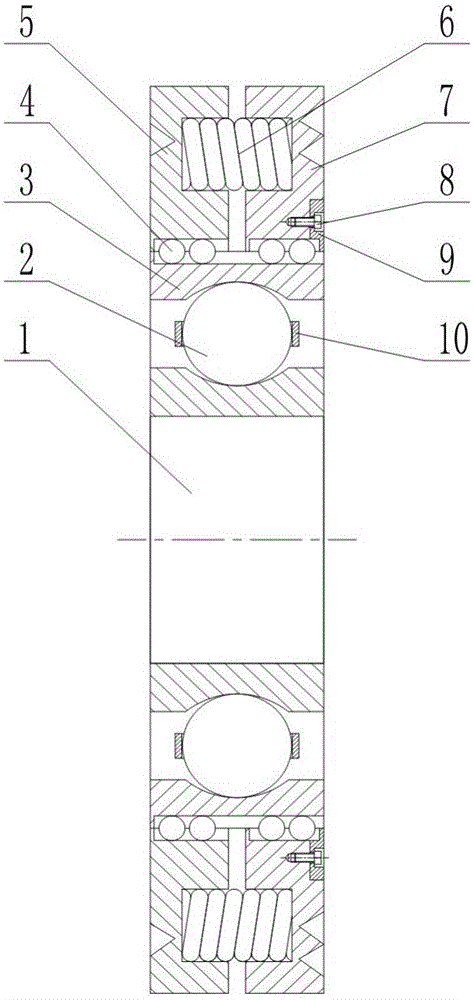

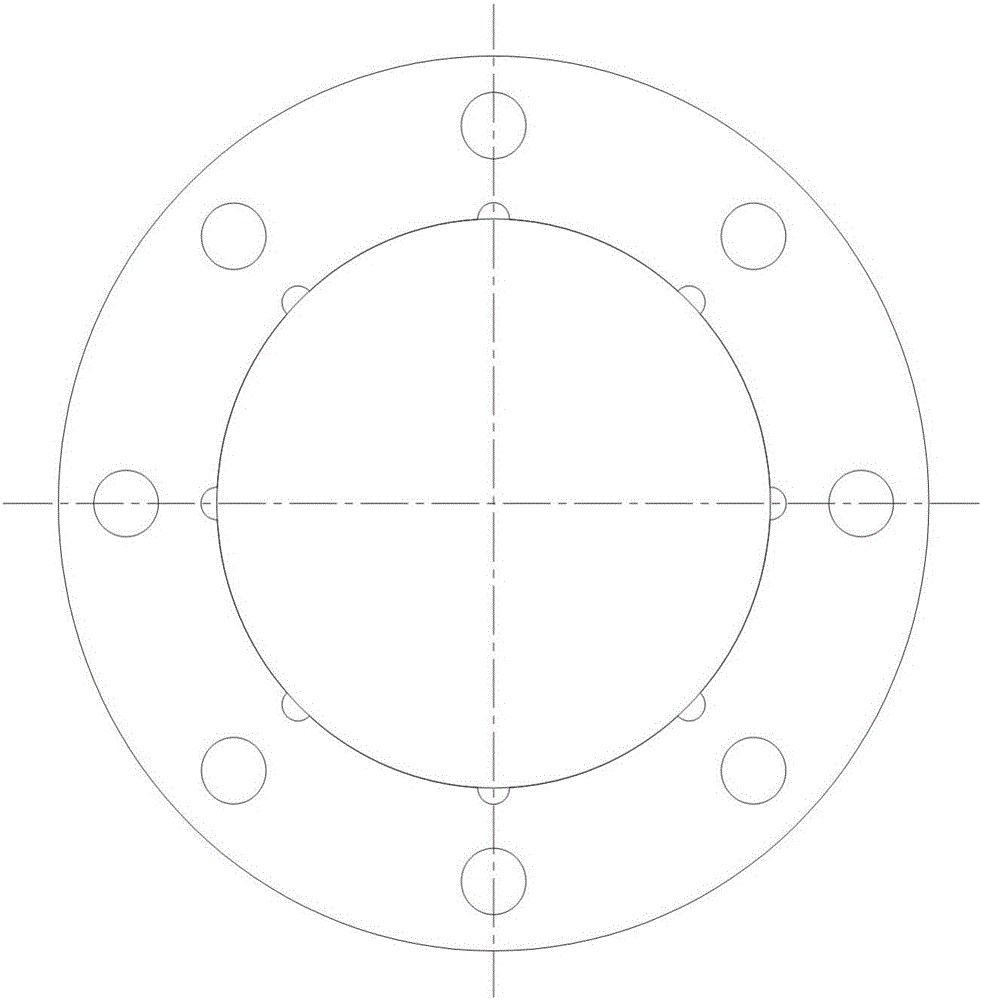

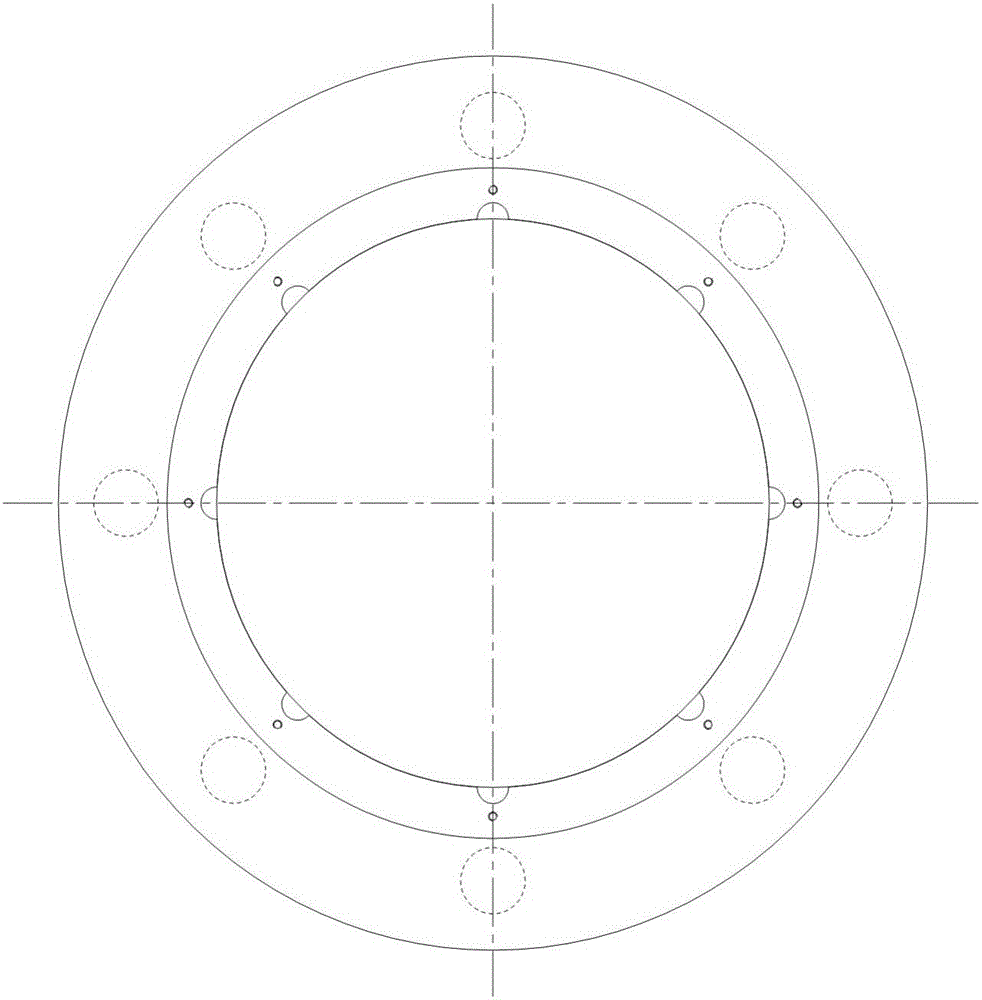

[0012] exist figure 1 , figure 2 and image 3 In the schematic diagram of the present invention shown, the outer part of the inner ring 1 is provided with a cage 10, the cross section of the cage is circular, and a number of ball pockets are provided on the cage, and the steel ball A2 is placed in the cage The inside of the ball pocket. The outer ring 3 is sleeved on the outside of the cage. Eight rolling grooves are arranged on the outer side of the outer ring, and baffle plates are arranged at one end of the rolling grooves on the outer side of the outer ring. Both the inner rings of the movable disc A5 and the inner rings of the movable disc B7 are provided with 8 rolling grooves, and the inner rings of the movable disc A and the movable disc B are provided with baffles at one end of the rolling grooves. The rolling grooves on the outer side of the outer ring correspond to the rolling grooves on the inner rings of the movable disc A and the movable disc B one by one, f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap