A Measuring Method of Curvature Radius of Tapered Roller

A technology of tapered roller and radius of curvature, which is applied in the field of automatic detection of bearing rollers, can solve the problems of high measurement accuracy, large measurement error, and difficult to achieve, and achieve the effect of improving measurement accuracy, avoiding manual errors and improving factory performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

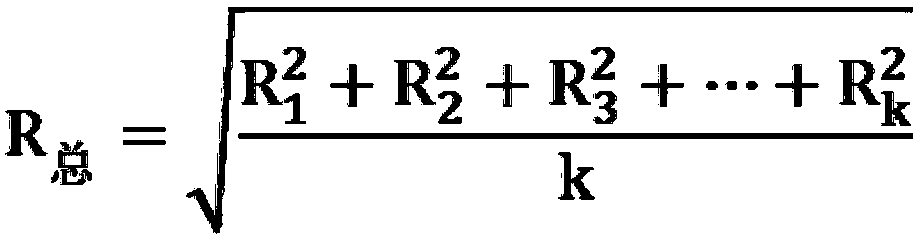

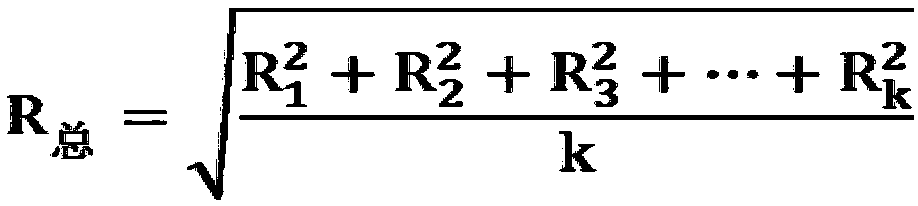

[0030] The invention is a method for measuring the radius of curvature of a tapered roller. The invention uses a laser displacement sensor to measure the radius of curvature of two sections of different circular arcs at the same height of the tapered roller, and then uses the least square method to fit the radius of curvature at the height. , Repeat the same process to measure the radius of curvature at other heights, so as to calculate the total radius of curvature of the tapered roller, and judge whether the total radius of curvature meets the design requirements.

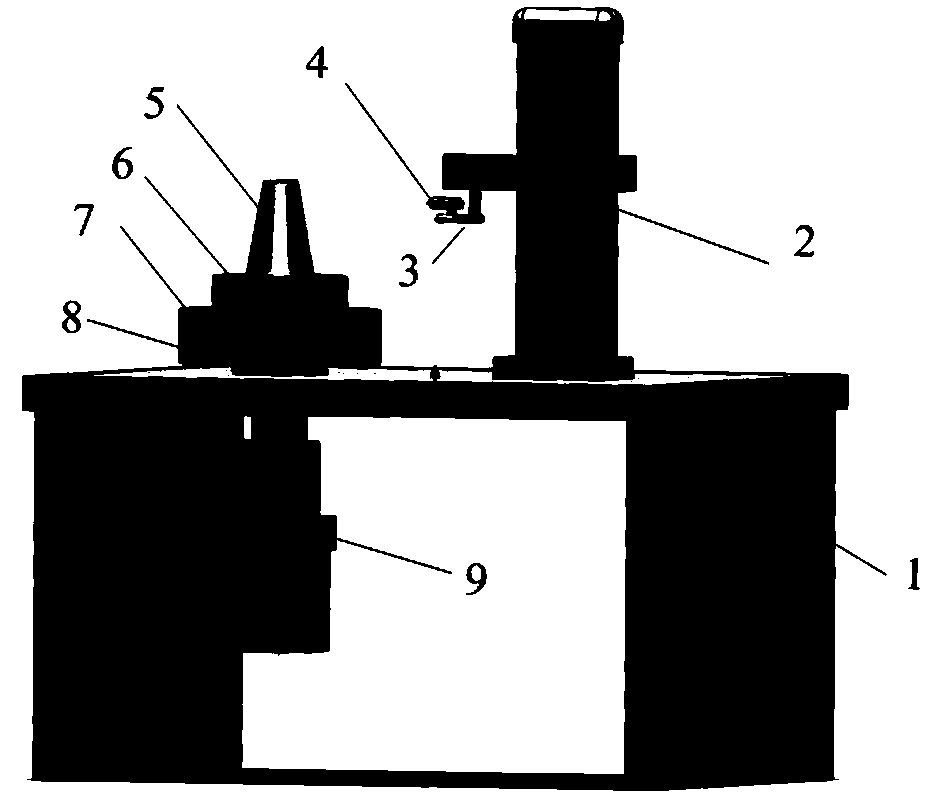

[0031] combine figure 1 , The method of the present invention uses a set of measuring devices, the measuring device includes a base 1, a two-dimensional mobile movable frame 2, a bracket 3, a laser displacement sensor 4, a clamping sleeve 6, an air bearing turntable 7, and an air bearing 8 And the servo motor 9, the rotation angle and the rotation speed v of the servo motor 9 1 and v 2 are controlled by compute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com