A lens anti-shake device with self-locking structure

A self-locking structure and lens technology, applied in projection devices, printing devices, installations, etc., can solve the problems of increasing the load of the anti-shake structure, shortening the service life of the anti-shake mechanism, etc. Small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

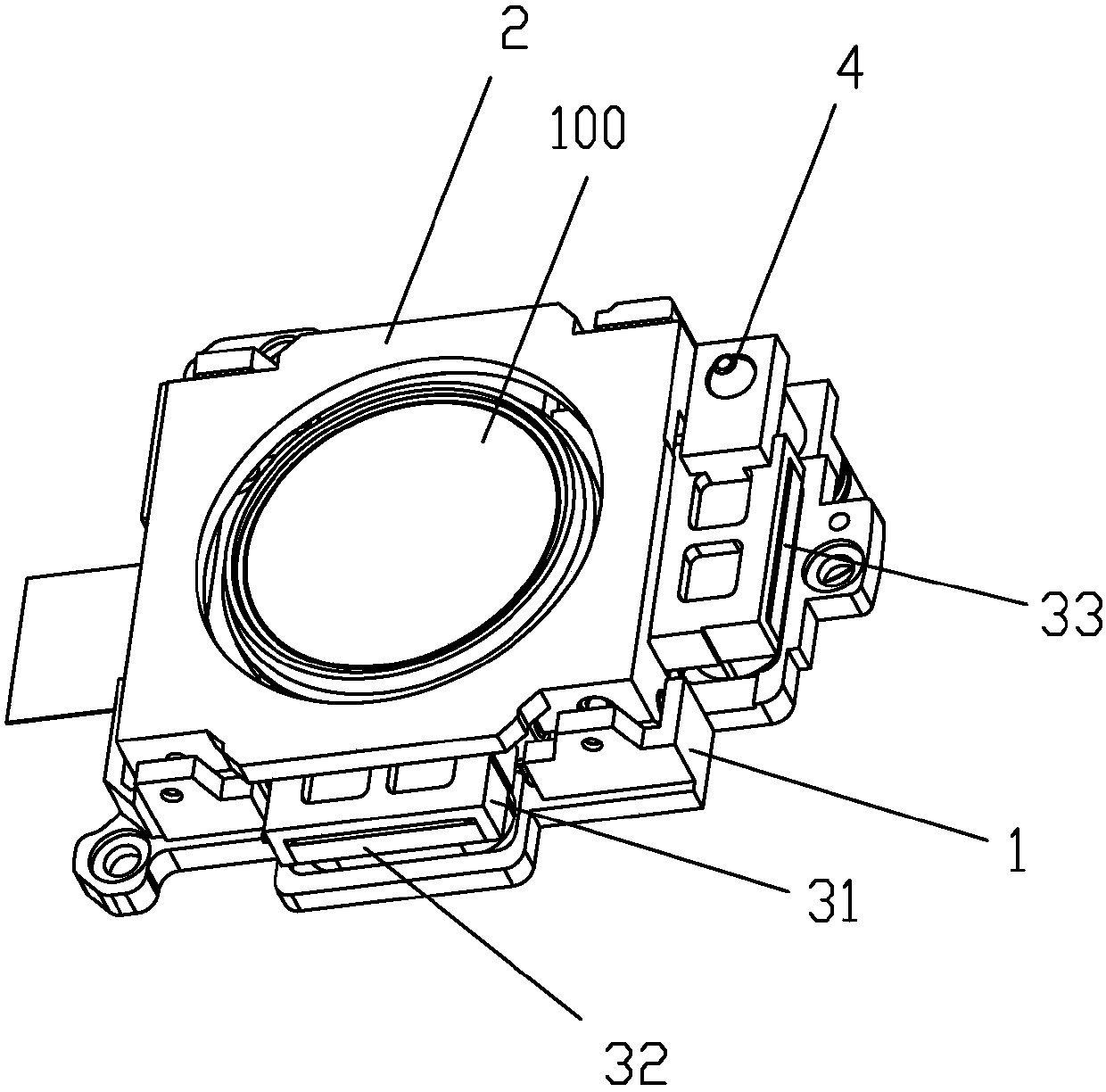

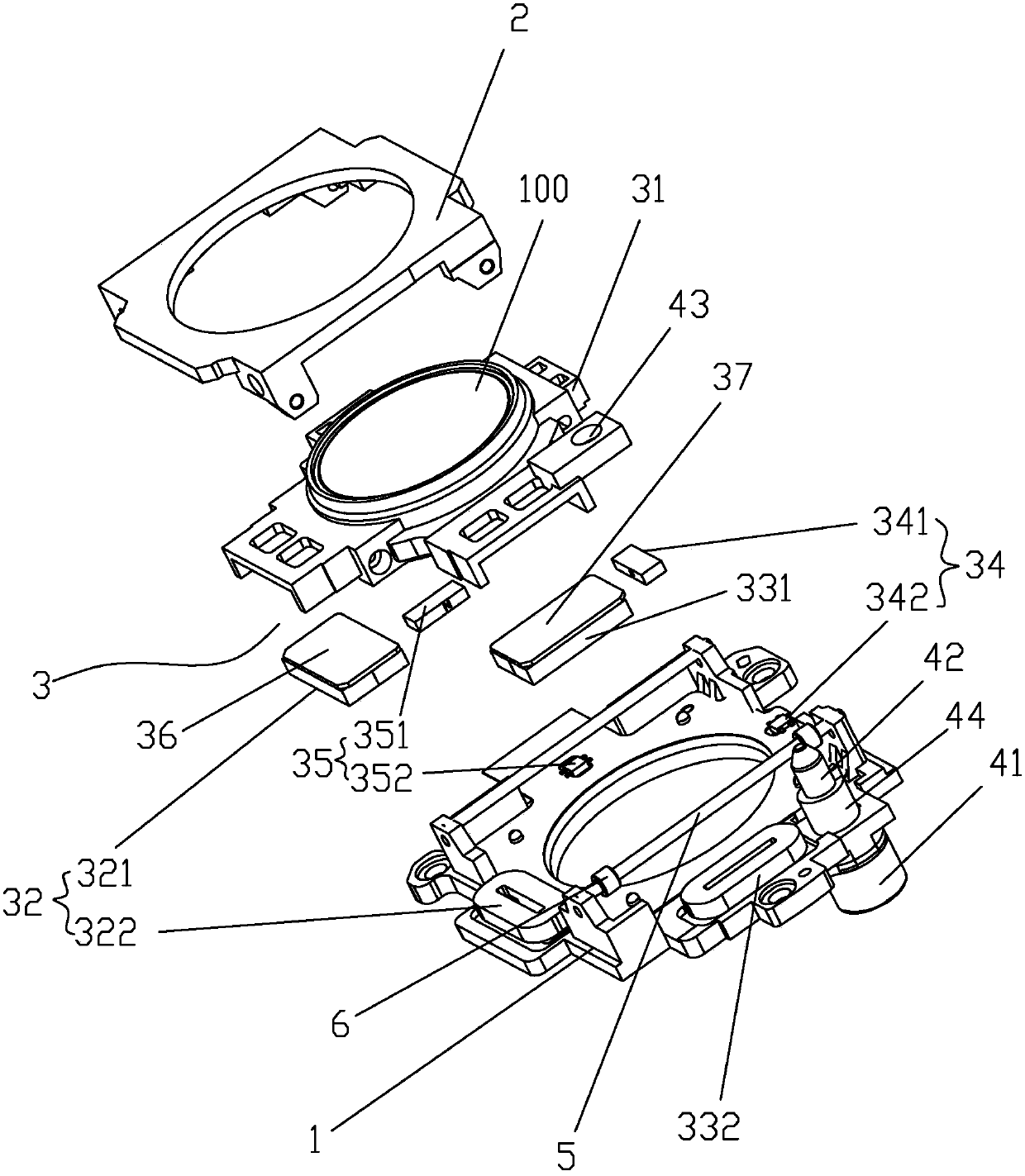

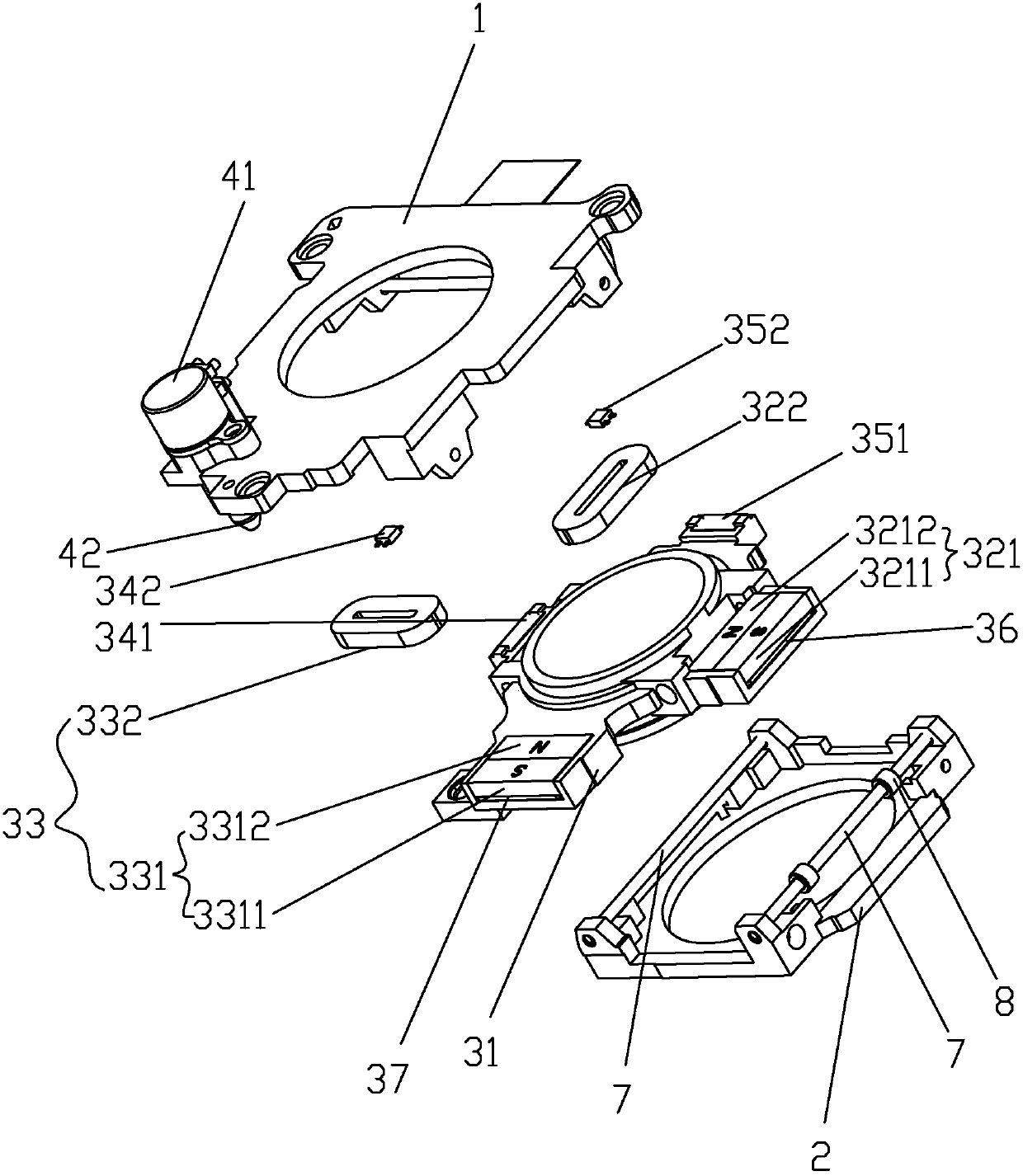

[0031] Such as Figure 1 to Figure 3As shown, a lens anti-shake device with a self-locking structure includes a base 1, and the base 1 is connected with a support frame 2 that can move in the lateral direction relative to it. The support frame 2 and the base 1 There is a lens assembly 3 that can move in the longitudinal direction relative to the support frame 2 and can move in the transverse direction with the support frame 2 relative to the base 1. The lens assembly 3 includes a lens support seat 31 for installing the lens 100, Between the base 1 and the lens support seat 31 are provided a transverse drive assembly 32 and a longitudinal drive assembly 33 which respectively drive the lens assembly 3 to move laterally and longitudinally. The transverse drive magnet assembly 321 and the transverse drive coil 322 opposite to the transverse drive magnet assembly 321 on the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com