Dynamic frictional resistance torque calculating method

A calculation method and torque resistance technology, which are applied in the fields of oil and gas and coal exploration and development to achieve the effect of high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described and elaborated below in conjunction with the accompanying drawings.

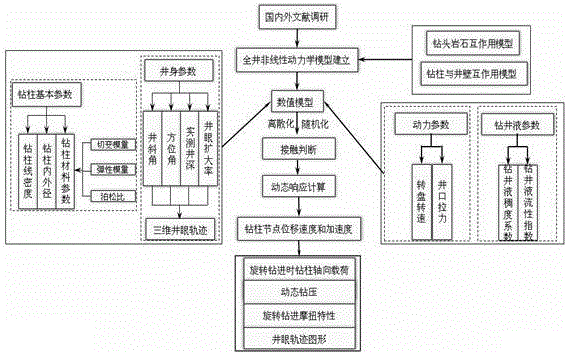

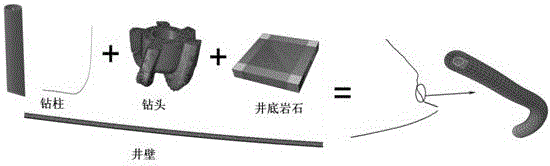

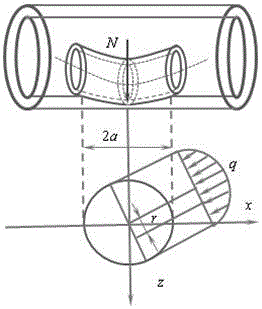

[0028] The present invention is a calculation method of friction torque based on the dynamics of the whole well service pipe string system. The full well system is discretely numericalized by the finite element method, and the friction resistance of the whole well pipe string under complex working conditions is simulated and calculated by using the display integral algorithm. torque value. It is mainly composed of three parts. Firstly, the finite element numerical model based on the service string system of the whole well is established, and then the boundary conditions are applied to the numerical model. Finally, an effective algorithm is used to calculate and analyze the frictional torque of the service string in the long and narrow wellbore. It is characterized in that, the described dynamic frictional torque calculation method based on the dynamics o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com