Novel pressure injection mold

A mold and a new type of technology, applied in the direction of commutator manufacturing, etc., can solve problems such as production waste, achieve the effects of reducing costs, reducing waste, and increasing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

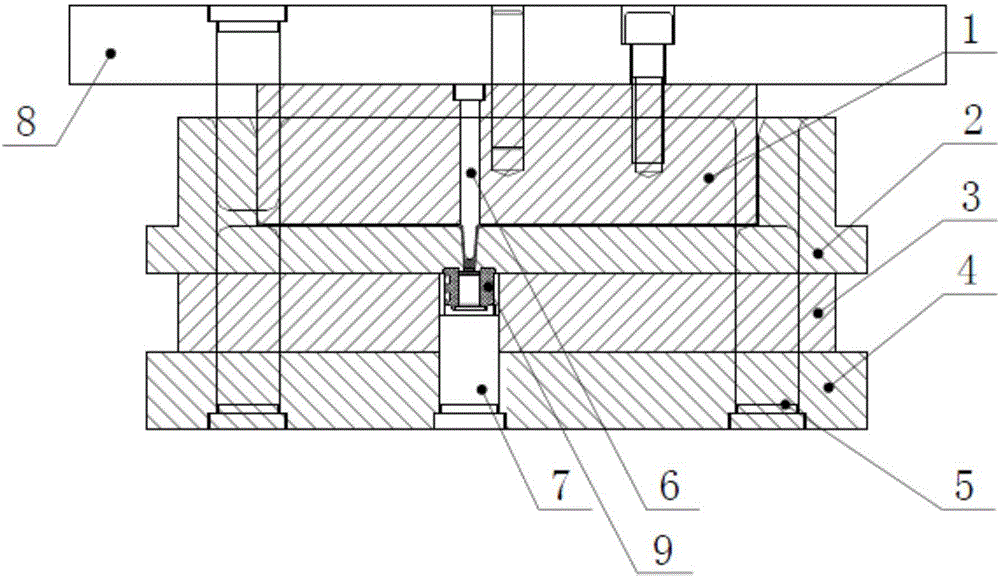

[0015] Such as figure 2 As shown, a new type of injection mold includes a guide post 5, a mounting plate 8, a material block 1, a material chamber 2, a middle mold 3, a lower mold 7 and a lower mold fixing plate 4, and the material block 1 is provided with a series of The main material hole, each of the main material holes is embedded with a guide nail 6, and the lower end of the guide nail 6 is placed in the material chamber 2.

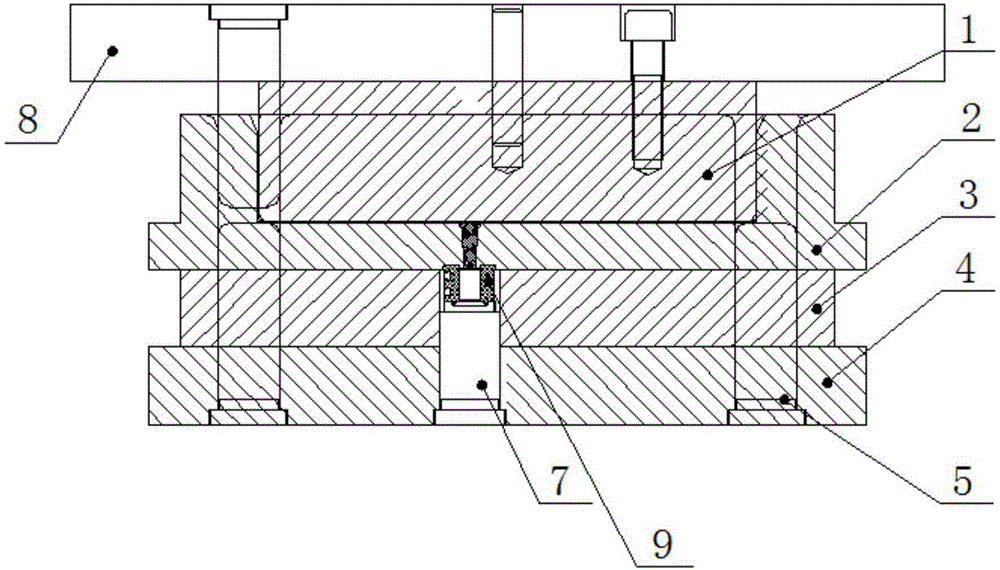

[0016] Compared figure 1 The existing injection mold shown, a new type of injection mold provided by the present invention, reduces the waste of each main material hole by embedding guide nails 6 in the main material holes. Extrusion filling makes the flow speed of bakelite powder faster, and the thickness of the waste left in the bottom layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com