Method for operating a braking system and a braking system

A technology of a braking system and a brake master cylinder, applied in the direction of brakes, etc., can solve the problems of not describing the braking auxiliary system, etc., and achieve the effect of reliable implementation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

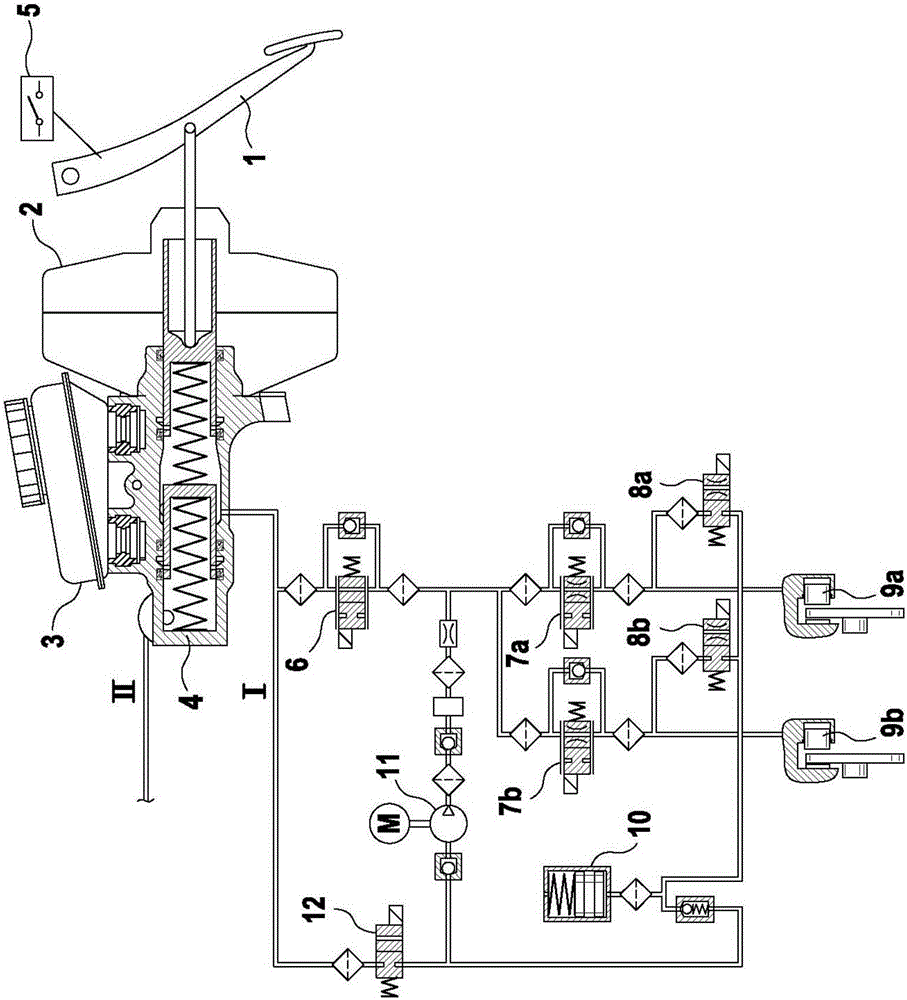

[0026] figure 1 An exemplary braking system of a motor vehicle is shown, with which the method according to the invention can be carried out. The driver-operated brake pedal 1 can be designed with or without auxiliary force support. The driver's braking force acts via the pressure lever, possibly superimposed with the auxiliary force generated by the low brake booster 2 , on the (tandem) brake master cylinder 4 , which is not actuated connected to an unpressurized brake fluid reservoir. Via the brake light switch 5 it can be determined whether the driver has actuated the brake pedal. As an alternative, the brake light switch can also be replaced by a travel sensor, which is arranged, for example, on the master brake cylinder 4 . The brake system has two brake circuits I, II, which (in the case of a four-wheeled vehicle) are each associated with two wheel brakes. Only brake circuit I will be described below, the other brake circuit II expediently having the same design. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com