A heteromethanation catalyst and its molding process and application

A methanation catalyst, catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., to achieve the effect of improving utilization efficiency, improving activity, and increasing active surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

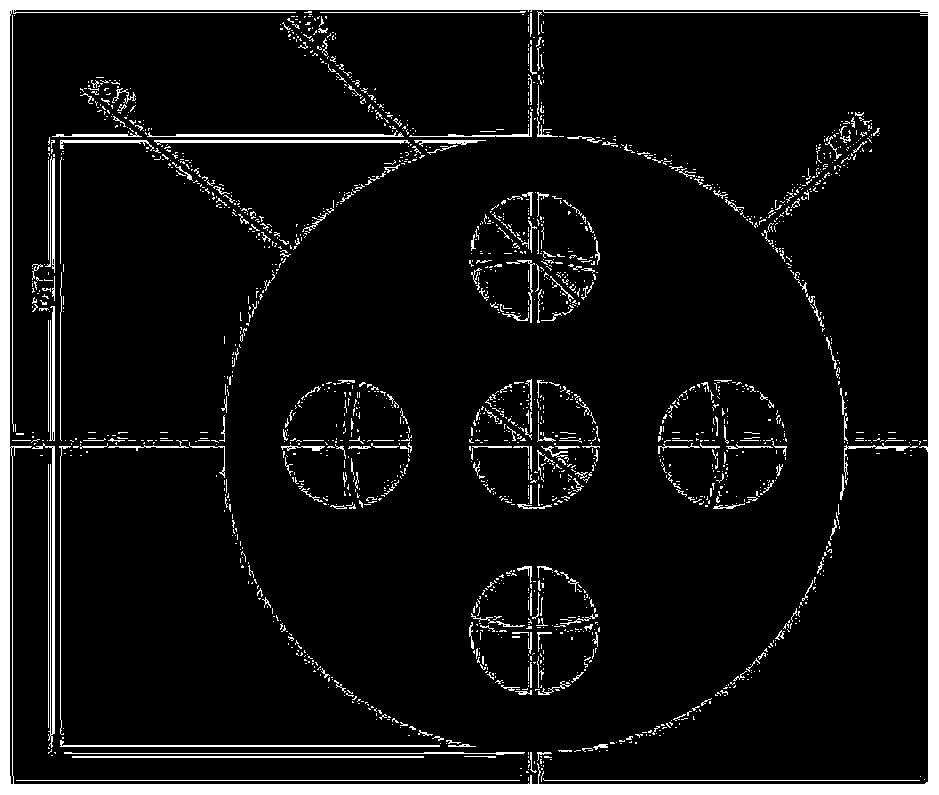

[0044] Mix 1 kg of methanation catalyst powder with a NiO weight percentage of less than 0.15 mm and 22 g of graphite and put it into a wet mixer, and continuously mix 400 ml of the powder with a mass concentration of 3 %HNO 3 The aqueous solution is sprayed onto the surface of the mixed powder in the form of mist, and the wet mixing is continued for 60 minutes after all the liquid is sprayed in. The obtained mixed powder wet material is granulated by a granulator, and then used a chipping machine to make a cylindrical particle catalyst with an outer diameter of Φ18 mm, a height of 10 mm, and 5 through holes of Φ4 mm evenly distributed on the cross section. The catalyst particle surface area / particle skeleton volume ratio is 0.82mm 2 / mm 3 , the maximum radial mass transfer distance is 2.62mm, and the lateral pressure is 154N / cm. Marked as embodiment 1, its cross-sectional structure size sees figure 1 . The above-mentioned methanation catalyst of Example 1 was applied to ...

Embodiment 2

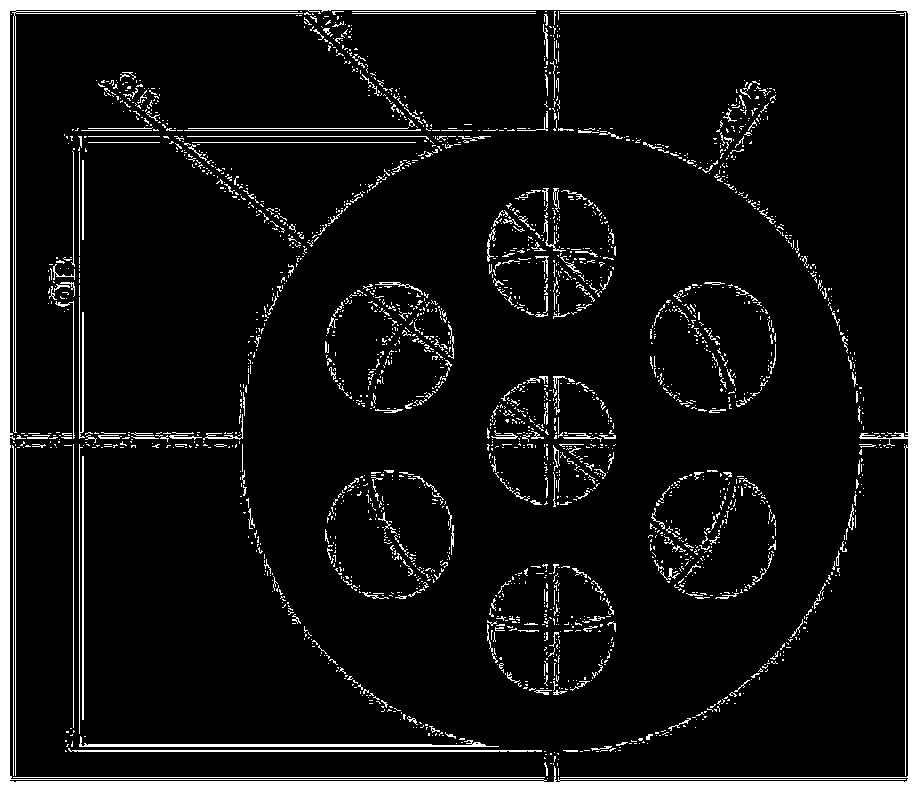

[0046] Mix 1kg of methanation catalyst powder with a particle size of less than 0.15mm and a NiO weight percentage of 45% with 22g of graphite and 50g of 425 cement, then put it into a wet mixer, and continuously 450ml mass concentration is 3% HNO 3 The aqueous solution is sprayed onto the surface of the mixed powder in the form of mist, and the wet mixing is continued for 60 minutes after all the liquid is sprayed in. The obtained mixed powder wet material was granulated by a granulator, and then used a chipping machine to make a cylindrical particle catalyst with an outer circle diameter of Φ18mm, a height of 10mm, and 7 through holes of Φ4mm evenly distributed on the cross section. The catalyst particle surface area / particle skeleton volume ratio is 1.07mm 2 / mm 3 , the maximum mass transfer distance in the radial direction is 1.73mm, and the lateral pressure is 121N / cm. Marked as embodiment 2, its cross-sectional structure size sees figure 2 .

[0047] The above-ment...

Embodiment 3

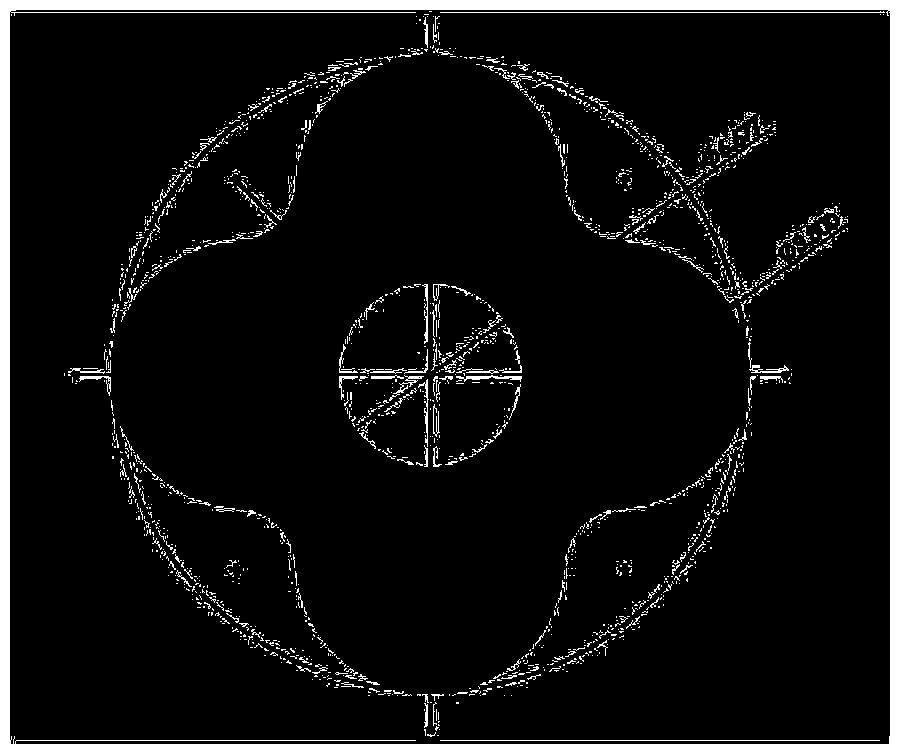

[0049] Mix 1kg of methanation catalyst powder with a particle size of less than 0.15mm and a NiO weight percentage of 60% with 22g of graphite and 50g of 425 cement, then put it into a wet mixer, and continuously 400ml mass concentration is 3% HNO 3 The aqueous solution and 50 ml of polyvinyl alcohol (PVA) with a mass concentration of 3% are sprayed onto the surface of the mixed powder in mist form, and the wet mixing is continued for 60 minutes after all the liquid is sprayed in. The obtained mixed powder wet material is granulated by a granulator, and then made into a cylinder with a circumscribed circle diameter of Φ10mm, a height of 5mm, a Φ3mm through hole in the center of the cross section, and a four-leaf petal shape in the cross section. Particulate catalysts, the dimensions of the cross-sectional structure see image 3 . The catalyst particle surface area / particle skeleton volume ratio is 1.18mm 2 / mm 3 , the maximum mass transfer distance in the radial direction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com