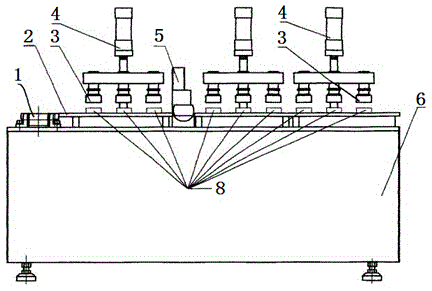

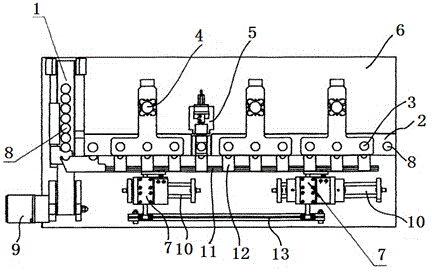

Spray cleaning device for finished bearing

A spray cleaning device and a bearing technology, applied in the field of bearing manufacturing, can solve the problems of inaccurate positioning, inaccurate positioning, easy to bruise the outer surface of the product, etc., and achieve the effect of saving cleaning time and improving cleaning quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] As shown in the figure: Install the working track 2 on the bracket, and there is a sprinkler 3 above the bracket. The sprinkler 3 is installed on the up and down moving mechanism 4 above the bracket, and the horizontal moving mechanism is installed on the bracket. There is a mechanical arm 12 for carrying the workpiece 8 on the working track 2, and the horizontal moving mechanism is composed of a lateral moving mechanism along the workpiece conveying direction and a longitudinal moving mechanism perpendicular to the workpiece conveying direction. Among them, the up and down moving mechanism 4 can drive the shower head 3 to move up and down. When cleaning, the up and down moving mechanism moves down, so that the shower head 3 presses the end face of the finished bearing product, that is, the workpiece 8. After a cleaning station is completed, it moves up and down. The mechanism lifts the sprinkler head 3 up so that the sprinkler head 3 leaves the workpiece 8. At this time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com