Air conditioner liquid storage filter punching mold

A technology for stamping dies and filters, applied in the field of stamping dies, can solve the problems of poor quality of liquid storage filters and die offset, and achieve the effects of improving production efficiency, improving quality and avoiding deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

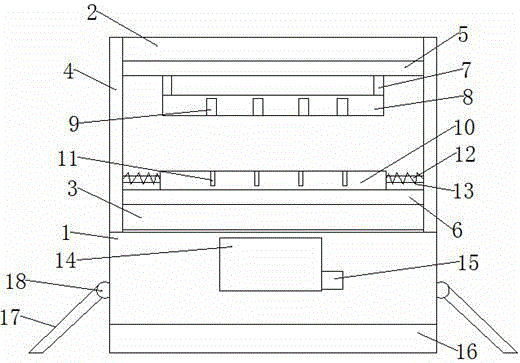

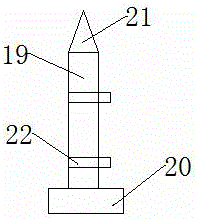

[0016] See figure 1 with figure 2 , The present invention provides a technical solution: an air-conditioning liquid storage filter stamping die, comprising a frame 1, an upper mold base 2 and a lower mold base 3, the frame 1 is provided with a support rod 4, the upper mold base 2 and the lower mold base The mold base 3 is installed on the supporting rod 4, the upper mold base 2 is provided with an upper backing plate 5 at the lower end, the lower mold base 3 is provided with a lower backing plate 6 at the upper end, and the upper backing plate 5 is connected with a discharge plate 8 through a fixed rod 7. A good unloading operation is completed. The unloading plate 8 is provided with a punch 9 to ensure the coaxiality of the equipment. The lower backing plate 6 is provided with a positioning plate 10 at the upper end, and a positioning pin 11 is provided on the positioning plate 10. Position the upper and lower mold bases well, the two ends of the positioning plate 10 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com