A self-consistent microchannel manufacturing method and device based on surface tension

A surface tension and device manufacturing technology, applied in the field of self-consistent surface tension-based microchannel manufacturing methods and devices, can solve the problems of inability to process arbitrary shapes, inability to obtain microchannel devices, inability to process nanoscale microchannels, and the like. The technical means are simple and easy to implement, the longitudinal mechanical properties are improved, and the materials are easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

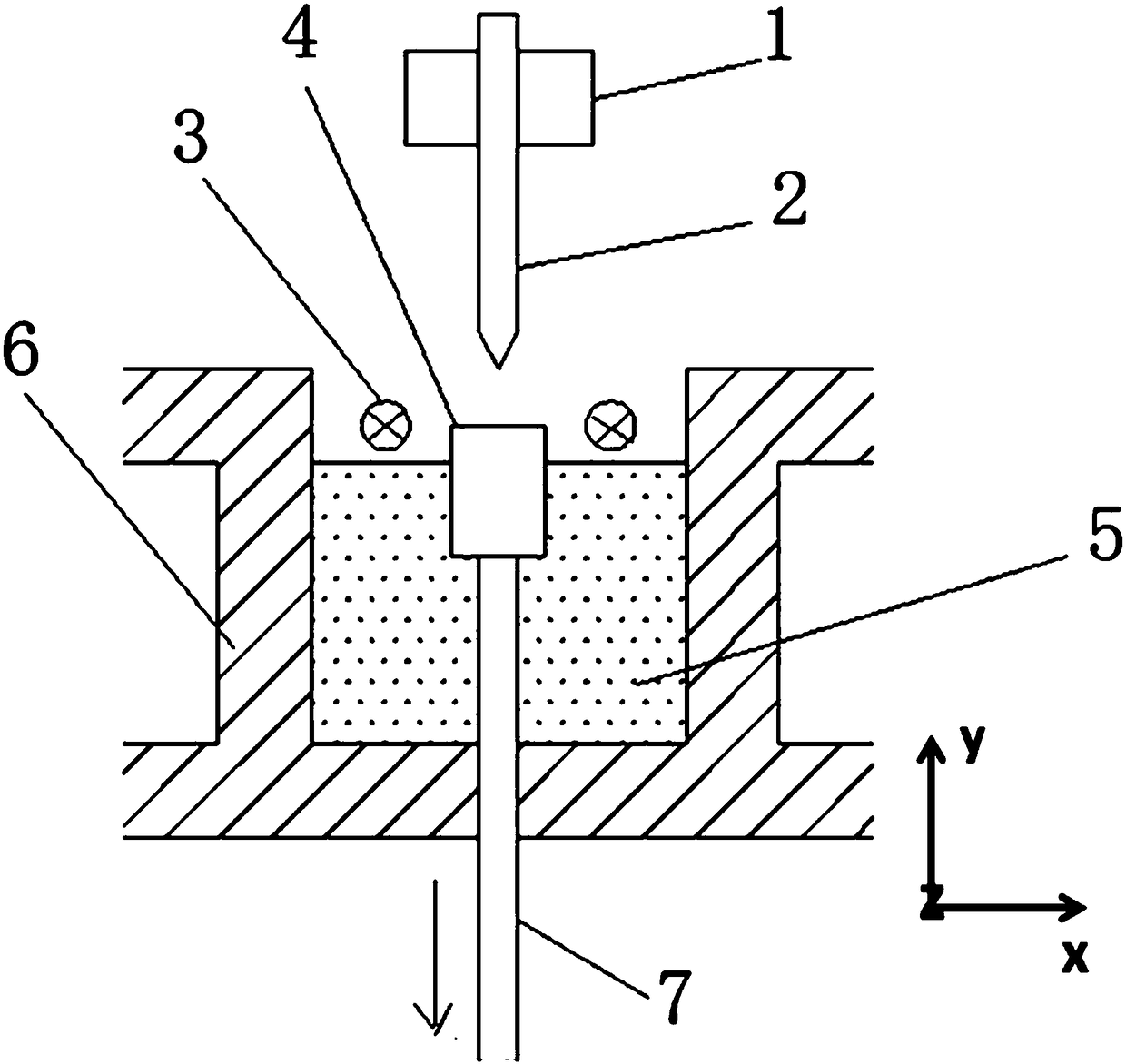

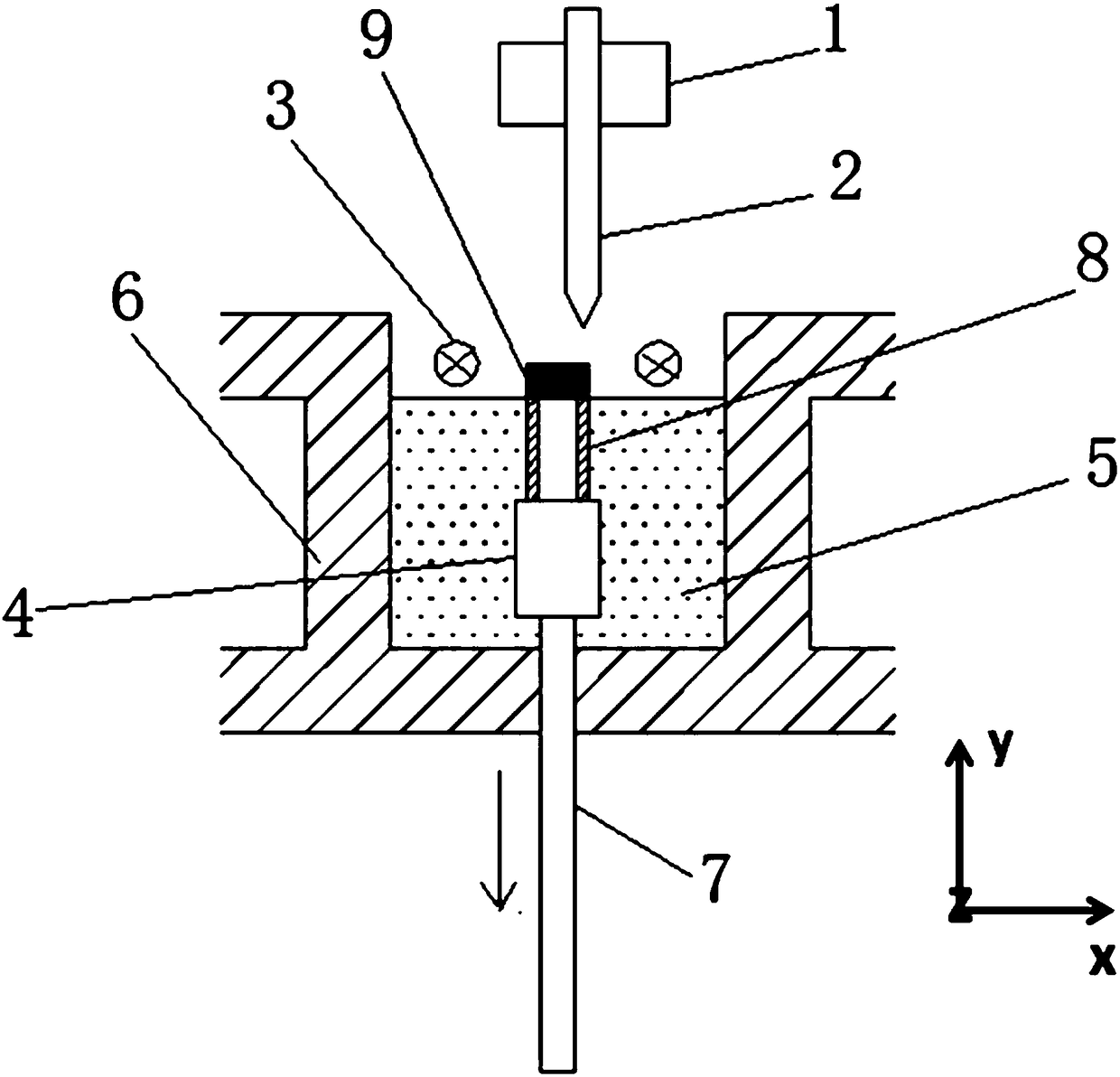

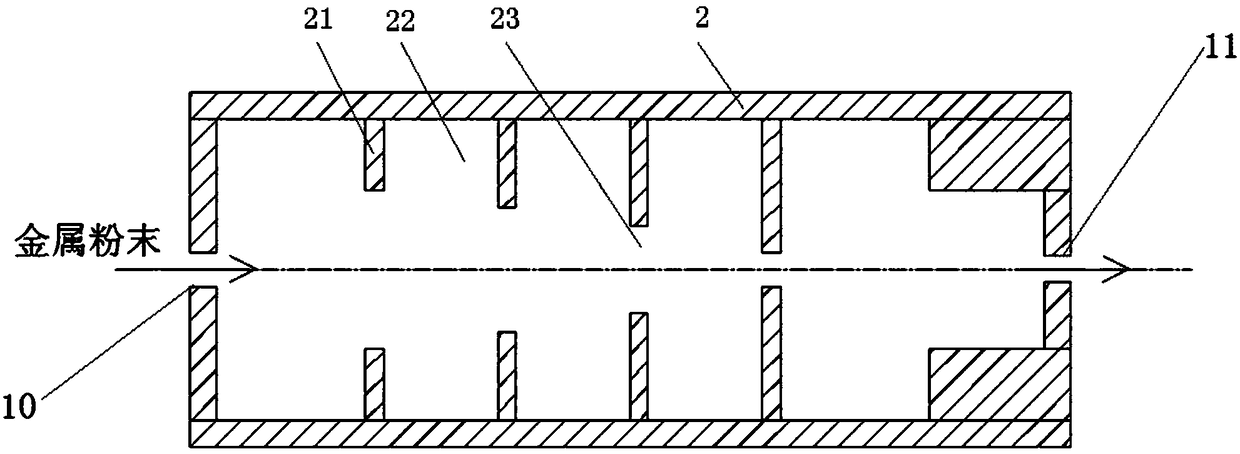

[0047] Such as Figures 1 to 5 shown. The invention discloses a self-consistent microchannel manufacturing device based on surface tension, which includes a cylinder 6 for containing Ga-In liquid alloy 5 (liquid at room temperature), and a cylinder for spraying metal powder arranged above the cylinder 6. Focusing device 2 and control system (not shown in the figure);

[0048] A support platform 4 that can be raised and lowered in the cylinder body 6 is provided in the cylinder body 6; an induction heating station 3 is provided above the liquid level of the Ga-In liquid alloy 5 in the cylinder body 6;

[0049] The focusing device 2 is fixed on the mobile platform 1, and is driven by the mobile platform 1 to move in a two-dimensional (xz) plane; the movement of the mobile platform 1 can be driven by a screw mechanism or a precision gear mechanism well known to those skilled in the art.

[0050] The control system is used to control the support platform 4 to move up or down acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com