Cooling liquid controller used for lathe

A controller and coolant technology, applied in the field of lathes, can solve the problems of forgetting to open, damaged parts, improper operation, etc., and achieve the effect of saving coolant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is further described below in conjunction with accompanying drawing:

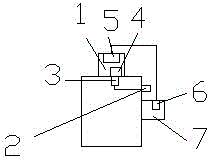

[0011] Such as figure 1 , a coolant controller for a lathe, comprising a liquid storage tank 1, characterized in that the liquid storage tank 1 is connected to a one-way valve 2, and the one-way valve 2 is connected to a liquid outlet 3, and the upper end of the liquid storage tank 1 is provided with The pressure pump 4, the pressure pump 4 is connected to the controller 5, the controller 5 is connected to the temperature sensor 6, and the temperature sensor 6 is arranged on the chuck 7.

[0012] The range of the temperature sensor 6 is greater than 300 degrees.

[0013] The working principle of the present invention is:

[0014] There is a temperature sensor on the chuck. When the temperature is too high, the controller turns on the pressure pump to squeeze out the coolant in the liquid storage tank to cool down the parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com