Reactor core cooling system and reactor core cooling method

A core cooling and core technology, applied in cooling devices, reactors, reducing greenhouse gases, etc., can solve the problem that the cooling process cannot run normally, and achieve the effect of preventing dry burning and saving coolant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

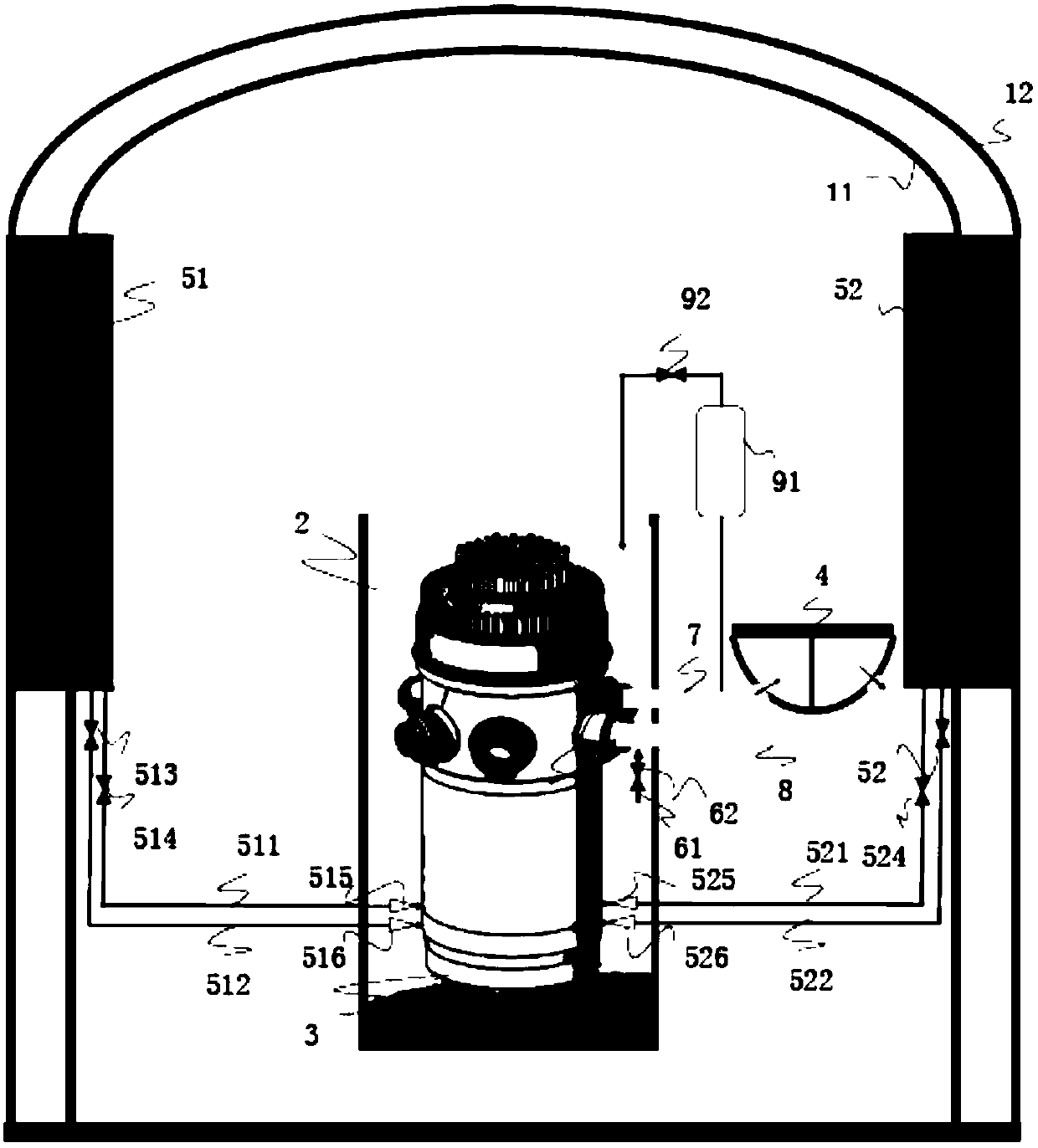

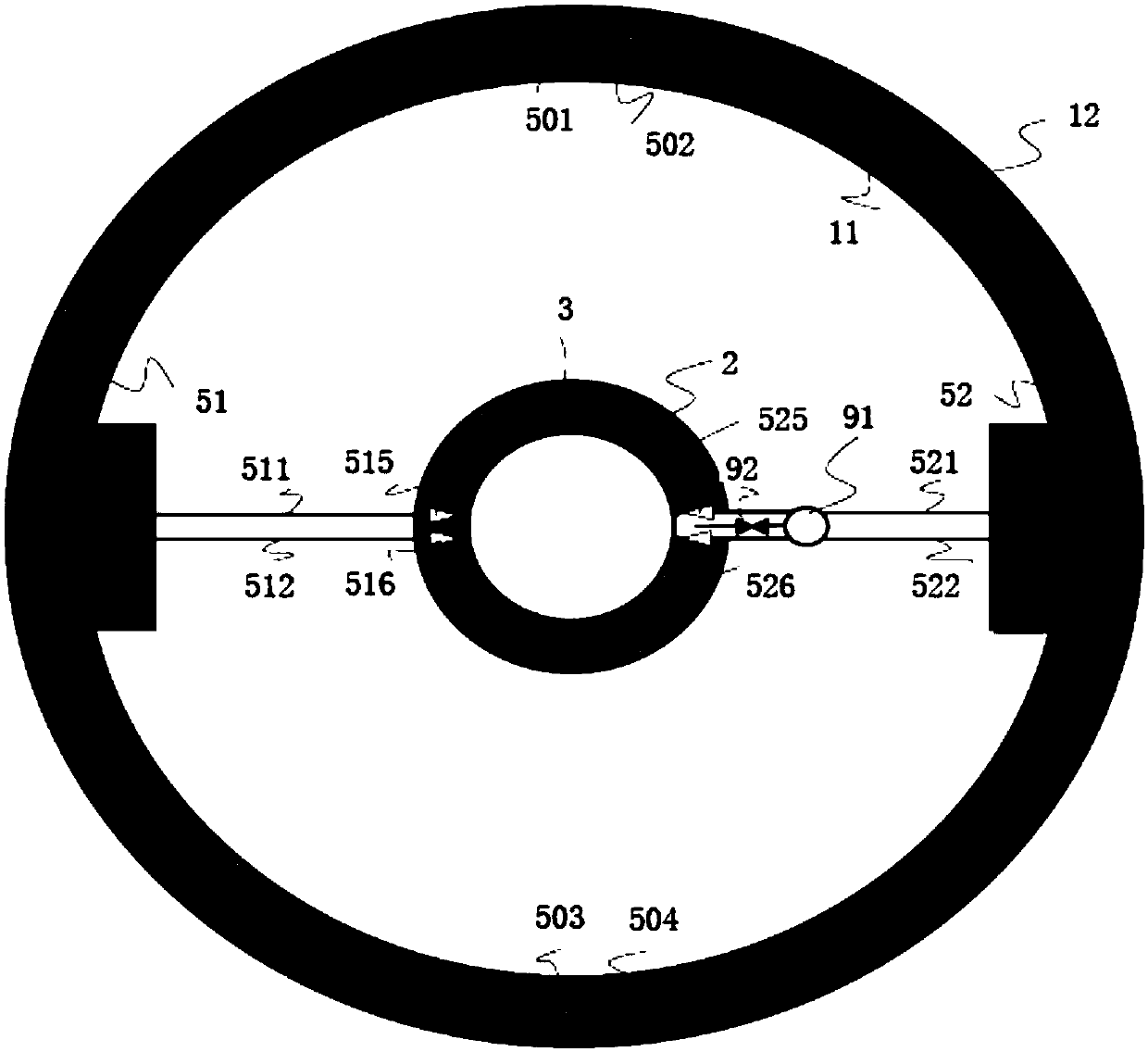

[0031] refer to Figure 1-2 , figure 1 is a cross-sectional view, figure 2 is a top view. In a specific embodiment, the double-sided cooling system of the pressure vessel includes: a double-layer containment vessel, a reactor sump 2, a pressure vessel 3, and a steam generator 4 (only the inlet and outlet chambers of the steam generator 4 are shown in the figure).

[0032] Wherein, the longitudinal section of the double-layer containment vessel is inverted U-shaped, the double-layer containment vessel includes a containment vessel inner wall 11 and a containment vessel outer wall 12, and at least A cooling water chamber for storing coolant. When there are multiple cooling water chambers, the multiple cooling water chambers are arranged along the circumferential direction of the double containment shell. In this embodiment, two left and right cooling water chambers 51 and 52 are formed between the containment inner wall 11 and the containment outer wall 12. It can be underst...

Embodiment 2

[0041] Based on the same inventive concept as the first embodiment, the second embodiment discloses a core cooling method, which is implemented based on the system in the first embodiment. The method of this embodiment includes:

[0042] In the event of a plant-wide blackout in a nuclear power plant, perform the following actions:

[0043] S100. Open the special release valve and water injection valve for the pressurizer, and the water injection pipeline injects coolant into the pressure vessel and the core in a passive manner, and the release pipeline transfers steam, steam-water mixture or coolant from the core into the heat pipe section discharge into said reactor sump;

[0044] S200. When the water level of the reactor water pit rises to a first height, perform step S300; when the water level of the reactor water pit drops to a second height, it is recommended that the first height be taken from the reactor water pit The height corresponding to the top position of , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com