Tire molding machine safety device point inspection system based on picture design and method thereof

A tire building machine and safety device technology, applied in general control systems, control/regulation systems, tires, etc., can solve problems such as potential safety hazards, and achieve the effect of ensuring mandatory, safe and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

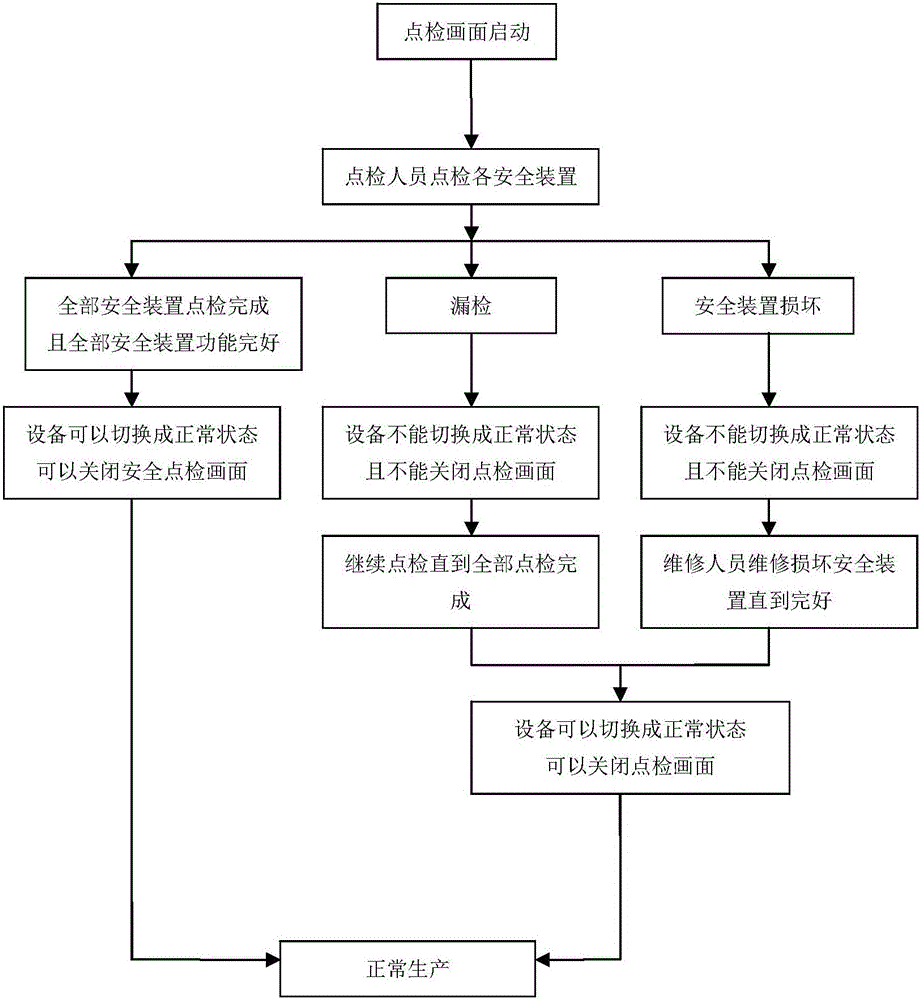

[0014] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] 1. The hardware and software foundation of the point inspection system

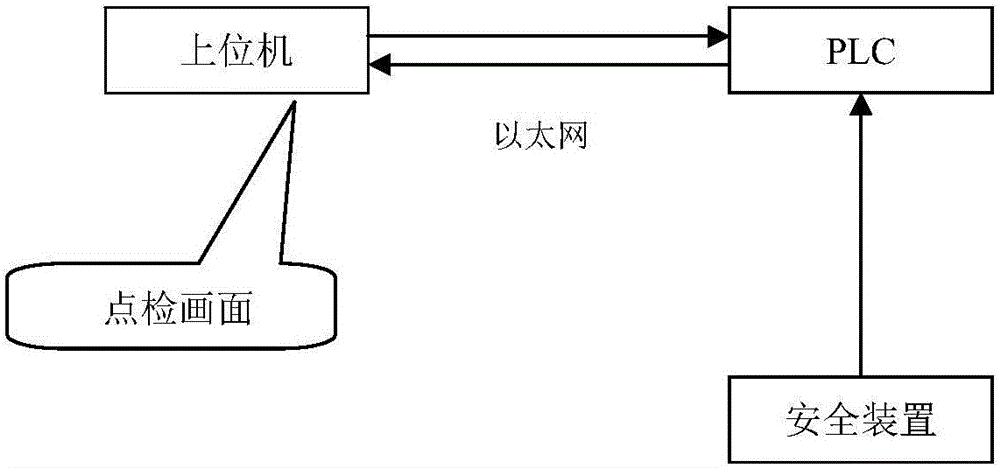

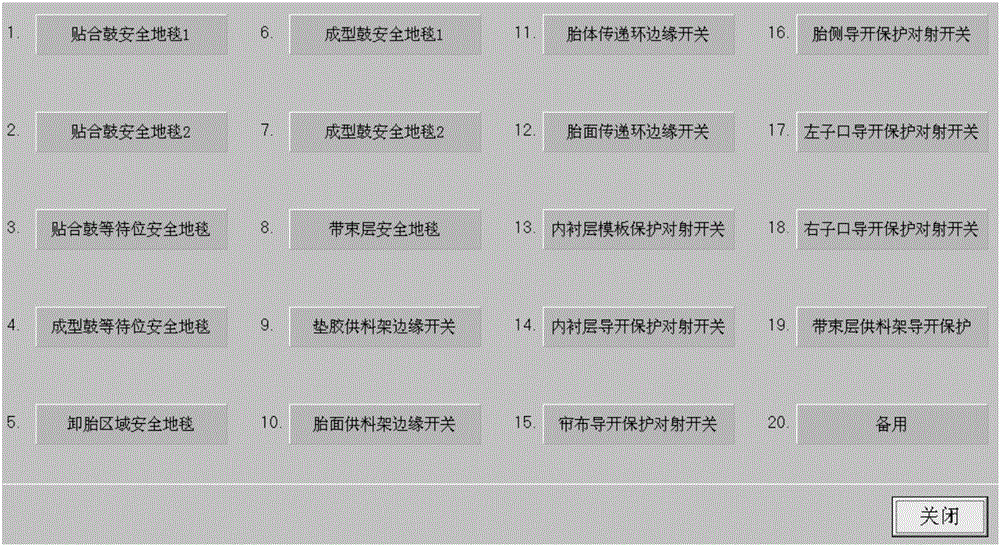

[0016] Such as figure 1 As shown, the hardware foundation of the spot inspection system development is the upper computer, PLC and safety device. The upper computer is an ordinary computer, and the upper computer exchanges data with the PLC through Ethernet. The safety devices we check in the above are electrical safety devices, including safety mats, edge switches and light barriers, etc. The parts used for the safety carpet on the tire building machine of our company are the front part of the transfer ring guide rail, the pad rubber feeding rack, the tread feeding rack, etc. The parts used by the edge switch are the tread feeder, the pad rubber feeder, the tread transfer ring, the carcass transfer ring, etc. The parts where the grating is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com