Automatic horizontal dimming system for automotive headlamps and dimming method

A technology of automobile headlights and headlights, which is applied in the field of automobile headlights and dimming systems, can solve problems such as high cost and complex structure of automatic dimming systems, and achieve the effect of reducing costs and simplifying the dimming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] Embodiment of automatic horizontal dimming system:

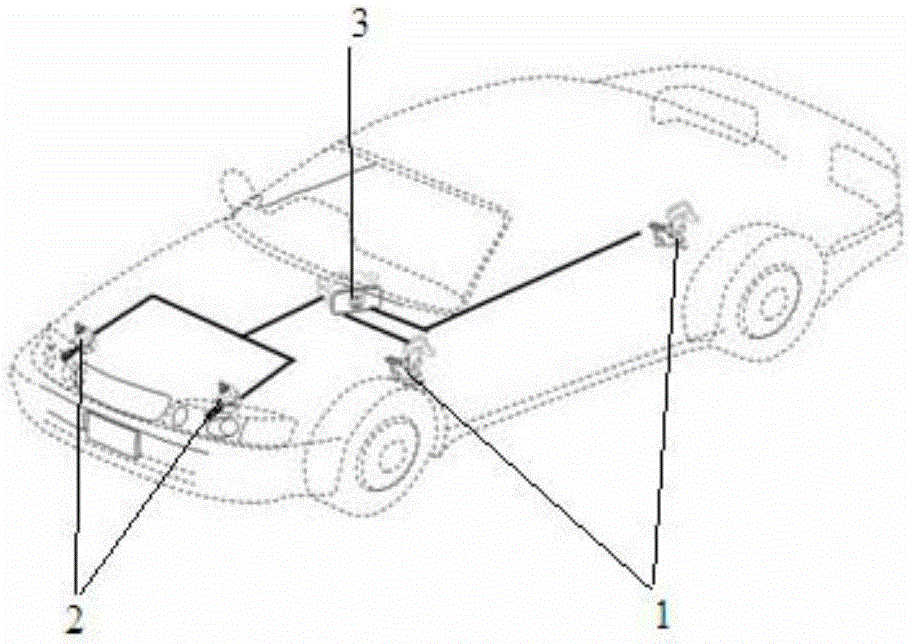

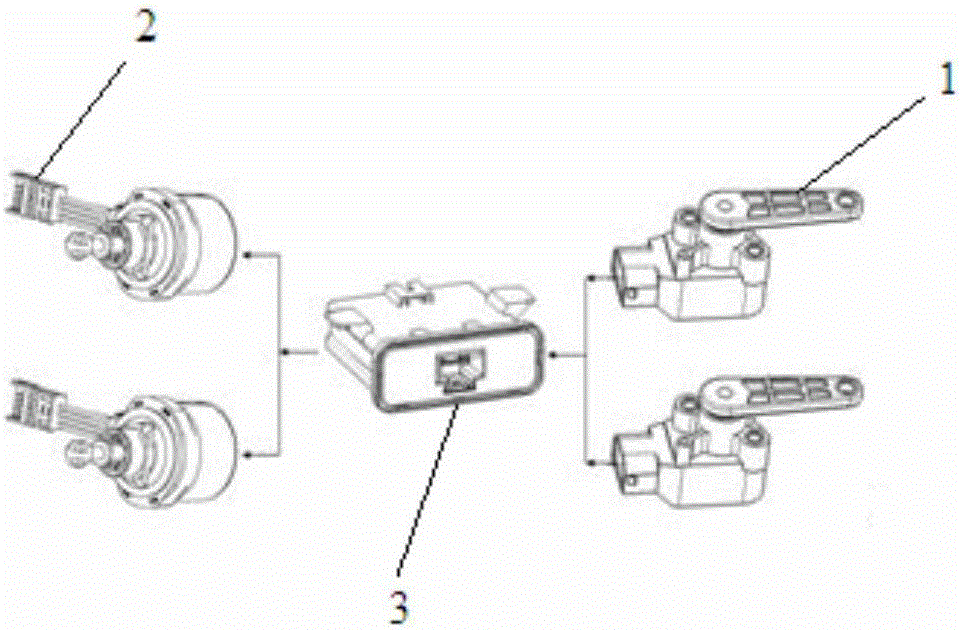

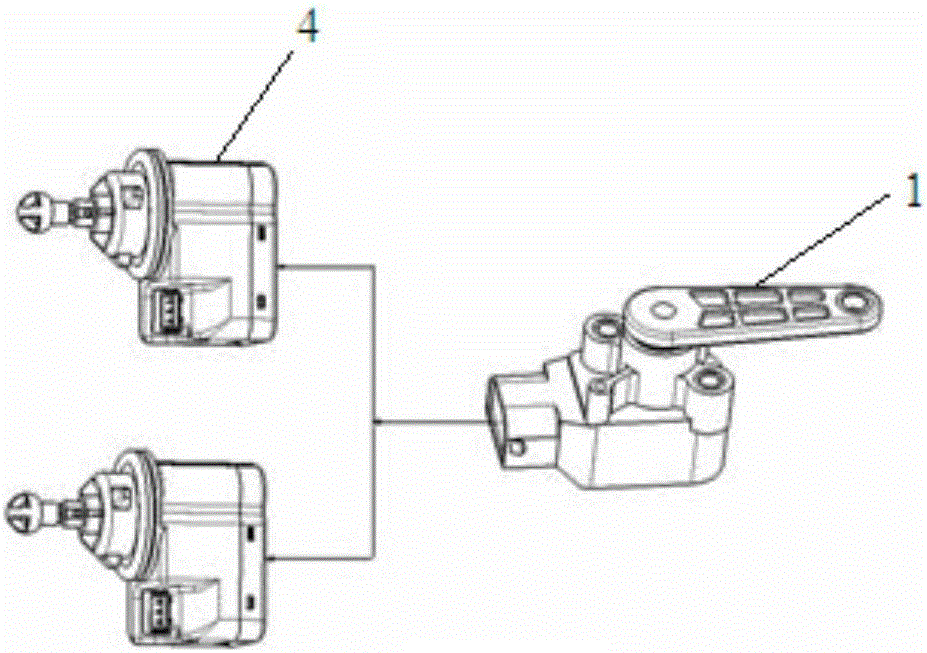

[0041] Such as image 3 As shown, the automatic horizontal dimming system of the present invention includes a vehicle body height sensor for detecting changes in vehicle body height and two DC motors for controlling the irradiation direction of the headlights.

[0042]One end of the vehicle body height sensor is fixed on the part where the height of the chassis suspension and the body remains constant, and the other end is fixed on the part that moves relatively between the chassis suspension and the body. When the height of the vehicle body changes, the sensor swing arm will follow When the angular deflection occurs, the sensor swing arm will output different voltage signals correspondingly at different angles.

[0043] In a preferred embodiment, the vehicle body height se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com