Unmanned surface vehicle laying and retrieving method

A recycling method and technology for aircraft, applied in the directions of ships, ship safety, transportation and packaging, etc., can solve the problems of high difficulty, high operation risk and high cost, and achieve the effect of avoiding damage, simple operation and high success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

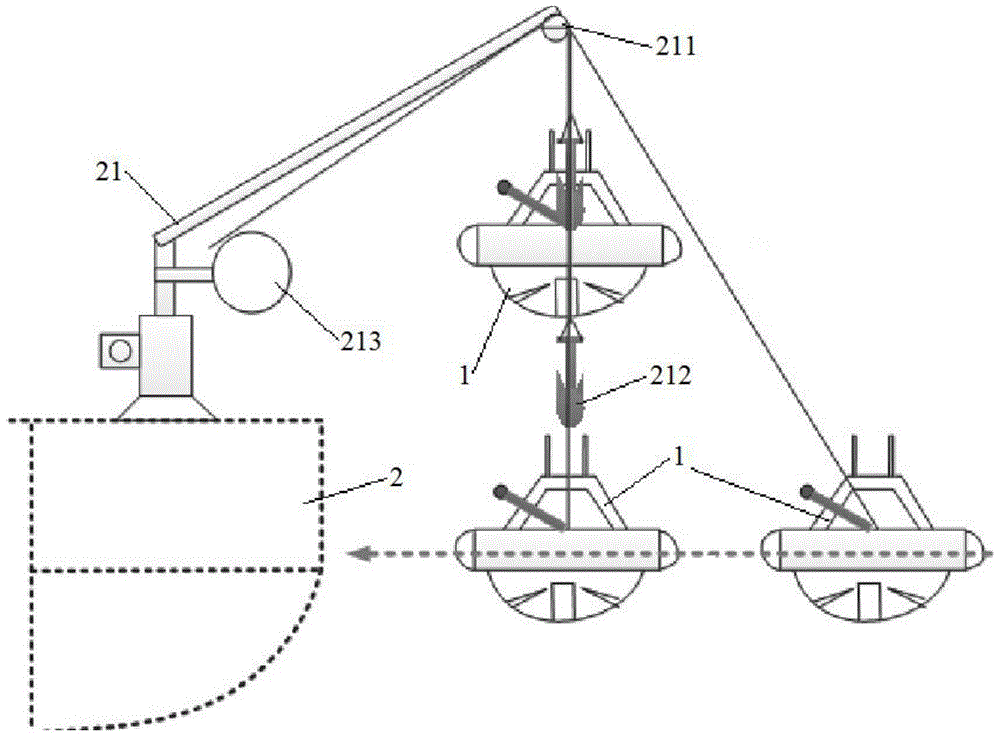

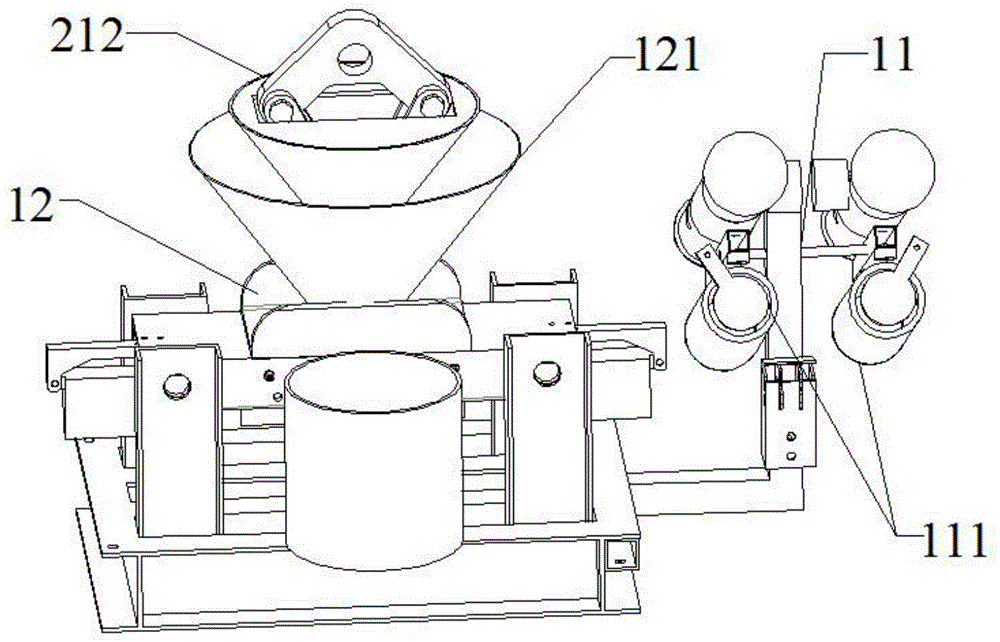

[0023] A deployment and recovery method for an unmanned surface vehicle, the unmanned surface vehicle 1 is equipped with a rope-throwing device 11 and a crane system 12, the rope-throwing device 11 is provided with a launching barrel 111, and compressed air is used for launching It should be noted that this deployment and recovery method includes the method of deploying and recovering the unmanned surface vehicle 1 by the mother ship 2 and the hoisting module 21 installed on the edge of the mother ship 2, and the steps are as follows:

[0024] (1) After adjusting the direction of the mother ship 2, stop sailing and enter the deployment and recovery preparation state, and perform anchoring and positioning;

[0025] (2) Remotely control the unmanned surface vehicle 1 so that its head orientation is consistent with the bow orientation of the mother ship 2, and drive the unmanned surface vehicle 1 to 5 meters on the port side of the mother ship 2, such a distance is within the rang...

Embodiment 2

[0038] The rope throwing device 11 can also use more efficient electromagnetic ejection or adopt a more economical spring elastic rope to launch the traction rope, and use a hook to replace the tapered hammer 212, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com