Self-adaptive gripper for bag packages

A self-adaptive, bag packaging technology, applied in packaging and other directions, can solve the problems of not having the adjustable grip width function, single function, and inability to grasp at the same time, and achieve a wide range of use, simple manufacture, and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

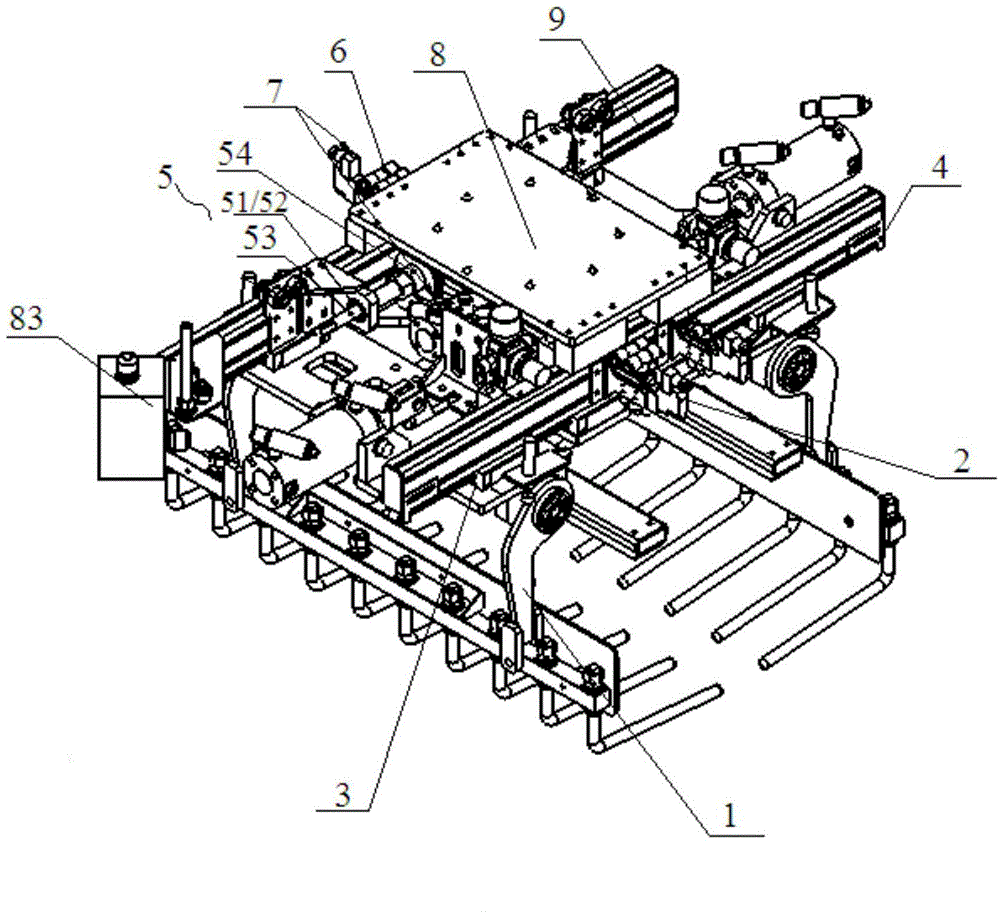

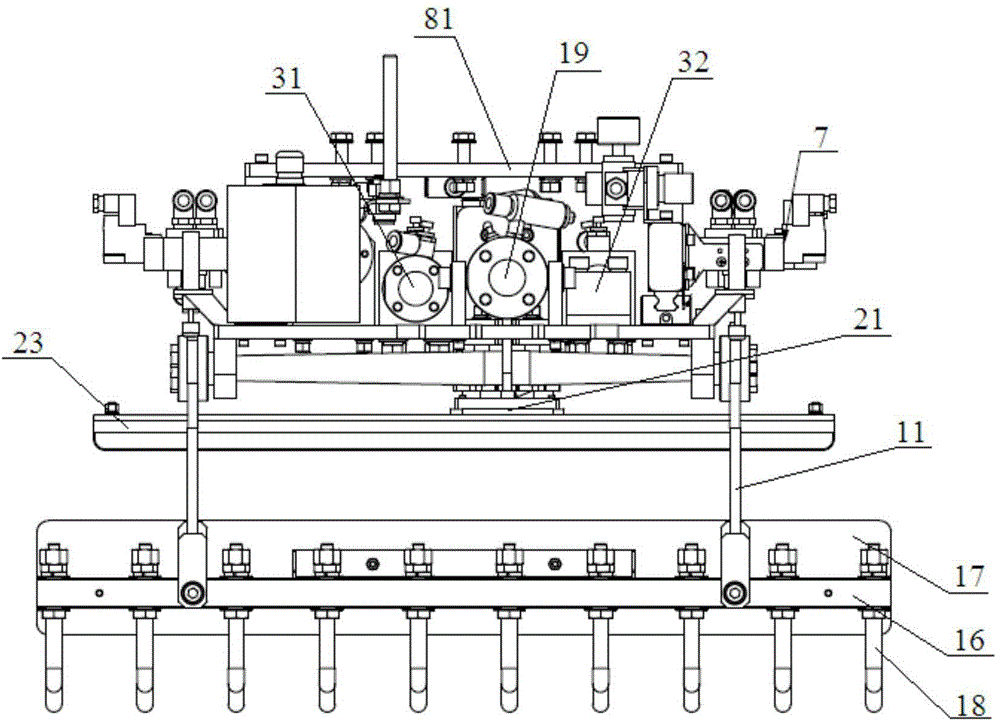

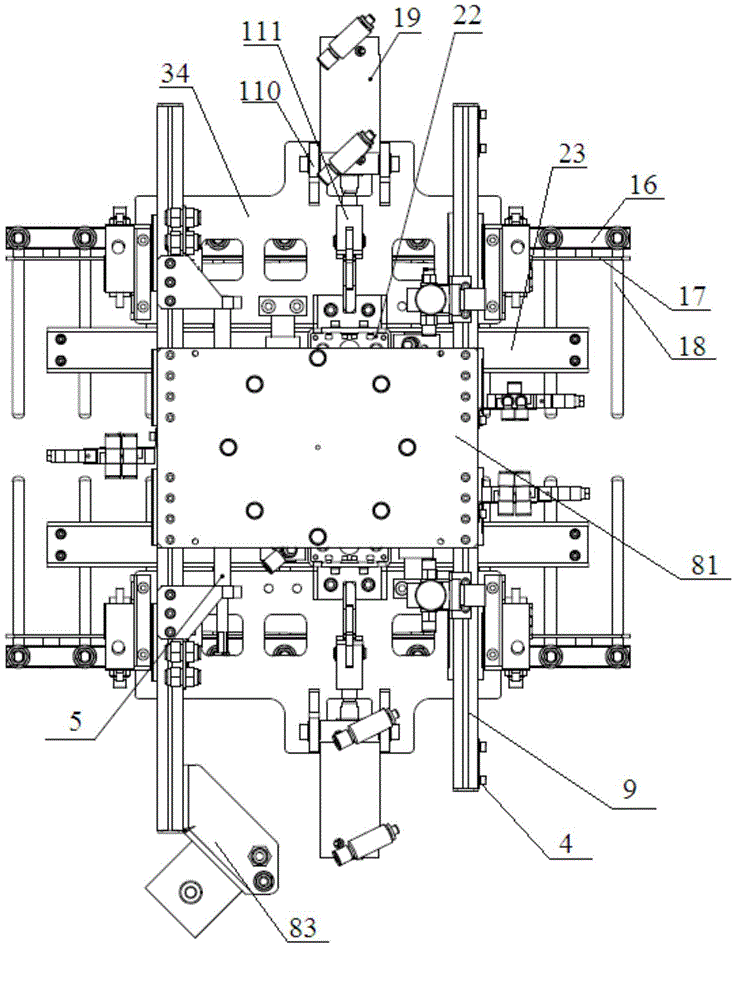

[0031] Such as Figure 1 ~ Figure 4As shown, a self-adaptive gripper for bag packaging includes two main connecting frames 9 arranged in parallel, a main connecting platform 8 fixedly connected above the main connecting frame 9 for connecting with the end of the robot, and located below the main connecting frame 9 Two clamping units 1 and two pressing units 2 for clamping and grabbing materials, of which the two holding units 1 and the two pressing units 2 are mirror symmetrically arranged, and also include an automatic width adjustment unit 3 and Width manual fine-tuning unit 5 also includes controllers for linkage control of clamping unit 1, compacting unit 2 and automatic width adjustment unit 3. It is connected with different cylinders in the clamping unit 1, the pressing unit 2 and the automatic width adjustment unit 3. The gas circuit connection unit 6 includes a connecting pipe 61 and a gas pipe joint 62 , and the gas circuit control unit 7 includes a solenoid valve 71...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com