Wall and floor brick warehousing system convenient for realizing automatic storage and taking

A warehousing system and technology of wall and floor tiles, applied in the field of warehousing of wall and floor tiles, can solve the problems of difficult automation, time-consuming and labor-intensive, high labor costs, etc., and achieve the effect of convenient automatic access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

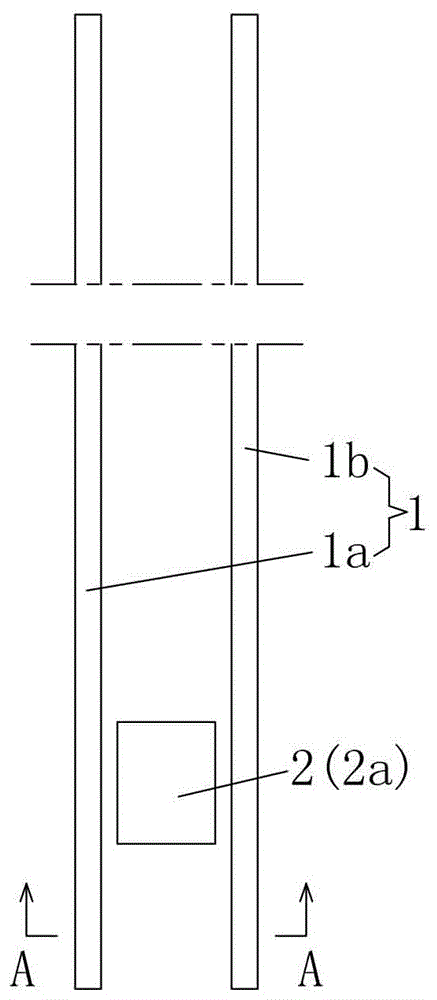

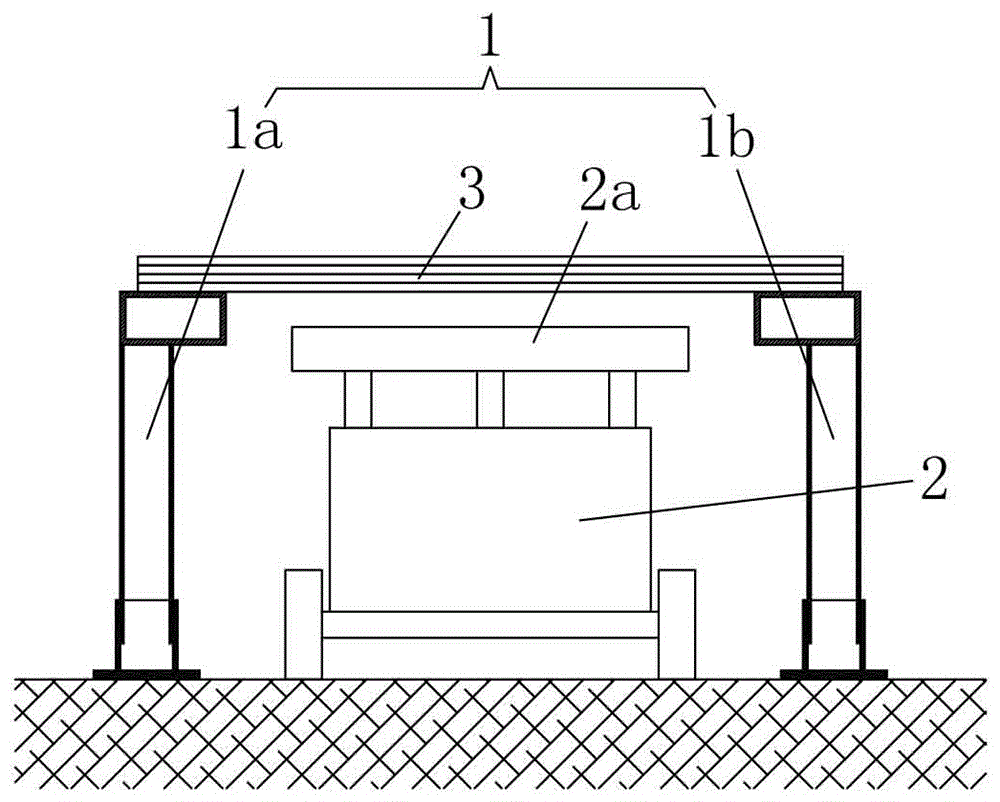

[0022] see figure 1 , figure 1 It is a top view of the whole wall and floor tile storage system of the present embodiment. The storage system is provided with a tunnel 1 for placing adobes, and a brick transport trolley 2 walking along the tunnel is arranged in the tunnel 1 . see also figure 1 , figure 2 , the tunnel 1 is composed of two rows of steel support frames 1a and 1b fixed on the ground, and the top of the entire tunnel 1 is open. Such as figure 2 As shown, the adobe 3 stored in the tunnel 1 spans the opening at the top of the tunnel, and the adobe 3 is supported by the tops of the two side walls of the tunnel, that is, the tops of the two rows of steel support frames 1a, 1b. The length of the tunnel 1 depends on the quantity of brick adobes that need to be stored, and the longer the tunnel, the more brick adobes can store.

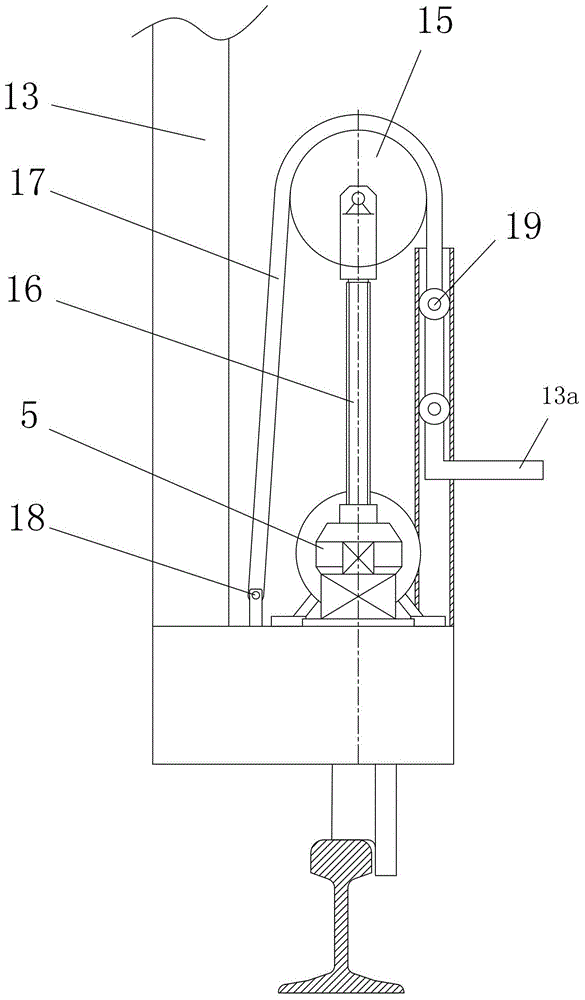

[0023] Such as figure 2 As shown, the brick transport trolley 2 is provided with a lifting platform 2a for carrying brick adobes. The...

Embodiment 2

[0026] see Figure 4 , the present embodiment has been further improved on the basis of Embodiment 1: one end of the tunnel 1 is provided with a stacker 6 and a transmission line 7 connected with the kiln, and the other end of the tunnel 1 is provided with a destacker 8 and a The transmission line 9 connected to the downstream equipment. Stacker 6 and unstacker 8 can adopt existing similar equipment. Because the structure of stacker 6 and unstacker 8 is more complicated, and the present invention does not relate to the concrete structure of stacker 6 and unstacker 8, for making view clear, Figure 4 The stacker 6 and the destacker 8 are abstractly represented by only one dotted frame. When storing adobes, the adobes output from the kiln are arranged one by one on the transmission line 7 connected to the kiln, and the adobes sent by the transmission line 7 are piled up on the top of one end of the tunnel 1 by the stacker 6, for example It can be that three, four or five bric...

Embodiment 3

[0028] see Figure 6 , this embodiment is further extended on the basis of Embodiment 2: with Embodiment 2, namely Figure 4 The system shown as an expansion unit is expanded into two units, and the transmission lines at both ends of the tunnel of the two units are respectively connected to a main transmission line, wherein the two transmission lines 7 located at the same end of the tunnel 1 are connected to a main transmission line 10, the two transmission lines 9 at the other end of the tunnel 1 are connected to another main transmission line 11. In this way, different transmission lines can be used to sort bricks of different varieties: the bricks of different varieties output from the kiln can be sent to two units respectively through the main transmission line 10 and two transmission lines 7, so that the tunnels 1 in the two units Different types of adobes are stored respectively. Similarly, the adobes stored in the tunnels 1 in the two units can be transferred to the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com