Automatic bolt righting machine

A bolt, automatic technology, applied in the field of automatic bolt straightening machine, can solve the problem of non-uniform direction of the screw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

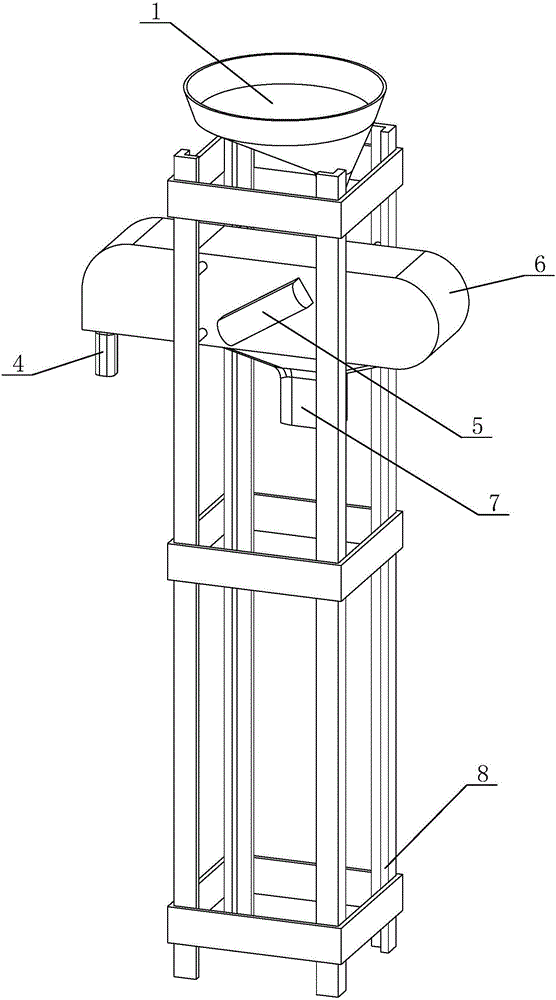

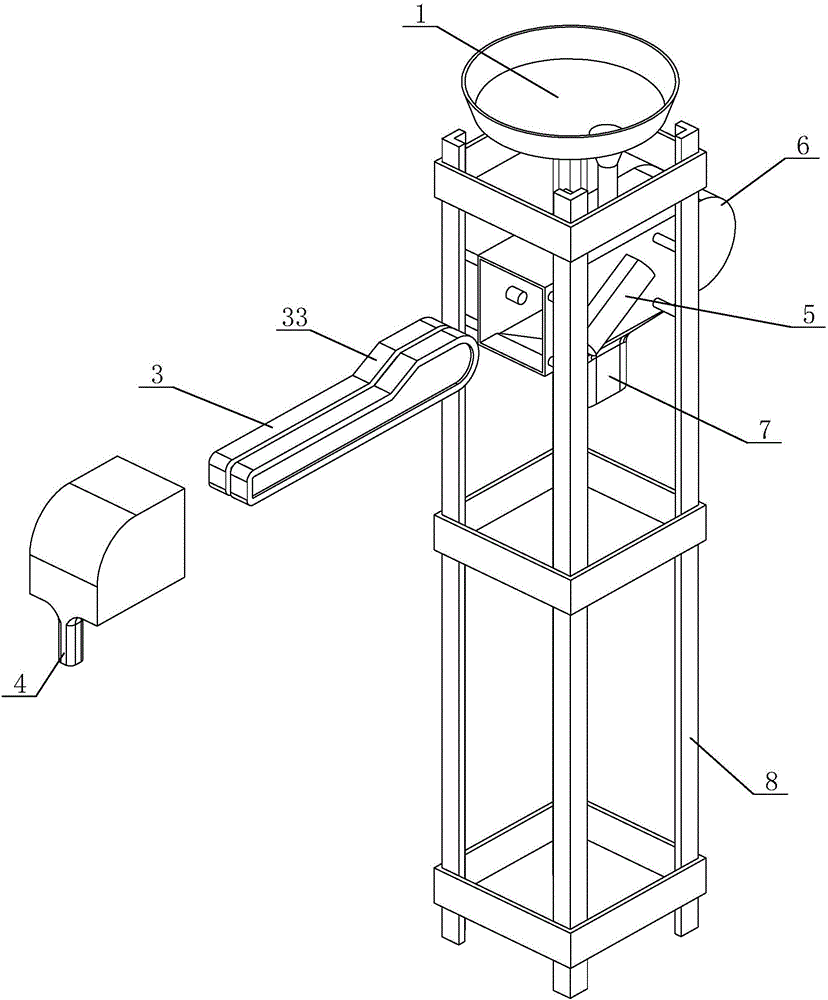

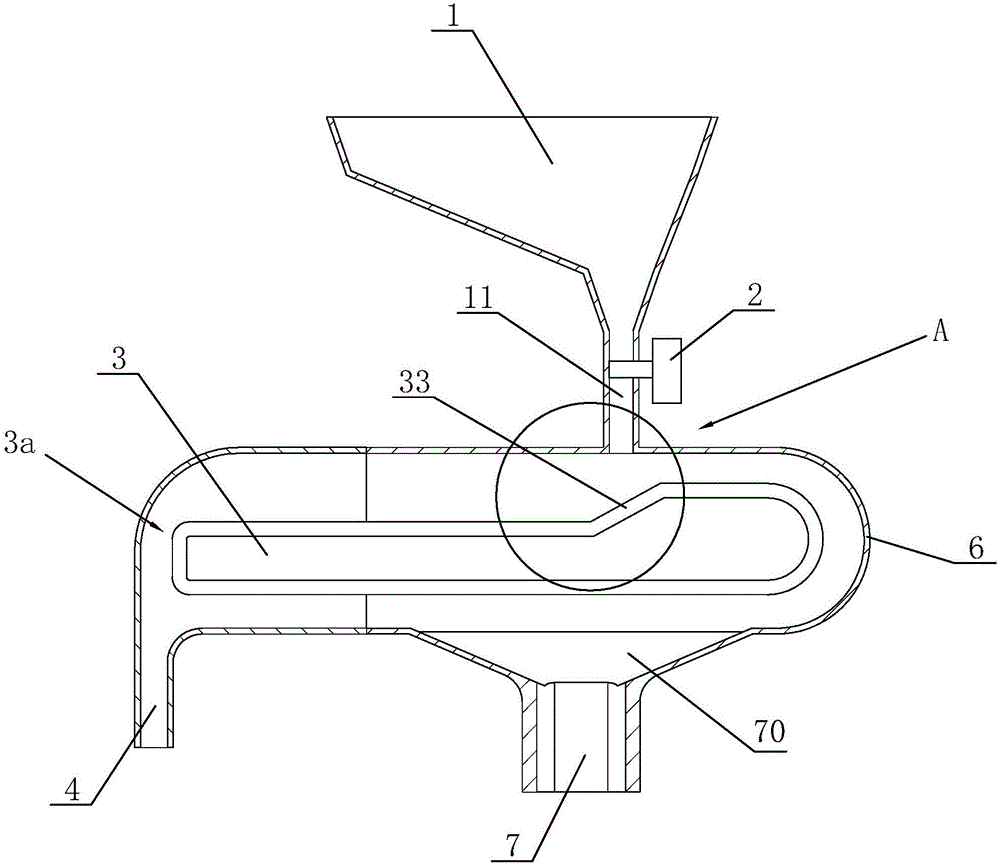

[0024] The present invention will be further described below in conjunction with the drawings.

[0025] The storage hopper 1 is responsible for adding bolts to the automatic bolt straightening machine through the conveying pipe 11 to maintain the normal operation of the machine;

[0026] The valve 2 is located on the side of the feed pipe 11, and is equipped with a timing open and close switch, which is responsible for timing the opening and closing of the feed pipe 11 to achieve the speed and time of managing the feeding. The opening and closing interval can be 1 second. It is ensured that the bolts of the feed pipe 11 falling on the conveyor belt 3 within one second within at least one second can effectively prevent the phenomenon of bolt stacking on the conveyor belt.

[0027] The conveyor belt 3 is the main working part of the entire automatic bolt straightening machine, which is responsible for receiving the bolts dropped from the feed pipe 11 and changing the direction of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com