a connecting line

A technology of connecting wires and telescopic cylinders, which is applied in the processing of brake pads, can solve the problems of high labor intensity, poor process consistency, and low efficiency of operators, and achieve the effects of high work efficiency, strong practicability, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

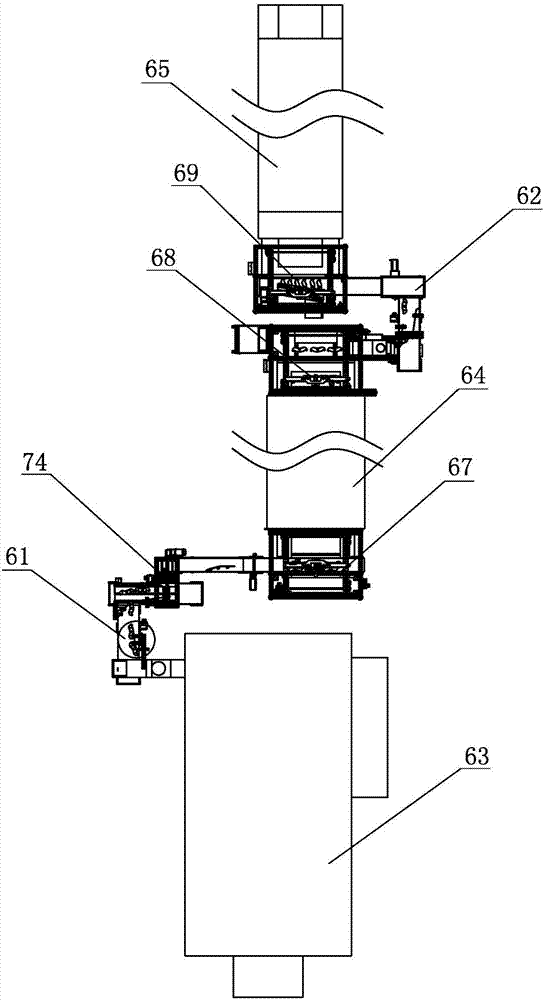

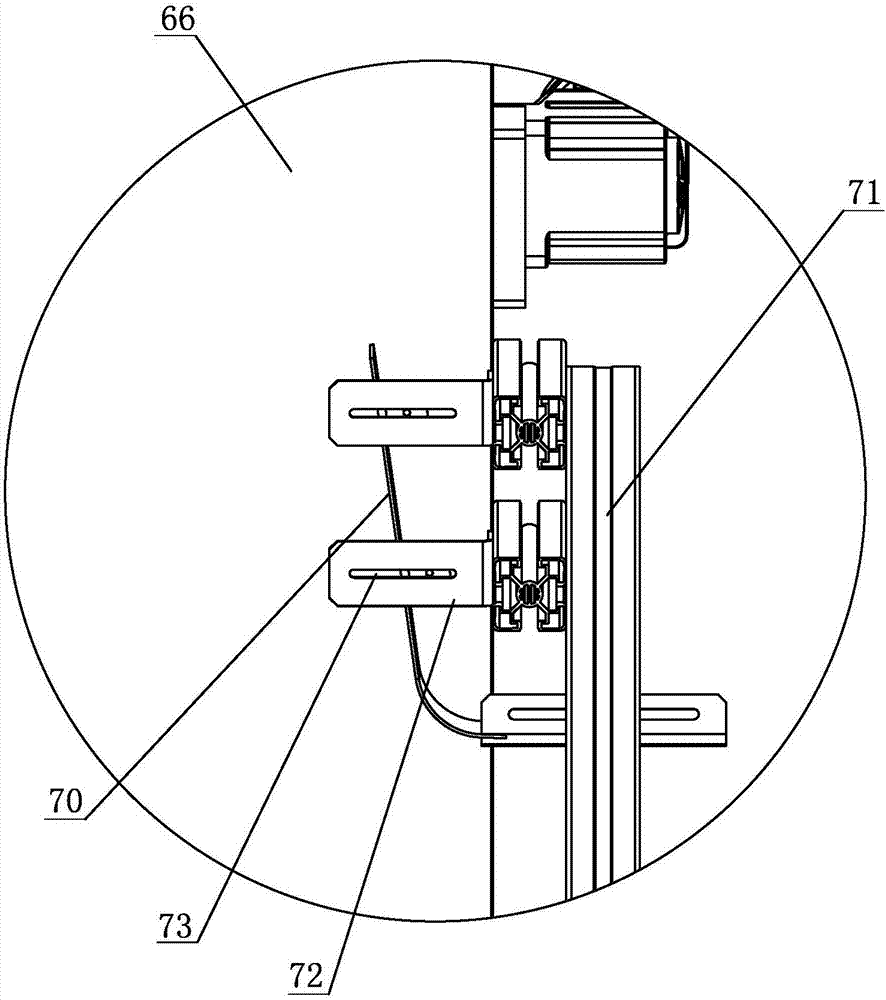

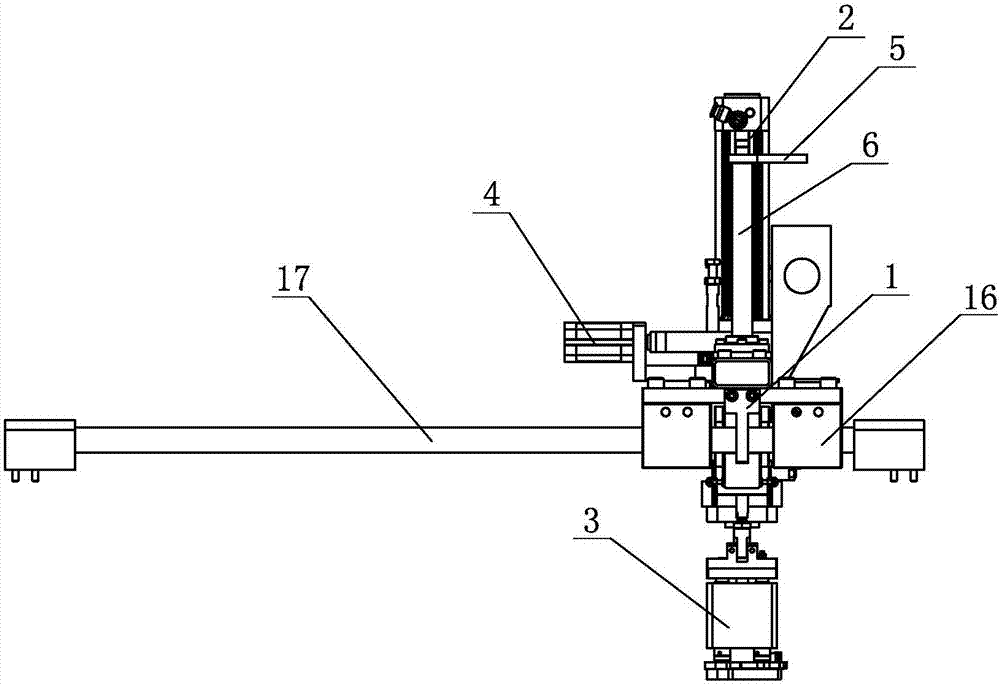

[0040] Embodiment one: see Figure 1-11 As shown, a connection line includes a first connection line 61 and a second connection line 62, the first connection line 61 is set between the sander 63 and the ablation machine 64, and the second connection line 62 is set at Between the ablation machine 64 and the spraying machine 65; the first connection line 61 and the second connection line 62 respectively include a plurality of end-to-end conveyor belts 66, and each conveyor belt 66 is vertically arranged; the first The connecting line 61 and the ablation machine 64 are connected by a first grasping and stripping device 67, and the second connecting line 62 and the ablation machine 64 are connected by a second grasping and stripping device. Material device 68, and the junction of the second connection line 62 and the sprayer 65 is provided with a multi-station inclined feeding device 69; the junction of the adjacent conveyor belt 66 is also provided with a guide device, Described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com