Double-slotted self-locking nut

A self-locking nut and nut body technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of inconvenient disassembly, increased workload, and inconvenient control, and achieve excellent results, simple installation, and tight meshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The double slotted self-locking nut of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

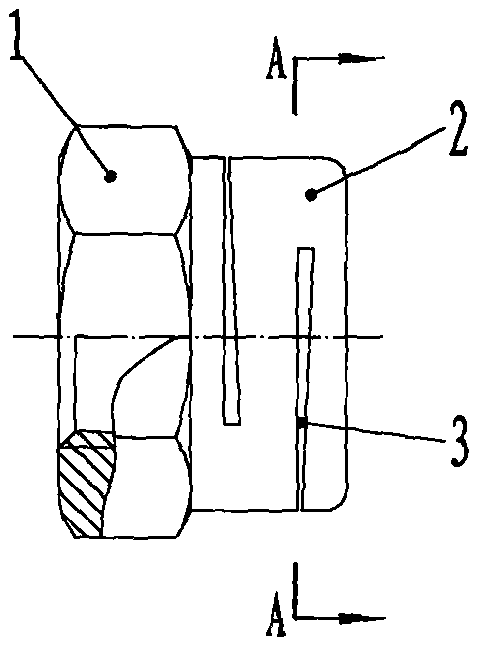

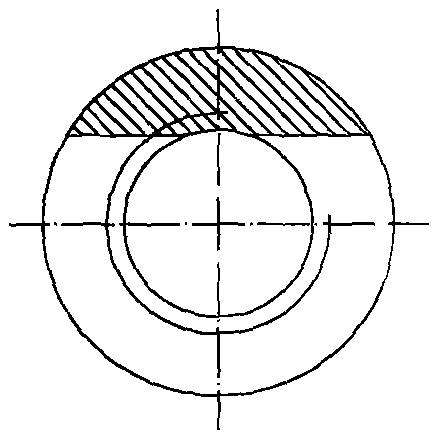

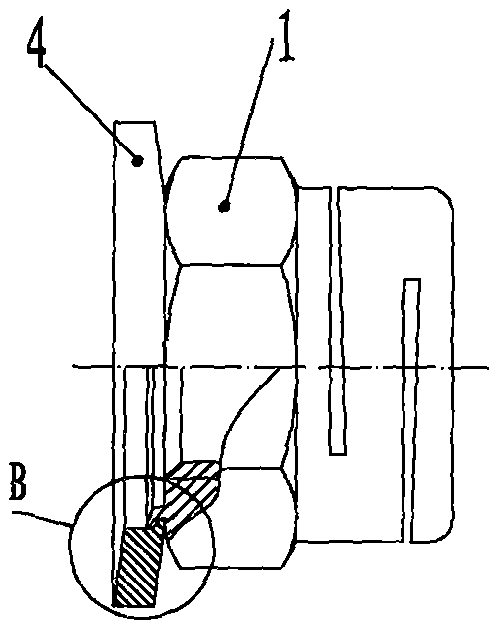

[0021] figure 1 It is a structural schematic diagram of a double-grooved self-locking nut of the present invention, figure 2 yes figure 1 A-A cross-sectional view, in the figure, the double-slotted self-locking nut includes a nut body 1, and a protruding columnar body 2 is provided on a right end surface of the nut body 1, and the columnar body 2 is provided with a screw thread communicating with the nut body 1. The threaded hole of the cylindrical body 2 is provided with a groove 3 perpendicular to the axis of the cylindrical body, and the depth of the groove 3 exceeds the semicircle of the cylindrical body. There are two grooves 3 which are symmetrical on the upper and lower sides of the columnar body 2 , the two grooves 3 are staggered left and right along the axis of the columnar body 2 , and the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com