Steel wire rope with high bearing capacity for lifting and preparation method thereof

A steel wire rope, high load bearing technology, applied in the rope field, can solve the problems of insufficient bearing capacity, frequent use of point contact wire rope, line contact wire rope, inability to undertake lifting tasks, etc., to improve the anti-extrusion ability and high bearing capacity. , The effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

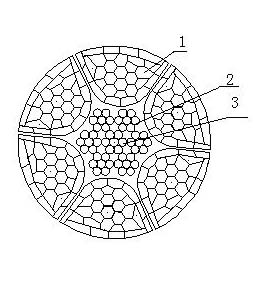

[0022] like Figure 1-Figure 5 As shown, a high load-bearing steel wire rope for hoisting is formed by twisting six outer strands 1 symmetrically wrapped around a metal core, and the metal core includes a twisted metal core central strand 3 and a metal core outer strand 2. The outer layer strand 1 is a compacted strand of the Silu-Valenton composite structure, and the outer layer strand 2 of the metal core and the central strand 3 of the metal core are point contact structures.

[0023] The outer layer strand 1 is a compacted strand formed by twisting a central steel wire with 30 steel wires of 3 different diameters in total, and is in the form of a Siru-Walington composite structure.

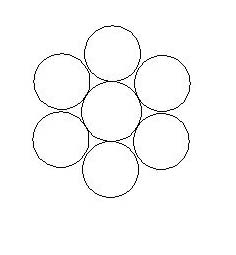

[0024] The outer strands 2 of the metal core and the central strand 3 of the metal core are twisted by 6 steel wires wrapped around one central steel wire, and are in a point contact structure.

[0025] Its preparation method is:

[0026] On the stranding car, the steel wires are arranged thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com