Falling weight deflectometer

A deflectometer and drop weight technology, which is applied in the fields of instruments, scientific instruments, and on-site foundation soil surveys, etc., can solve the problems of the cumulative duration reducing the overall survey efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

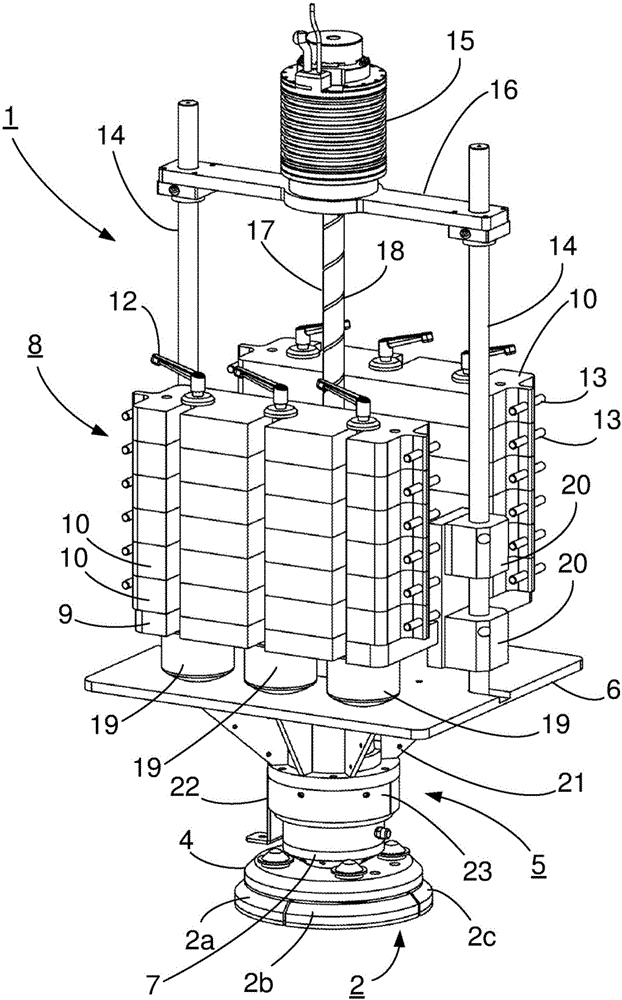

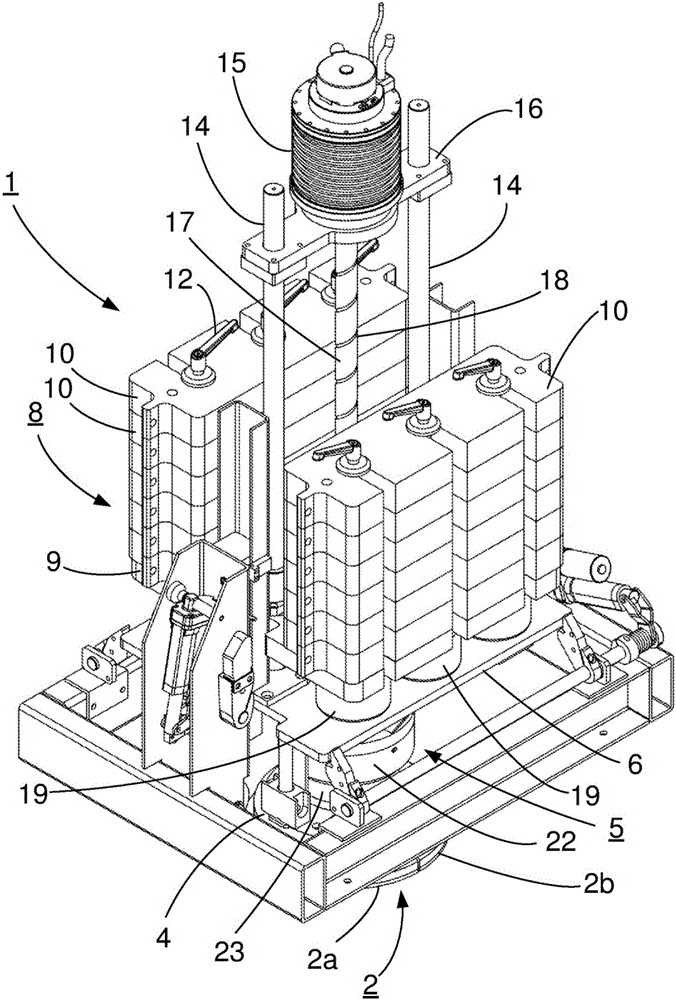

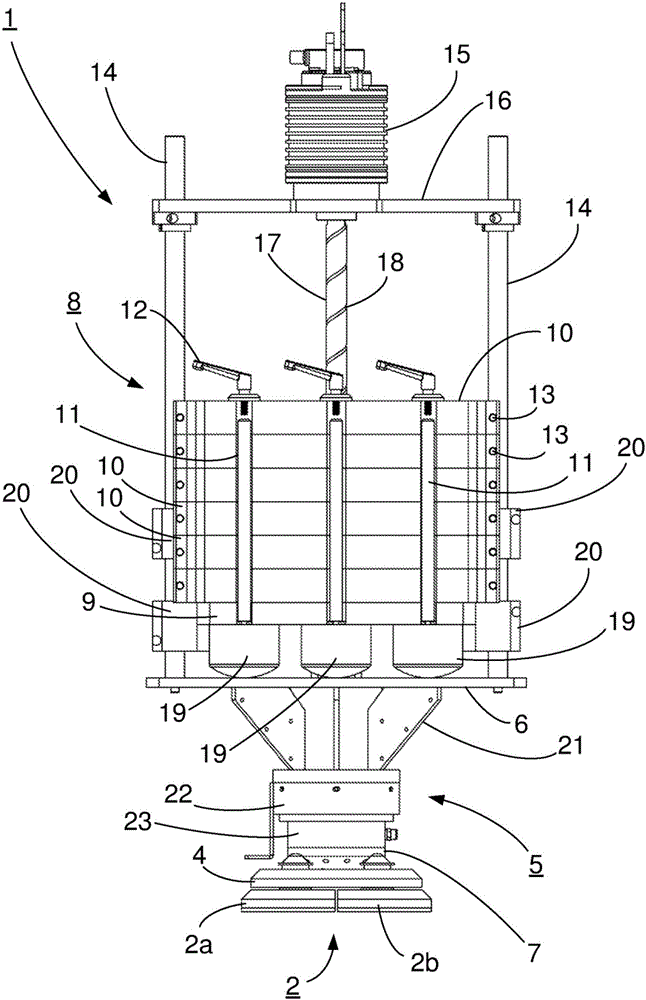

[0024] First refer to figure 1 , shows a perspective view of the core part of the falling weight deflectometer 1 according to the present invention. For the sake of mobility, in practice the falling weight deflection gauge 1 is mounted on a site known per se and at Figure 6a-Figure 6f on a suitable means of transport, such as a trailer or vehicle, as shown schematically in Reference is also made to the various descriptions in the above-mentioned article "Faldloddetshistorie", which is hereby incorporated by reference.

[0025] The falling weight deflectometer 1 comprises a falling weight 8 adapted to fall onto a load transfer plate 6 and impact the load transfer plate 6 from which the impact is transmitted via force transfer means to a test surface 30 (only in Figure 6a-Figure 6f ), such as for example a road surface of Portland cement concrete or asphalt concrete, the force transfer device comprises inter alia a support column 5 and a loading plate 2 adapted to engage wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com