Reusable imitation glass syringe

A technology for syringes and syringe barrels, which is applied in the direction of syringes, veterinary instruments, infusion sets, etc., and can solve the problems of injecting liquid medicine containing air into animals and affecting the correct observation of the injection volume of the liquid medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

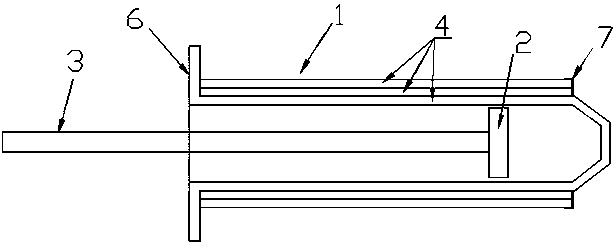

[0039] Reusable imitation glass syringes such as figure 1 As shown, it includes a syringe barrel 1, a piston 2 and a core rod 3 made of a resin material containing 4-methyl-1-pentene polymer; the piston 2 is installed at the front end of the core rod 3 and is driven by the core rod 3 Move in the syringe barrel 1; the resin material layer 4 of the 4-methyl-1-pentene polymer is made from the following raw materials in parts by weight:

[0040] Homopolymer of 4-methyl-1-pentene 97 parts

[0041] Polylactic acid 25 parts

[0042] Acetyl tributyl citrate 10 parts

[0043] 7 copies of POE.

[0044]The homopolymer of 4-methyl-1-pentene is catalyzed by a Ziegler-Natta catalyst or a metallocene catalyst to form a block, mixed with the other three components above, and then extruded and granulated. The homopolymer of 4-methyl-1-pentene has an intrinsic viscosity [η] measured at 135°C in a decalin solvent, which is in the range of 0.01dl / g or more and less than 0.50dl / g and satisfies...

Embodiment 2

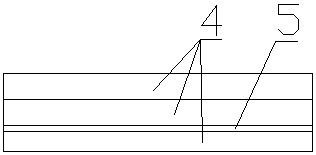

[0046] Such as Figure 6 to Figure 8 As shown, the syringe barrel 1 is composed of two layers of 4-methyl-1-pentene polymer resin material layers 4, and the outermost 4-methyl-1-pentene polymer resin material layer 4 (its composition and preparation method are the same as those in Example 1), the number 5 is hot stamped on the outer surface, and the resin material layer 4 of the outermost layer of 4-methyl-1-pentene polymer is hollow, and the inner layer is A magnetized black iron needle 9, which can slide in the hollow space 10 of the resin material layer 4 of the outermost 4-methyl-1-pentene polymer; the piston 2 is fixed with Block magnet 11, magnet 11 places the below of black iron needle 9 vertical direction on the space. The roller 12 made of the resin material of 4-methyl-1-pentene polymer is set below the iron needle 9, so that the iron needle 9 can be placed on the surface of the outermost 4-methyl-1-pentene polymer. The resin material layer 4 rolls in the hollow sp...

Embodiment 3

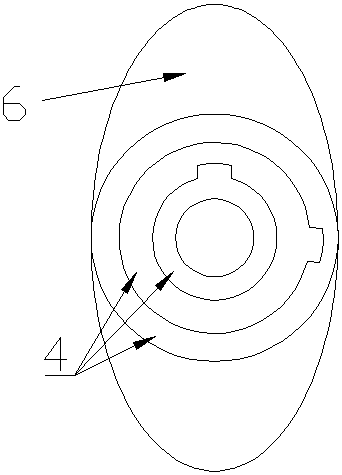

[0048] Such as Figure 9 to Figure 14 As shown, the innermost 4-methyl-1-pentene polymer resin material layer 4 in contact with the piston 2 (its composition and preparation method are the same as in Example 1) has hot stamping number 5 on the surface ,same figure 2 , the innermost 4-methyl-1-pentene polymer resin material layer 4 is provided with a locking part 13 that prevents the core rod 3 and the piston 2 from further retreating, and the locking part 13 is located at the end of the number mark 5 Directly below a digital mark; directly above the resin material layer 4 of at least two layers of 4-methyl-1-pentene polymers where the digital mark 5 is located, there is an additional layer of 4-methyl-1-pentene The polymer-like resin material layer 4, its end is fixed on the outermost 4-methyl-1-pentene polymer resin material layer 4 of the aforementioned at least two layers, which is close to the cone shape, and the additional The other end of the resin material layer 4 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com