A gluing head with gluing nozzle rotation

A technology of gluing head and gluing nozzle, which is applied in the field of gluing head, can solve the problems such as the problem that the gluing nozzle cannot be rotated, and achieve the effect of reducing equipment cost, saving cost and expanding the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

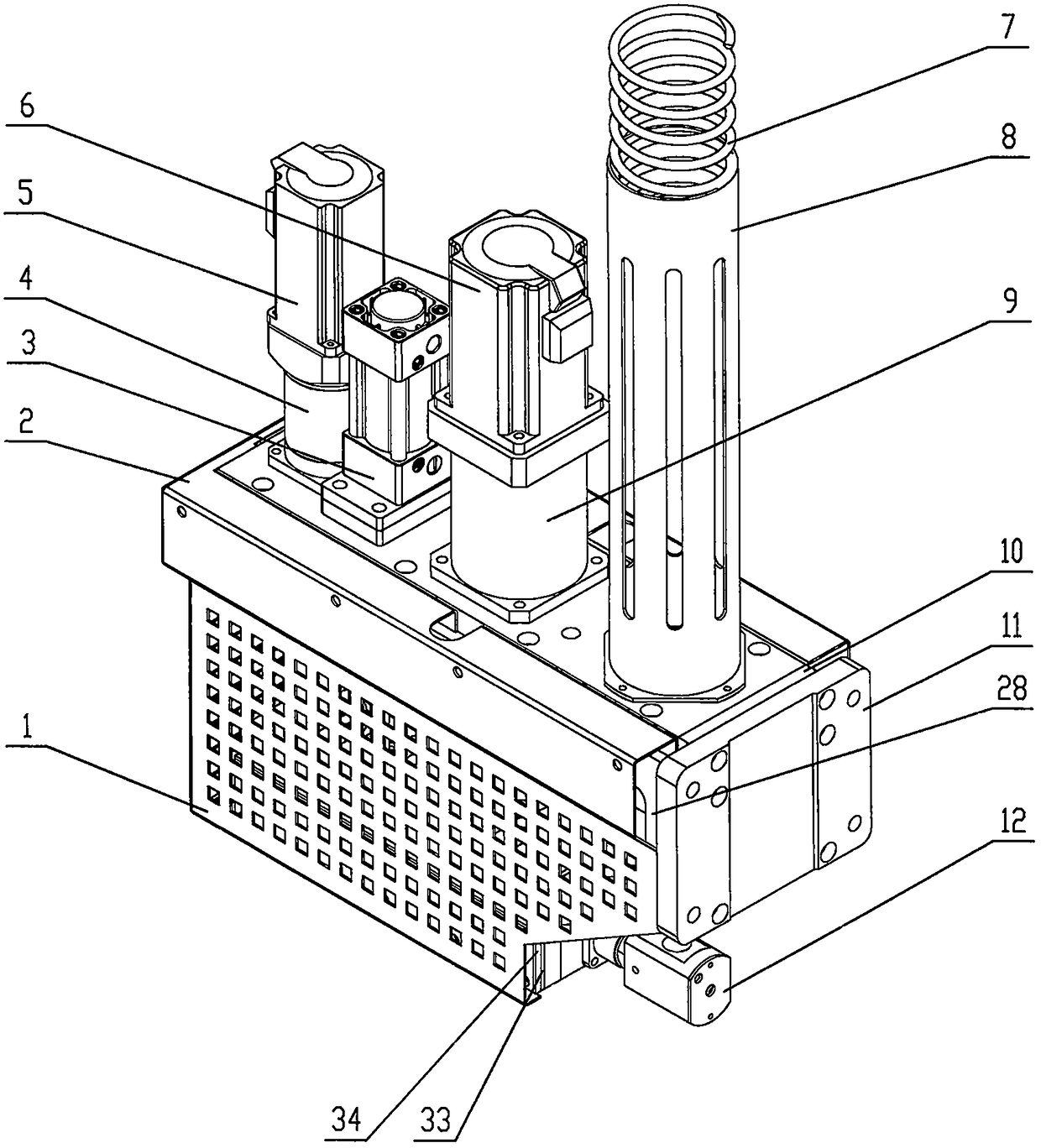

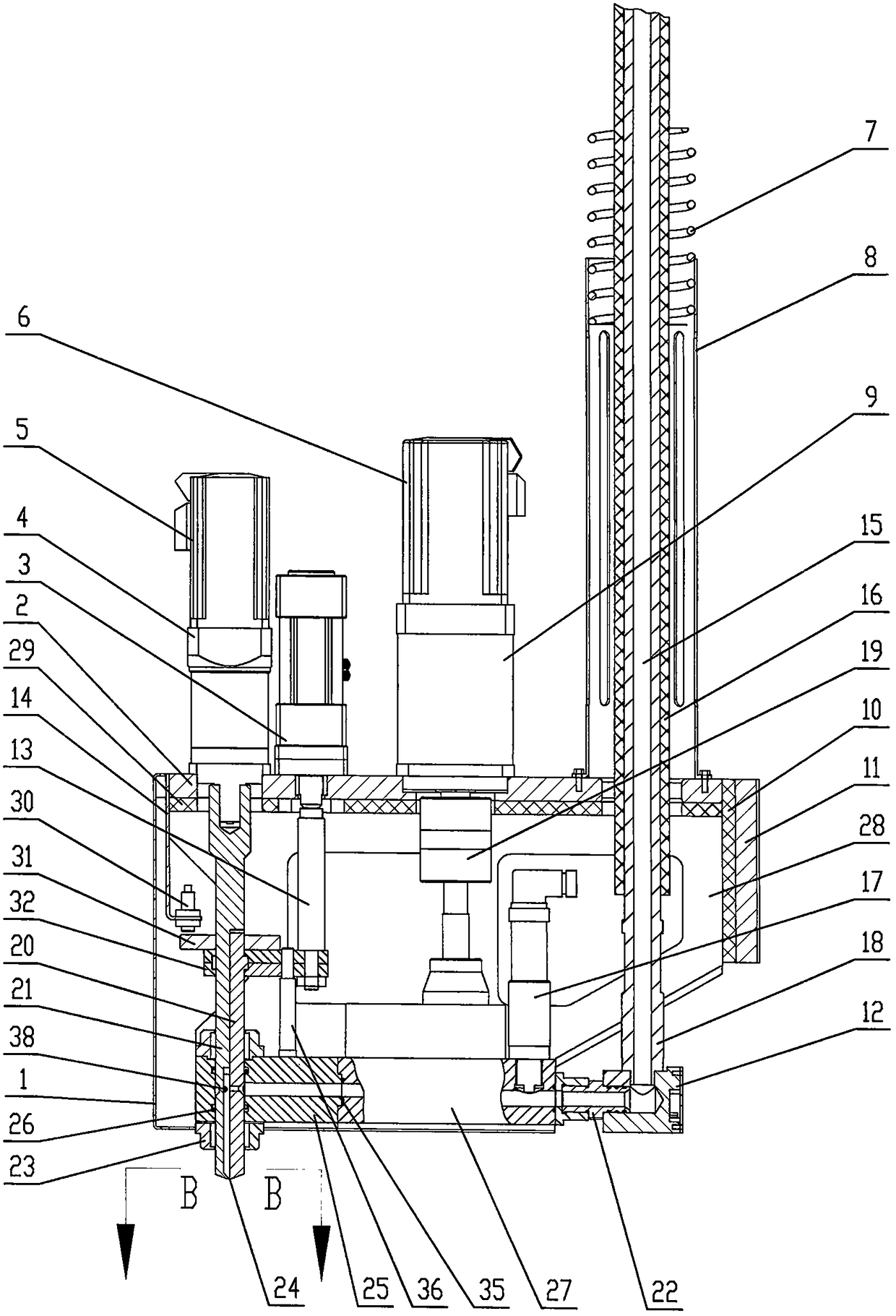

[0023] Embodiment 1: as Figure 1~3 Shown, further illustrate the present invention below in conjunction with accompanying drawing. A gluing head with a gluing nozzle rotating, used for gluing single-component glue, characterized in that it includes a gluing nozzle rotating mechanism, a gluing nozzle opening and closing mechanism, a glue supply metering device, a glue supply conveying device, the above mechanism and The device is fixed on the frame composed of the fixed plate 2, the heat shield B29, the heat shield A10, the fixed seat 11, and the bracket plate 28, the fixed seat 11 is connected with the gluing machine, and the shield 1 is installed on the above frame; the heat shield B29, heat shield A10 effectively protects heat transfer to reducer A4, reducer B9, and cylinder 3;

[0024] The nozzle rotation mechanism includes motor A5, reducer A4, nozzle A20, nozzle B21, transition body 25, guide seat 23, sealing ring A26, motor A5, reducer A4, nozzle B21 are fixedly connec...

Embodiment 2

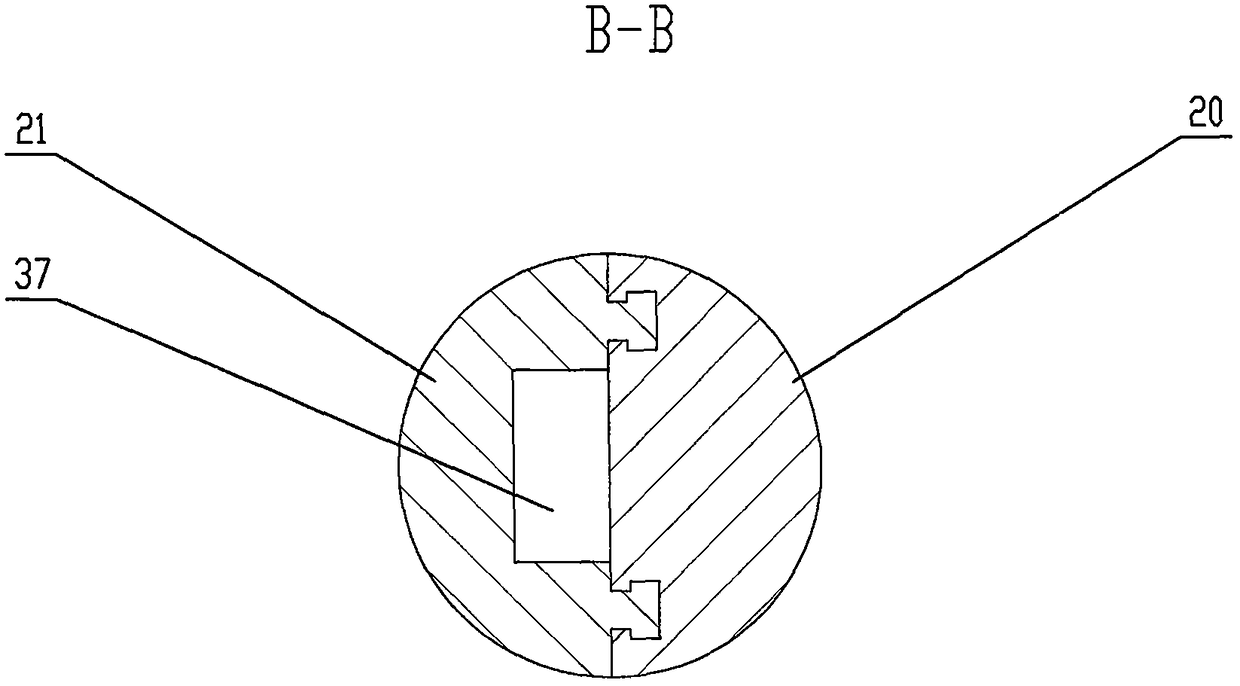

[0037] Embodiment 2 is different from Embodiment 1 in that the channel 37 cross-section of the glue nozzle 24 of the glue applicator is square or circular or elliptical or a combination of the above shapes, suitable for coating tracks that are flat or curved, and glue strips The cross-sectional shape is a square, an oval with a flat bottom, or a steamed bun-shaped workpiece.

[0038] working principle

[0039] A glue applicator with rotating glue nozzle includes a glue nozzle rotation mechanism, a glue nozzle opening and closing mechanism, a glue supply metering device, and a glue supply conveying device. The single-component glue enters the glue inlet channel of the glue hose assembly through the glue supply pump, The gear pump delivers to the glue inlet, when the lower end of the glue nozzle is opened, the one-component glue flows out; the rotation of the motor A and the reducer A drives the glue nozzle to rotate intermittently or continuously, which solves the problem of un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com