Internal cooling device of tubular thin film production equipment

A technology of production equipment and cooling device, applied in the field of tubular film production equipment, can solve the problems of inability to meet production requirements, uneven film thickness, uneven film thickness, etc., and achieve the effect of eliminating heat conduction, improving cooling efficiency, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

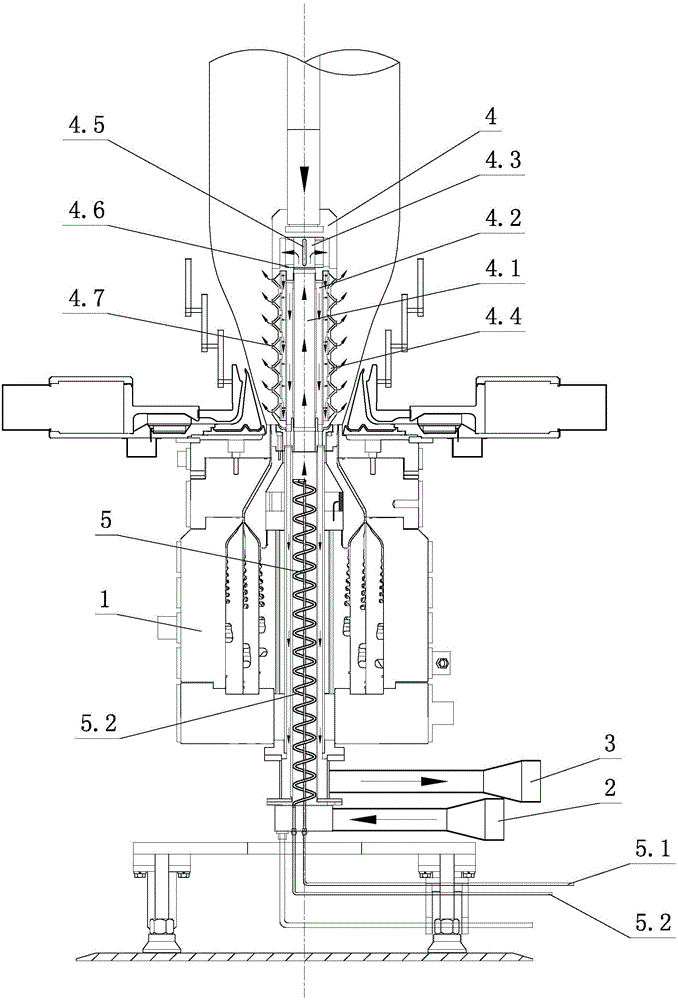

[0016] see figure 1 , the internal cooling device of the tubular film production equipment includes a mold 1 and a cold air inlet pipe 2 and a hot air exhaust pipe 3 arranged inside the mold 1, and also includes a cold and hot air reversing element 4 and a chilled water pipe 5; wherein, the cold air The air inlet pipe 2 is set inside the hot air exhaust pipe 3, the hot air exhaust pipe 3 is arranged inside the mold 1, the hot and cold air reversing element 4 is arranged on the mold 1, and is connected with the cold air inlet pipe 2 and the hot air exhaust pipe respectively. The pipes 3 communicate with each other to realize cold air intake through the inner pipe and hot air exhaust through the outer pipe; the chilled water pipe 5 is spirally arranged inside the cold air inlet pipe 2 .

[0017] Specifically, the chilled water pipe 5 is made of brass, wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap