A rotary table type linear vacuum packaging machine

A vacuum packaging machine, turntable technology, applied in vacuum/special atmosphere for packaging, packaging, transportation packaging, etc., can solve problems affecting production efficiency, reduce vacuum device layout, reduce resource utilization, etc., to improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

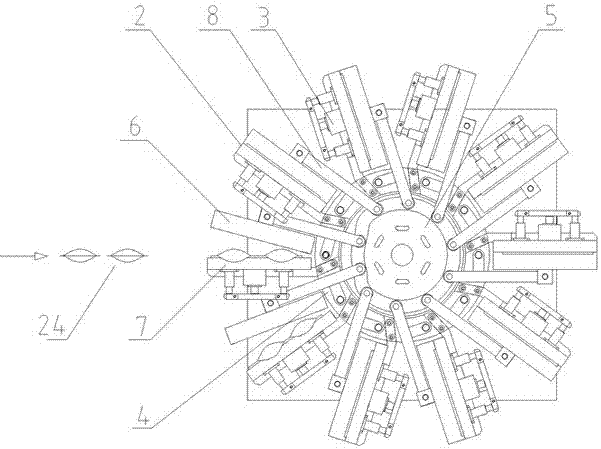

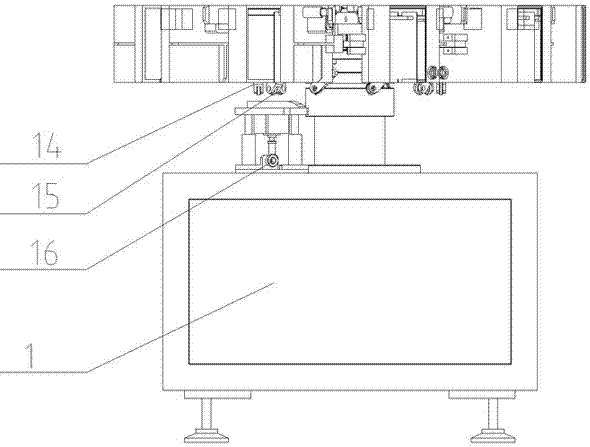

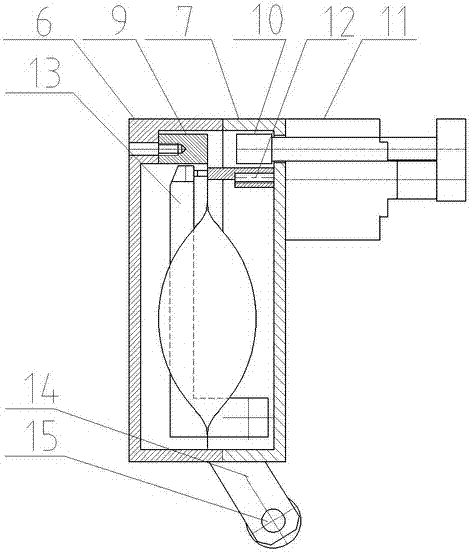

[0027] Embodiment 1. When the present invention is in use, the power supply controls the rotation of the turntable 4, and when the vacuum device 2 is close to the bag delivery outlet station of the bag delivery device, the swing rod 8 is controlled by the cam 5 to swing, and the swing seal cover 6 is opened. The arc-shaped backing plate 18 below the vacuum mechanism acts on the swing arm roller 15 along with the lifting cylinder 16 to drive the collision, so that the swing arm 14 swings around the hinge point and then drives the swing fixed bag block 13 to overcome the tension spring force and open to a certain extent. Then when it is at the bag delivery outlet station, the packaging bag is placed in a straight line and sent into the bag opening of the vacuum device 2 by the linear transition device, and then the arc-shaped backing plate 18 resets with the lifting cylinder 16, When the turntable 4 continued to rotate and left the bag delivery outlet station, the swing arm rolle...

Embodiment 2

[0028]Embodiment 2. When the present invention is in use, the power supply controls the turntable 4 to rotate, and when the vacuum device 2 is close to the bag delivery outlet station of the bag delivery device, the swing rod 8 is controlled by the cam 5 to swing, and the swing sealing cover 6 is opened. During the station, the clamping rod 19 is driven by the air rod to collide with the swing arm roller 15, so that the swing arm 14 swings around the hinge point and then drives the swinging bag fixing block 13 to overcome the force of the tension spring and open a certain clamping bag mouth. Afterwards, the packaging bag is placed in a straight line and sent into the bag opening of the vacuum device 2 by the linear transition device, then the clamping rod 19 resets with the cylinder, and when the turntable 4 continues to rotate to leave the bag delivery station, the swing arm The roller 15 breaks away from the effect of the arc-shaped backing plate 18, the swing arm 14 swings b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com