A kind of method of alkyne selective hydrogenation

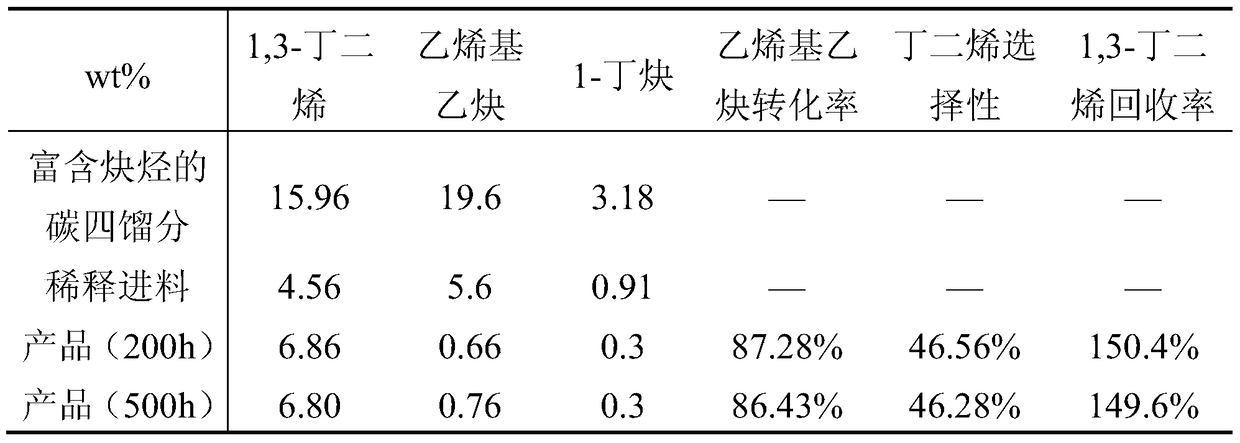

A selective and alkyne-based technology, applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrogenation to hydrocarbons, etc., can solve the problems of high product circulation ratio, low liquid space velocity, etc., to improve thermal stability , Improve the acid properties, increase the output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

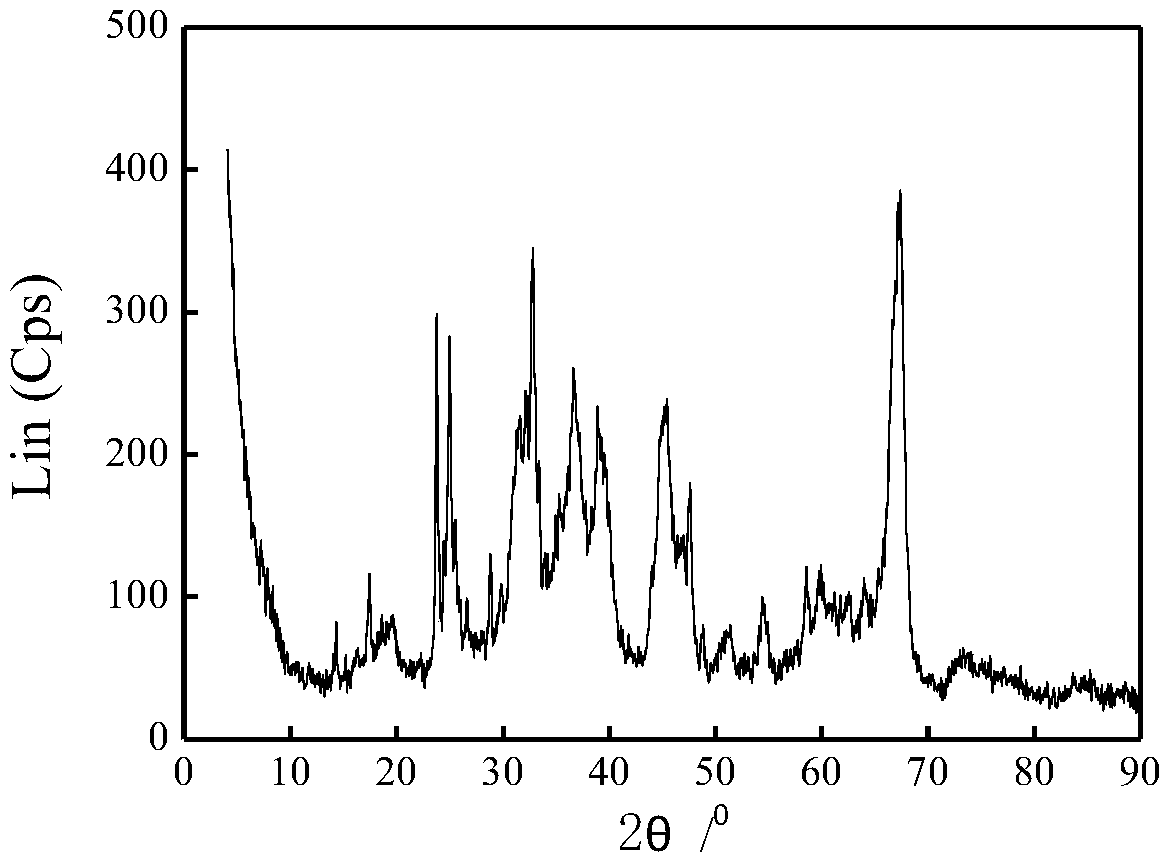

Image

Examples

Embodiment 1

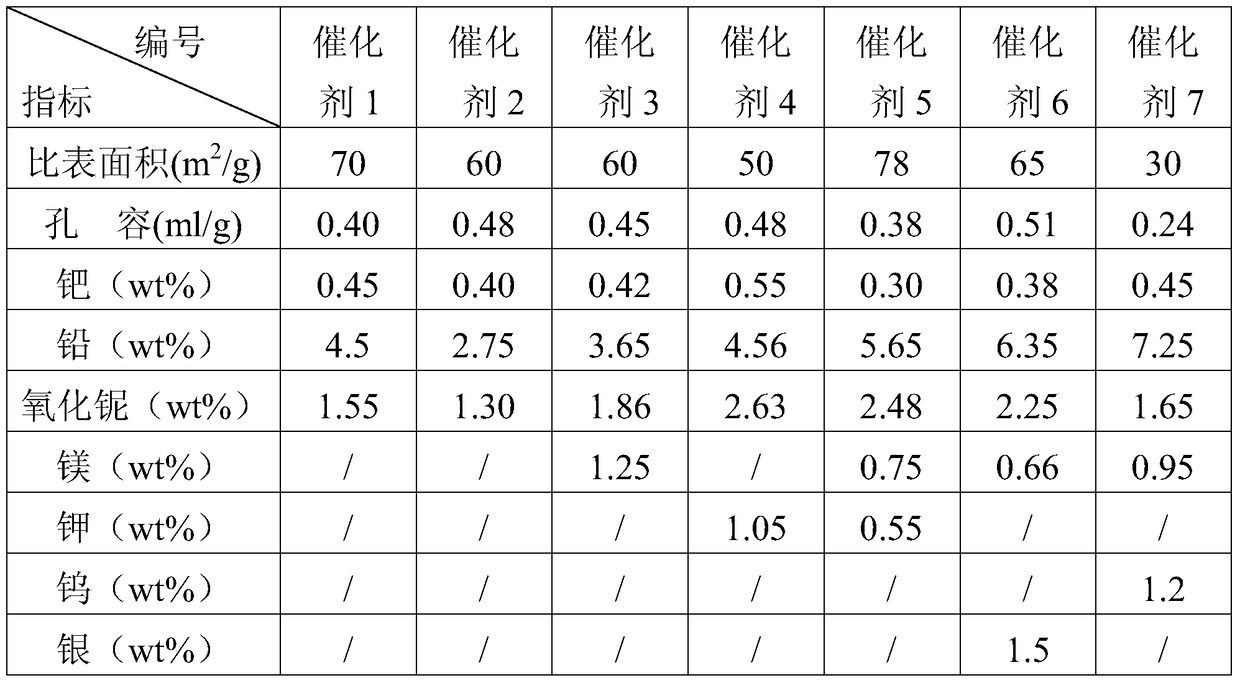

[0062] The C4 fraction rich in alkynes is diluted with the C4 raffinate, and the weight ratio of the C4 fraction rich in alkynes to the C4 raffinate is 1:2.5. The adiabatic reactor adopts a single-stage adiabatic bubbling bed, and uses catalyst 1, and the catalyst is reduced at 120°C for 6 hours under a hydrogen atmosphere. Reaction temperature 50℃, reaction pressure 1.2MPa, liquid space velocity 8.5h -1 , the molar ratio of hydrogen to alkyne is 1.5, Table 2 is the composition of materials before and after the reaction.

[0063] Table 2 Composition of materials before and after reaction

[0064]

Embodiment 2

[0066] The C4 fraction rich in alkynes is diluted with the C4 raffinate, and the weight ratio of the C4 fraction rich in alkynes to the C4 raffinate is 1:3. The adiabatic reactor adopts a single-stage adiabatic bubbling bed, adopts catalyst 2, and the catalyst is reduced at 120°C for 6 hours under a hydrogen atmosphere. The reaction temperature is 45°C, the reaction pressure is 1.5MPa, and the liquid space velocity is 9.0h -1 , the molar ratio of hydrogen to alkyne is 1.5, Table 3 is the composition of materials before and after the reaction.

[0067] Table 3 Composition of materials before and after reaction

[0068]

Embodiment 3

[0070] Dilute the alkyne-rich C4 fraction with the raffinate C4, the weight ratio of the alkyne-rich C4 fraction to the raffinate C4 is 1:3, and the adiabatic reactor adopts a single-stage adiabatic bubbling bed, Catalyst 3 was used, and the catalyst was reduced at 120° C. for 6 h under hydrogen atmosphere. The reaction temperature is 45°C, the reaction pressure is 2.0MPa, and the liquid space velocity is 10.0h -1 , the molar ratio of hydrogen to alkyne is 2.0, Table 4 is the composition of materials before and after the reaction.

[0071] Table 4 Composition of materials before and after reaction

[0072]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com