A method for improving photochromic response speed and color body time of Rhodamine

A technology of response speed and photochromic materials, which is applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of application limitations, short existence time of ring-opening bodies, etc., achieve fast response speed, simple preparation method, and large application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation of photochromic materials that improve rhodamine photochromic response speed and color body time:

[0031] The rhodamine photochromic material system combined with polyurethane varnish coating has a structure of a physical blend of polyurethane varnish and rhodamine derivatives, wherein the polyurethane varnish is a single component.

[0032] The preparation method of the photochromic material is:

[0033] Dissolve 8-15 mg of rhodamine derivatives into 10-15 mL of xylene solvent, and sonicate until it is completely dissolved.

[0034] Then dilute 0.1-1 mL of one-component polyurethane varnish with 10-15 mL of xylene solvent, and ultrasonically until it is completely dispersed.

[0035] Then add the xylene solution of the rhodamine derivative dropwise into the xylene solution of the polyurethane varnish coating, and stir at a high speed until the mixture is uniform.

[0036] Then spread the mixed solution evenly on the glass sheet, and dry it in a vacuum...

Embodiment 2

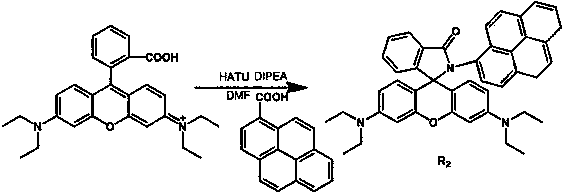

[0040] The present embodiment synthesizes rhodamine derivative R 2

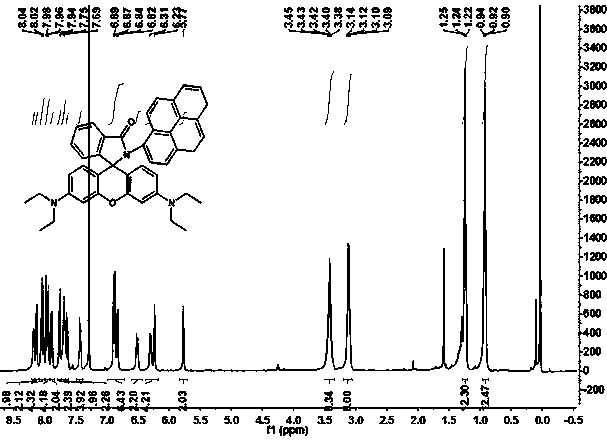

[0041]Dissolve 0.78 mmol of 1-pyrenecarboxylic acid, 1.55 mmol of HATU, and 0.51 mL of DIPEA in 10 mL of DMF solvent. After reacting for 30 minutes, add 1 mmol of rhodamine B to react for 10 hours. After the reaction, use a vacuum pump to remove the solvent, add 10-100 mL of deionized water to obtain a precipitate, use ethyl acetate: n-hexane = 1:1 as eluent, and use column chromatography to obtain a pink solid R 2 , that is, the small molecule of the rhodamine derivative. 1 H NMR (400 MHz, CDCl 3 ) δ8.18 (d, J = 7.5 Hz, 2H), 8.08 – 8.00 (m, 2H), 7.99 – 7.92 (m, 4H), 7.88 (d, J = 8.2 Hz, 4H), 7.76 (d, J = 9.3 Hz, 2H), 7.69 (t, J = 5.5 Hz, 2H), 7.64 (d, J = 9.3 Hz, 4H), 7.43 (d, J = 7.4 Hz, 2H), 6.86 (dd, J = 20.1 , 8.7 Hz, 2H),6.51 (d, J = 7.7 Hz, 6H), 6.30 (d, J = 8.5 Hz, 2H), 6.23 (s, 4H), 5.77 (s,2H), 3.42 (dt, J = 13.7, 7.0 Hz, 8H), 3.11 (q, J = 6.8 Hz, 8H), 1.24 (t, J =6.9 Hz, 12H), 0.92 (t, J = 6.9...

Embodiment 3

[0043] Photochromic effect test:

[0044] According to the method of Example 1, dissolve the rhodamine R2 of Example 2 and the polyurethane varnish in xylene, mix them uniformly by ultrasonic physics, spread it on a glass sheet, dry the xylene solvent in a vacuum oven at 70°C to form a film, and record it as sample S 1 ;Similarly, we use Rhodamine R2 in Example 2 to spread on the glass sheet separately, and dry the xylene solvent in a vacuum oven at 70°C to form a film, which is recorded as sample S 2 . We did photochromic experiments on samples S1 and S2 respectively. We placed both the S1 and S2 in a dark box above a moderate intensity UV lamp that emits UV light at a wavelength of 365nm. The S1 sample showed obvious photochromic phenomenon in 2 minutes, the apparent color changed from light yellow to pink, and the fluorescence also changed from blue-green to orange-red. In contrast, no obvious photochromic phenomenon was found in S2 under 1 hour of light. So we say that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com