Bidirectional telescoping type horizontal-rotation cable telescoping device

A technology of horizontal rotation and telescopic devices, which is applied in the installation of cables, the arrangement of cables between relatively moving parts, and electrical components, etc., which can solve the problems of inconvenient repair and maintenance, no cable telescopic devices, cable fatigue, etc., and achieve good mechanics Performance and processability, reduced overheating sensitivity, enhanced strength and toughness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

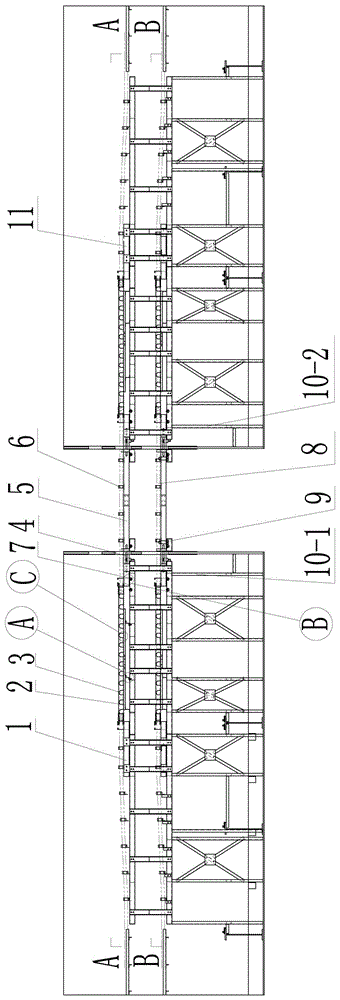

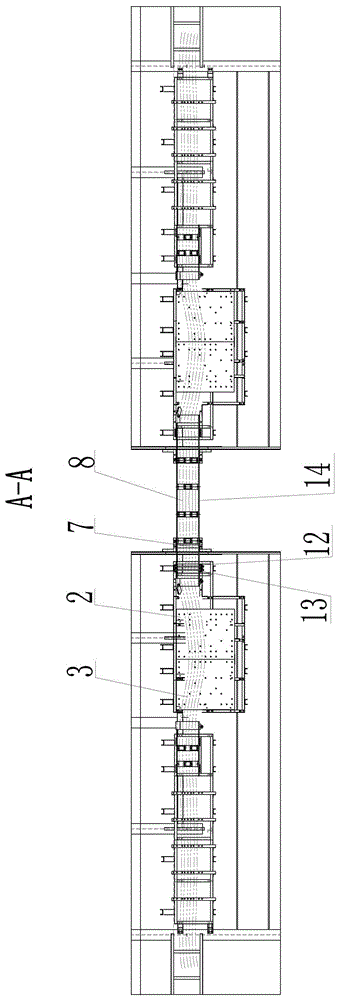

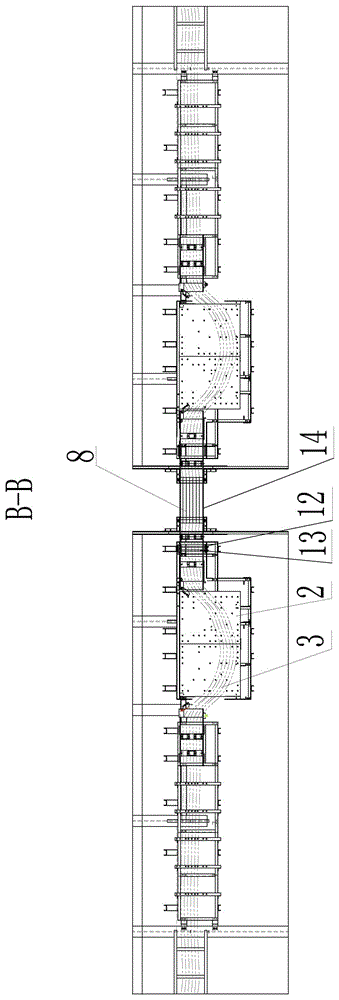

[0042] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0043] Such as Figure 1-6 As shown, the horizontally rotating cable telescopic device of the present invention is mainly composed of telescopic chains arranged on the bridge box girder, and is characterized in that the telescopic chains include head telescopic joints arranged on the bridge box girder I, arranged on The tail expansion joint on the bridge box girder II, the connection mechanism 5 arranged between the head expansion joint and the tail expansion joint, and the cable limiting device provided on the connection mechanism 5, each expansion joint includes a bridge box The fixed bracket 10 connected to the bottom plate is placed horizontally above the fixed bracket 10 and the fully sealed sliding platform 2 fixedly connected with the fixed bracket 10 is arranged above the fully sealed sliding platform 2 and connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com