Gutter inlet garbage filtering and circulating system convenient to replace

A technology of circulation system and gullies, which is applied to waterway systems, water supply devices, drainage structures, etc., can solve problems such as serious water accumulation on roads, accumulation and blockage of underground drainage pipes, and reduced flow rate and channel of drainage pipes, etc., to achieve good filtration effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

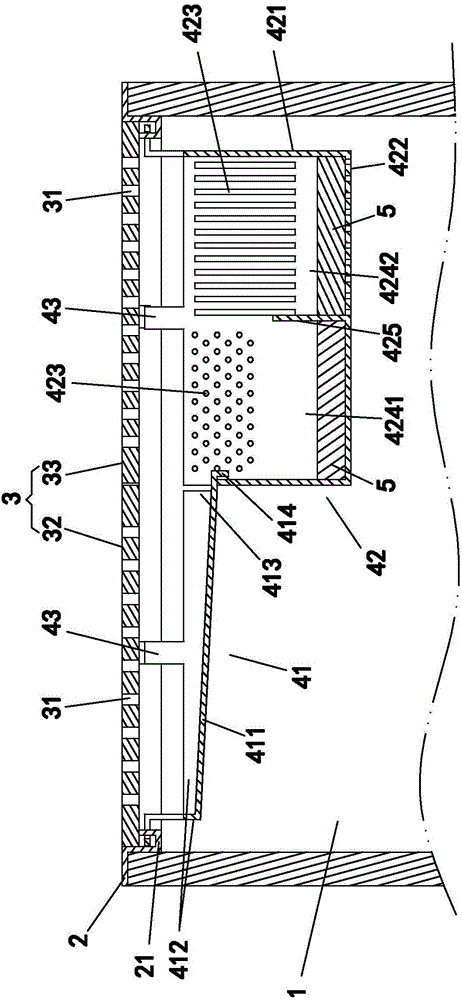

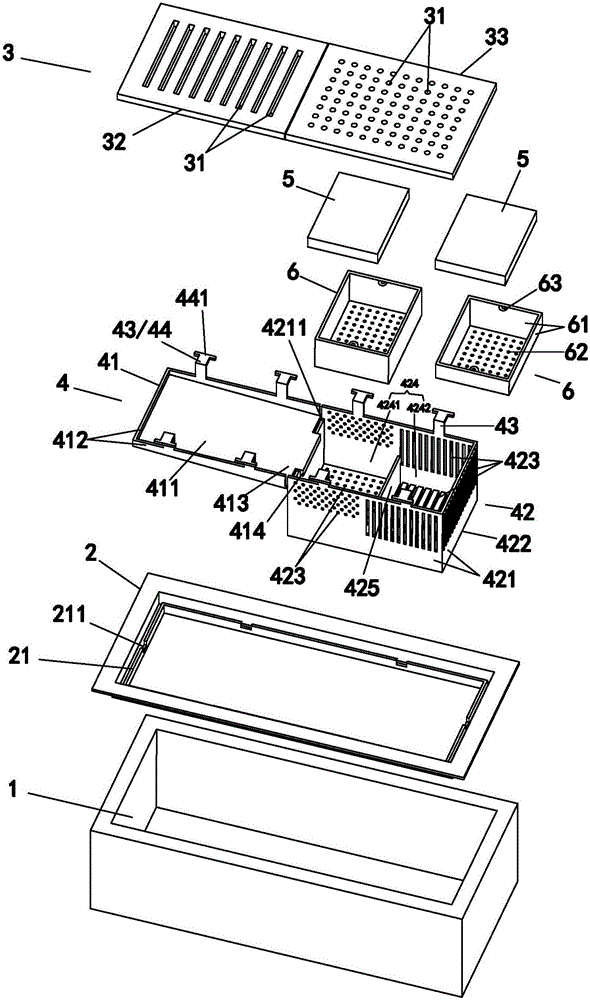

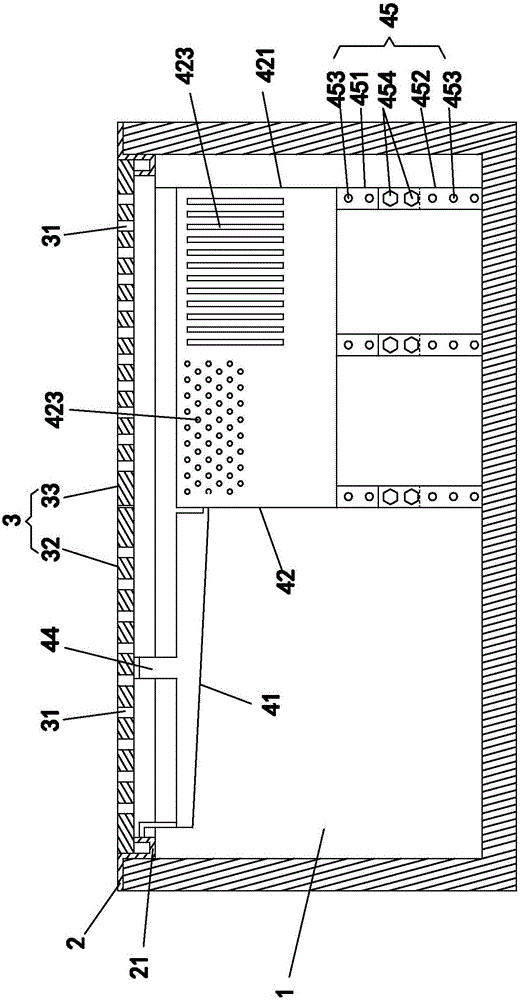

[0035] Garbage filter circulation system in gullies, such as figure 1 and figure 2As shown, it includes a drainage well 1 opened on a city road, a well cover seat 2 fixedly arranged on the wellhead of the drainage well 1, a well cover 3 embedded and covered on the well cover seat 2, and a filter device 4 arranged under the well cover 3. The drainage holes 31 provided on the well cover 3, and the filter holes 423 are provided on the filter device 4. The above-mentioned is a known structure. The difference between the present invention and the prior art is that, as shown in the figure, the filter The device 4 includes a diversion basket 41 and a filter basket 42; the upper edge of the diversion basket 41 and the filter basket 42 is spaced from the lower surface of the well cover 3, and the side wall of the dive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com