Welding-free door plate assembly

A combined, welding-free technology, used in door leaves, windows/doors, building components, etc., can solve the problems of not being able to lay out and stack well, increase transportation costs, and fail to achieve volume, etc., to reduce welding links, reduce The effect of low transportation cost and production energy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Now in conjunction with accompanying drawing, the present invention is described in detail:

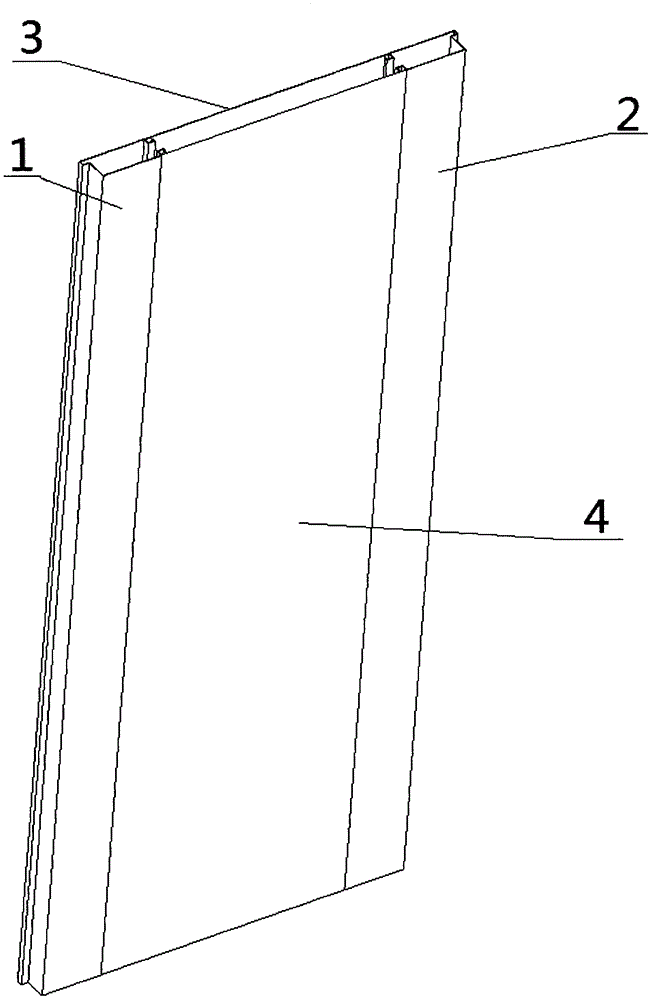

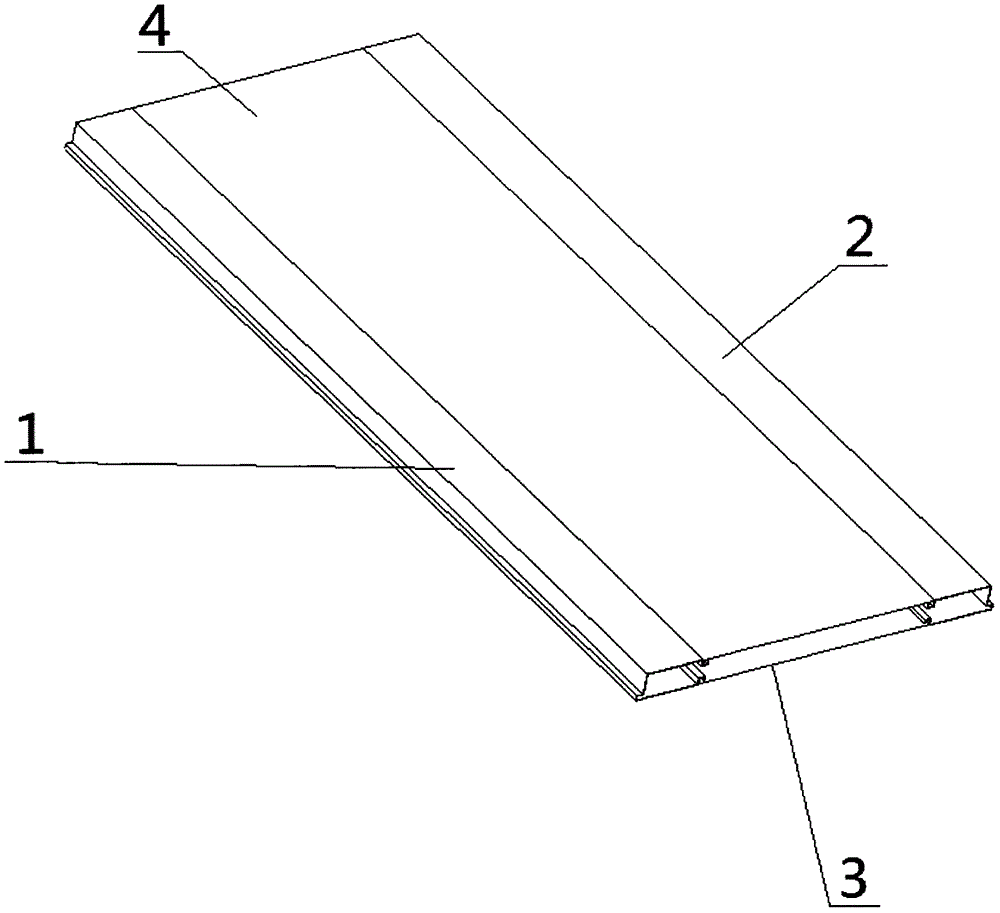

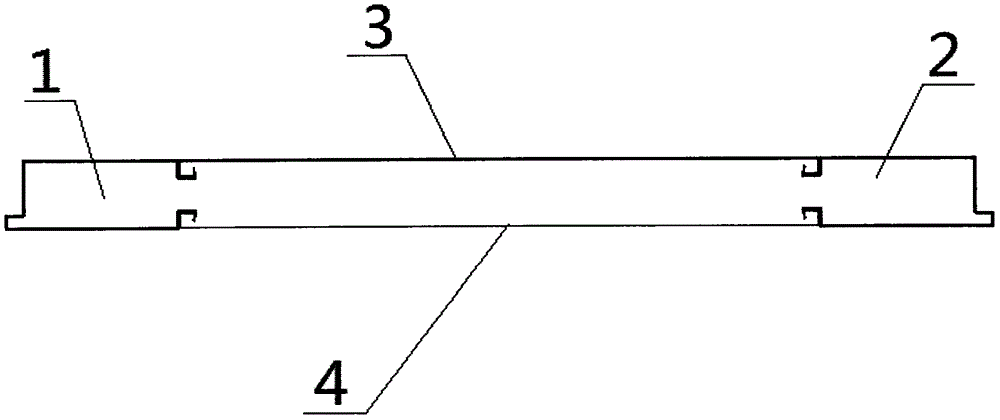

[0037] The invention is composed of a hinged door panel (1), an overlock door panel (2), a middle front panel (3), and a rear front panel (4).

[0038] figure 1 , figure 2 , image 3 Shown is the structural representation of the present invention. Wherein, 1 is a hinged door panel, 2 is a lock edge door panel, 3 is a middle front panel, and 4 is a rear front panel.

[0039] Figure 4 with Figure 5 Shown is the structure schematic diagram before combination of the present invention. Wherein, 1 is a hinged door panel, 2 is a lock edge door panel, 3 is a middle front panel, and 4 is a rear front panel.

[0040] Image 6 Shown is the structural schematic diagram of the hinged door panel (1) in the present invention. The hinge door panel (1) has a double-slot structure, a cover edge (5) is provided on the left side of the hinge door panel (1), and two upper and lower butt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com