Multifunctional container valve

A container valve, multi-functional technology, applied in the direction of valve details, valve devices, valve operation/release devices, etc., can solve the problems of large space occupied by nitrogen start-up bottles, unstable system, high cost, etc., and achieve safe and rapid start-up. Improve start-up efficiency and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

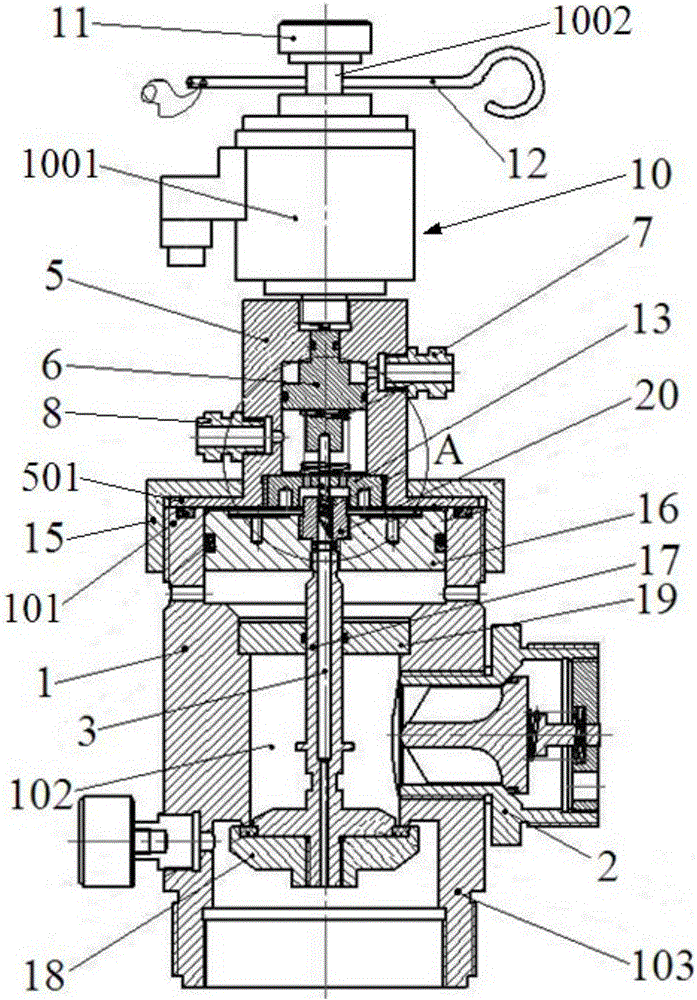

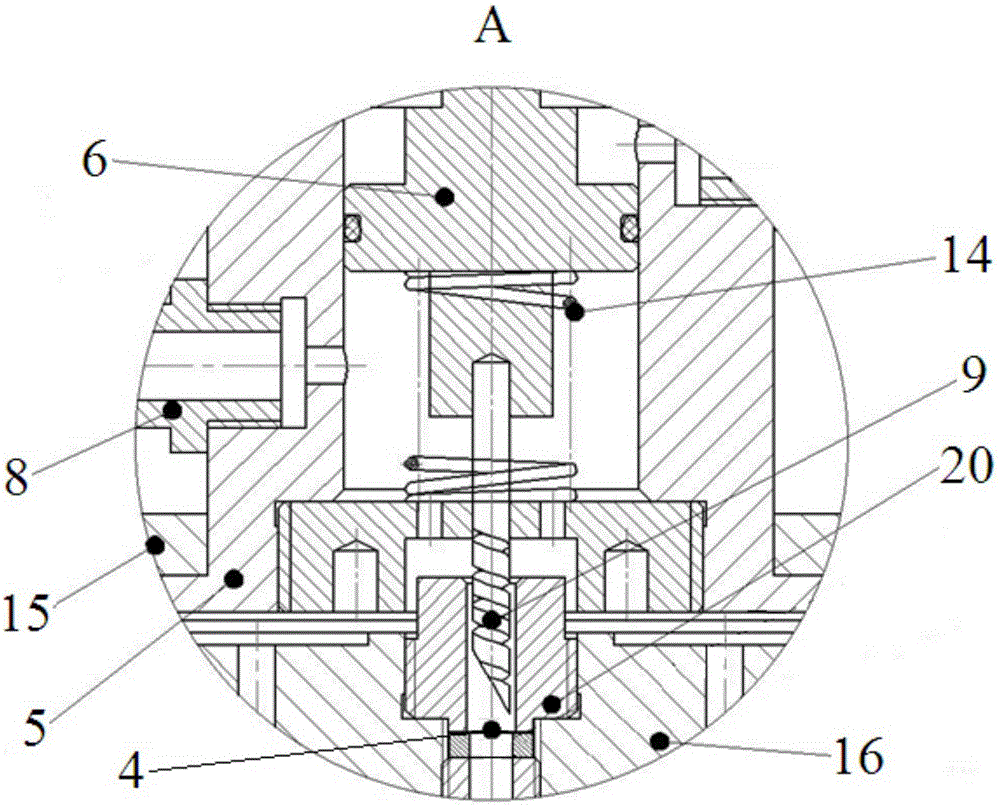

[0029] like figure 1 As shown, the embodiment of the present invention provides a multifunctional container valve, including: a main valve body 1, a main valve core assembly, a drive housing 5, a first piston 6, and a piercing needle 9. The main valve body 1 has The upper end interface 101, the valve cavity 102 and the lower end interface 103, the lower end interface 103 is connected to the fire extinguishing agent liquid storage bottle, the side wall of the main valve body 1 is provided with a header joint 2 communicating with the valve cavity 102, and the collector The pipe joint 2 is connected to the fire extinguishing agent manifold; one end of the main valve core assembly is slidingly fitted with the inner side wall of the upper end interface 101, and the other end of the main valve core assembly is blocked between the valve cavity 102 and the inner wall of the upper end interface 101. Between the lower end interfaces 103, the main valve core assembly is provided with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com