Body-in-white air-tightness detection system and detection method

A technology of air tightness detection and body-in-white, which is applied in the field of detection systems, can solve the problems of comparative analysis and technical improvement, the inability to record the leakage amount, and the inability to evaluate the sealing effect of the body-in-white, etc., achieving low cost, accurate experimental results, and guaranteed air tightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

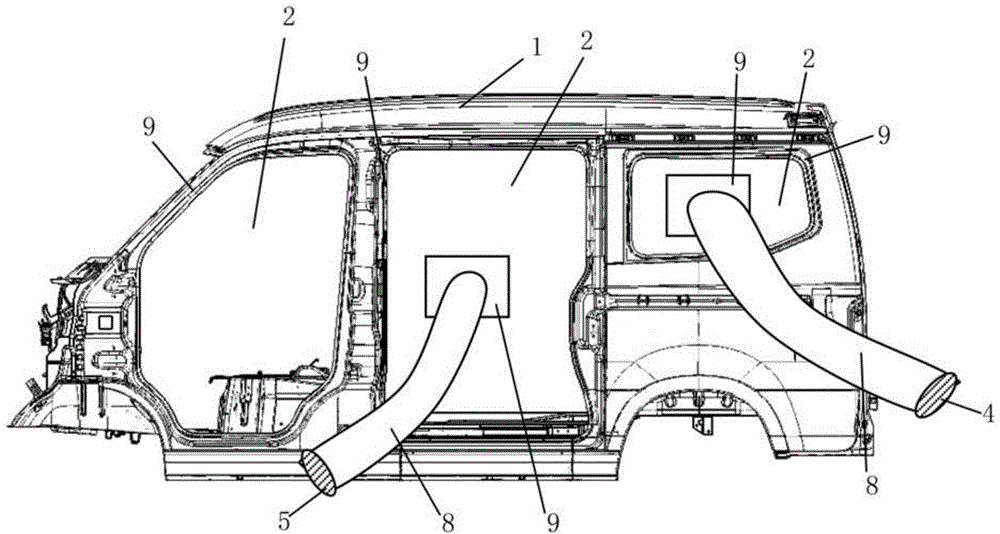

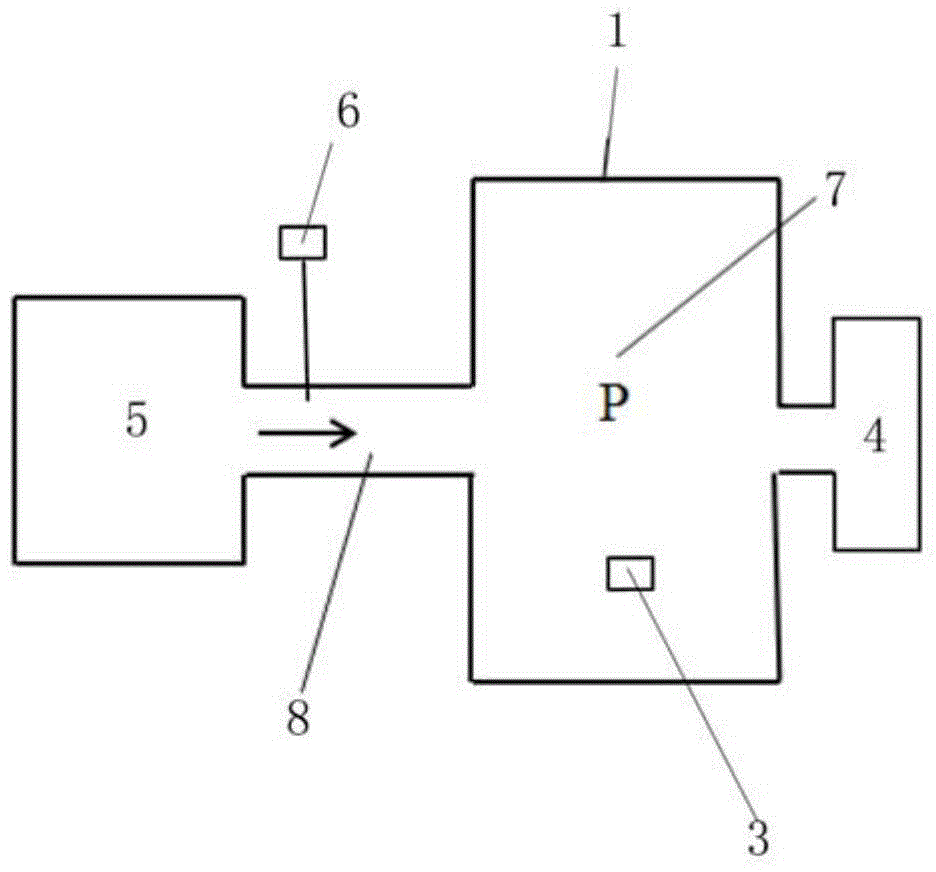

[0031] The following with attached Figure 1 to Figure 2 The body-in-white airtightness detection system and detection method of the present invention will be further described in detail.

[0032] For the body-in-white airtightness detection system of the present invention, please refer to Figure 1 to Figure 2 , comprising at least eight plexiglass plates 2, pressure sensors 3, smoke generators 4, fan 5 and air intake sensor 6, the shape and size of the plexiglass plates 2 are respectively the same as those of the glass windows on the front doors on the left and right sides of the body-in-white 1 , the upper glass windows of the rear doors on the left and right sides, the butterfly glass windows on the left and right sides, the front windshield windows and the glass windows of the rear tailgate are consistent in shape and size, and the plexiglass plate 2 is respectively connected with the upper glass of the front doors on the left and right sides of the body-in-white 1 windo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com