Bellows air tightness testing equipment and testing method

A technology for air tightness detection and bellows, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the acceleration and deceleration rate of fluid, etc., can solve the problems of low detection accuracy, no bellows, waste of water resources, etc. , to achieve the effect of high air tightness detection accuracy, novel structure and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

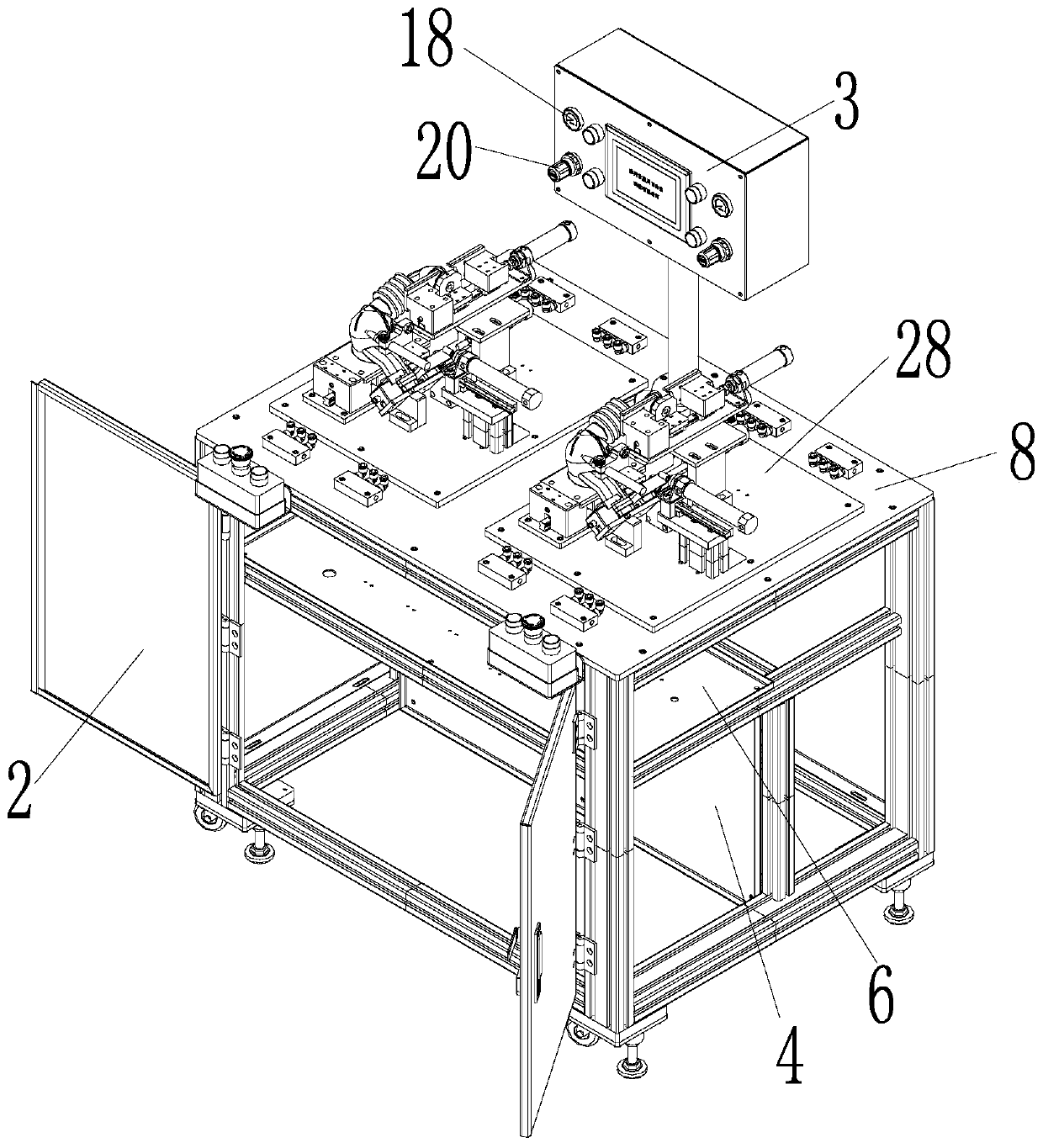

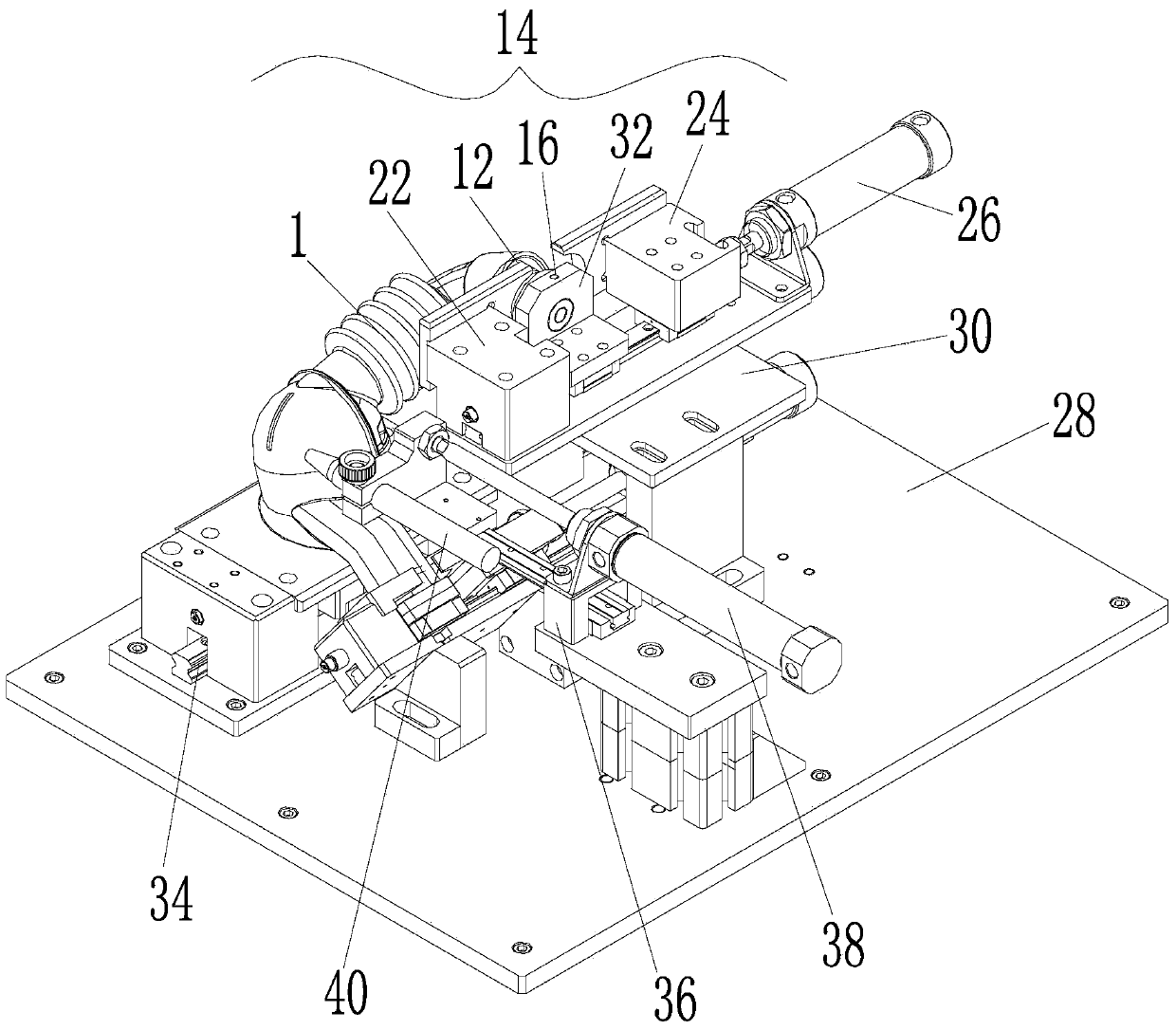

[0033] Such as figure 1 , 2As shown, this embodiment discloses a bellows airtightness testing device for testing the airtightness of two bellows, including an electrical cabinet 2, and the electrical cabinet 2 is provided with an electrical installation board 4 and an air circuit installation board 6 The top of the electrical cabinet 2 is provided with a workbench bottom plate 8, and all the electrical lines and gas pipelines of the electric console 3 detection equipment are installed on the workbench bottom plate 8 through a pillar, respectively installed on the electrical installation board 4 and the gas pipeline in the electrical cabinet 2. On the road mounting plate 6, place neatly. Several airtightness detection fixtures 10 that work independently are installed on the described workbench bottom plate 8. In order to improve efficiency, in this implementation, preferably one detection equipment is equipped with two airtightness detection fixtures 10, which can double the a...

Embodiment 2

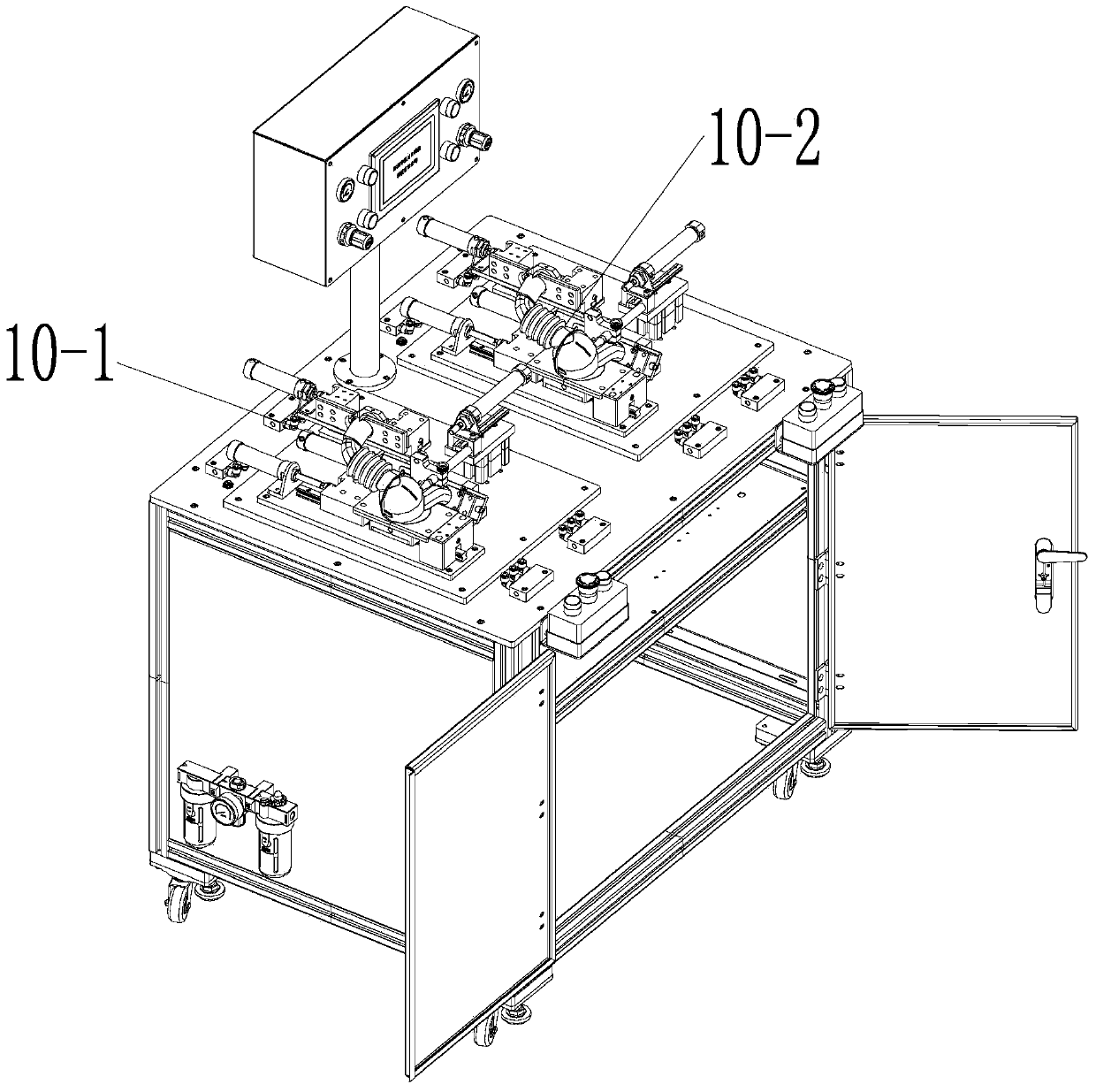

[0040] Such as image 3 , 4 As shown, this embodiment discloses a bellows airtightness detection device, which is used to cooperate with the detection of the airtightness of the three-port bellows. The difference between the detection device in the second embodiment and the detection device in the first embodiment is only that : Cooperate with the bellows for detecting three ports, three inner cavity sealing heads 12 and three outer wall seal clamping assemblies 14 are arranged on the mounting plate 28, and the three inner cavity sealing heads 12 are all fixed on the outer wall sealing clamps matched therewith On the fixed clamping part 8 of the component 14, two of the outer wall sealing clamping components 14 are fixedly arranged on the mounting plate 28, and the third outer wall sealing clamping component 14 is arranged on the On the slide rail bottom plate 30, the sliding clamping parts 10 of the two outer wall seal clamping assemblies 14 are arranged on the mounting plat...

Embodiment 3

[0043] Such as Figure 5 As shown, this embodiment discloses a detection method using the above-mentioned detection equipment to detect the airtightness of the bellows, including the following steps:

[0044] S1: Tube installation, corresponding to the number of nozzles of the bellows 1, select multiple pairs of inner cavity sealing heads 12 and outer wall sealing clamping components 14, insert the inner cavity sealing heads 12 from the nozzle of the bellows 1, and then install The bellows 1 with the lumen sealing head 12 is placed in the first jaw 42, and one side of the outer wall of the end of the bellows 1 is clamped by the first jaw 42, and the above-mentioned steps are repeated for each mouth of the bellows 1. The action completes the loading action of the bellows 1, and then safely starts the detection equipment;

[0045] S2: The nozzle is sealed and clamped, and the first cylinder 26 is controlled to start the process, so that the second clamping mouth 44 on the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com