Water tightness detection device for diaphragm gas meter

A membrane gas meter and detection device technology, which is applied to measurement devices, test/calibration devices, and liquid/vacuum degree measurement for liquid tightness, etc., can solve the problem of increasing production costs of enterprises, wasting human resources and slowing down production progress. and other problems, to achieve the effect of increasing the production cost of the enterprise, speeding up the production progress of the enterprise, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

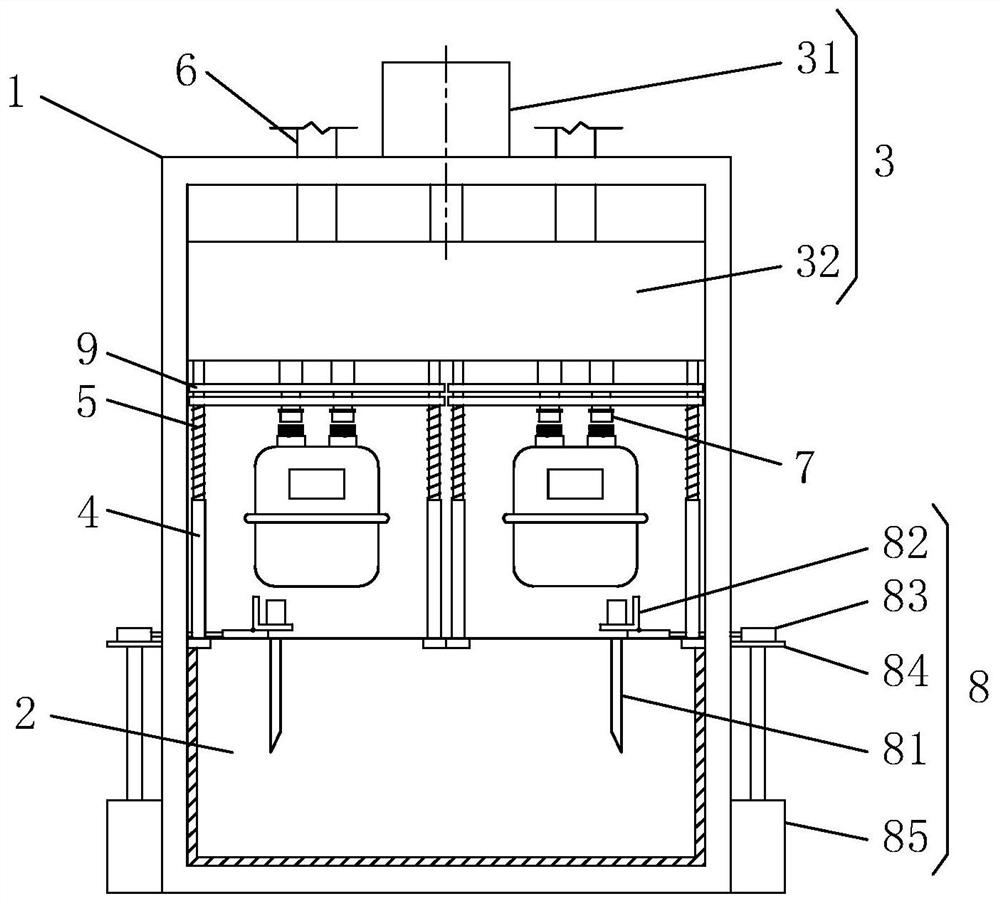

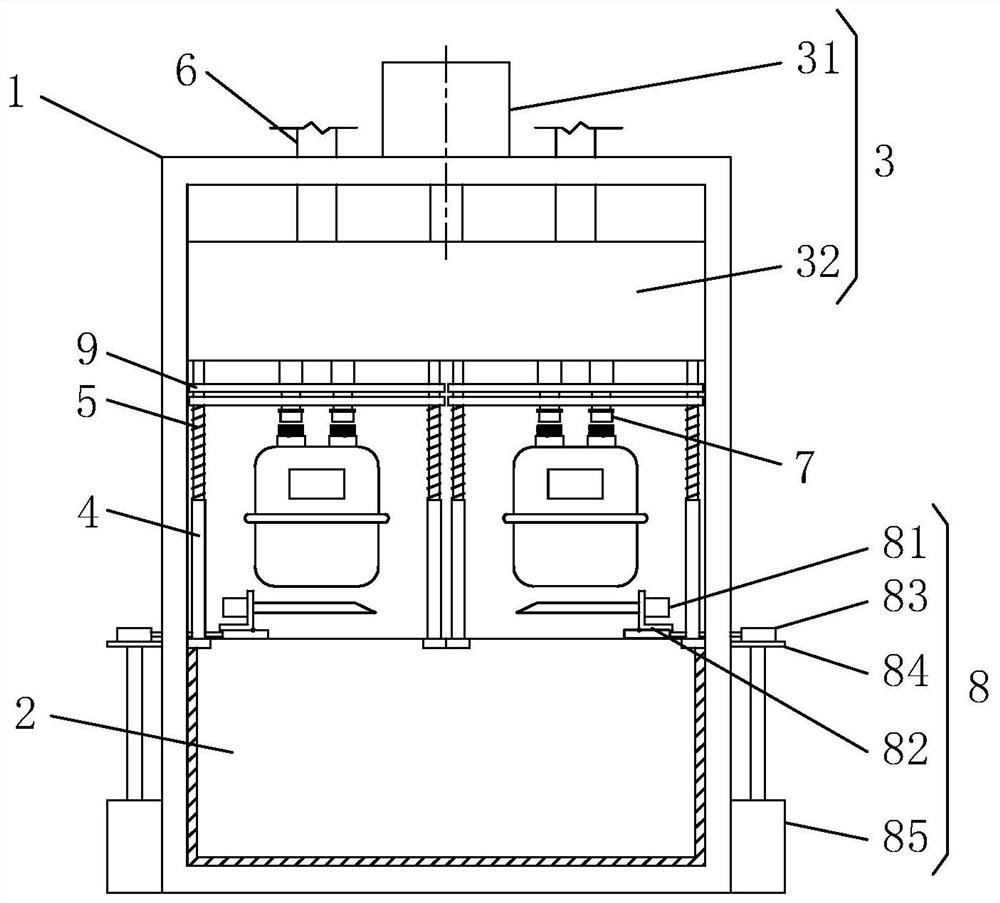

[0027] Such as figure 1 As shown, a water tightness detection device for a membrane gas meter includes a device body 1 on which a detection water tank 2 , a lifting drive 3 , a three-way air inlet pipe 6 , and an air inlet and outlet connector 7 are provided.

[0028] The air inlet and outlet connectors 7 include an inlet connector and an outlet connector, and are connected to the air supply equipment through the three-way inlet pipe 6 . The lifting driver 3 includes a lifting cylinder 31 and a lifting console 32 , and the output end of the lifting cylinder 31 is connected to the lifting console 32 . The air inlet and outlet connector 7 is installed on the lifting driver 3, specifically, the inlet and outlet air connector 7 is installed on the lifting console 32, and the detection water tank 2 is installed at the vertical lower position of the inlet and outlet connector 7. Preferably, the lifting cylinder 31 is arranged along the vertical direction of the device body 1 .

[...

Embodiment 2

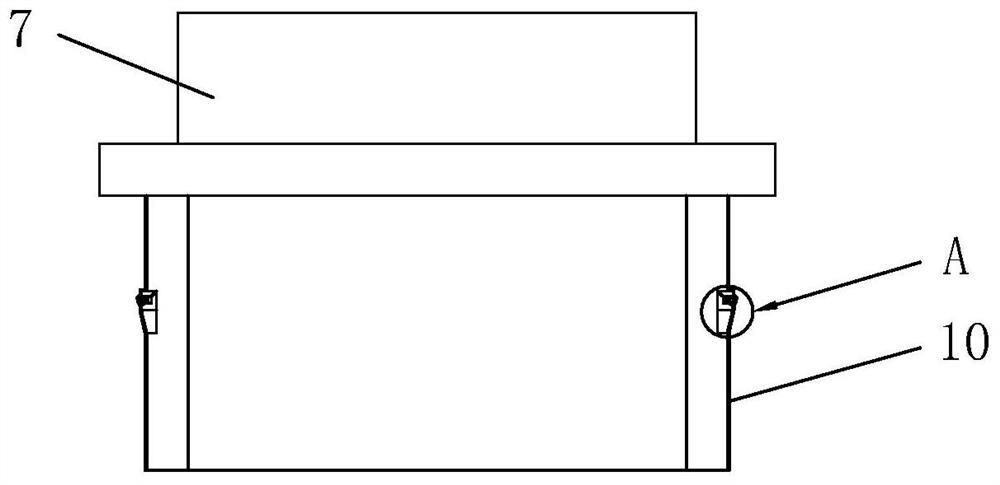

[0046] The difference between this embodiment and Embodiment 1 is that: Figure 4 As shown, the end of the moving sealing block 114 abutting against the sealing ring 10 is configured as a bevel-shaped structure, and the inclination angle of the bevel-shaped structure is equal to the inclination angle of the bevel-shaped structure on the preliminary sealing block 111 . In this way, it is also convenient for the air inlet and the air outlet of the membrane gas meter to move and abut against the movable sealing block 114, which is convenient for installation.

[0047] The specific implementation principle of the present invention is: when working, first install the air inlet and the air outlet of the membrane gas meter on the air inlet and outlet connector 7, and the lifting driver 3 drives the lifting console 32 to descend, driving the inlet and outlet gas connector 7 With the diaphragm gas meter downwards, until stretching into the water of the detection water tank 2, then vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com