Brittle material plastic deformation-fracture transformation critical depth and critical load detecting method based on nanometer cut-in instrument

A technology of plastic deformation and critical depth, which is applied in the direction of analyzing materials, instruments, measuring devices, etc., can solve the problems of poor reliability and low detection accuracy, and achieve the effect of overcoming the indentation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

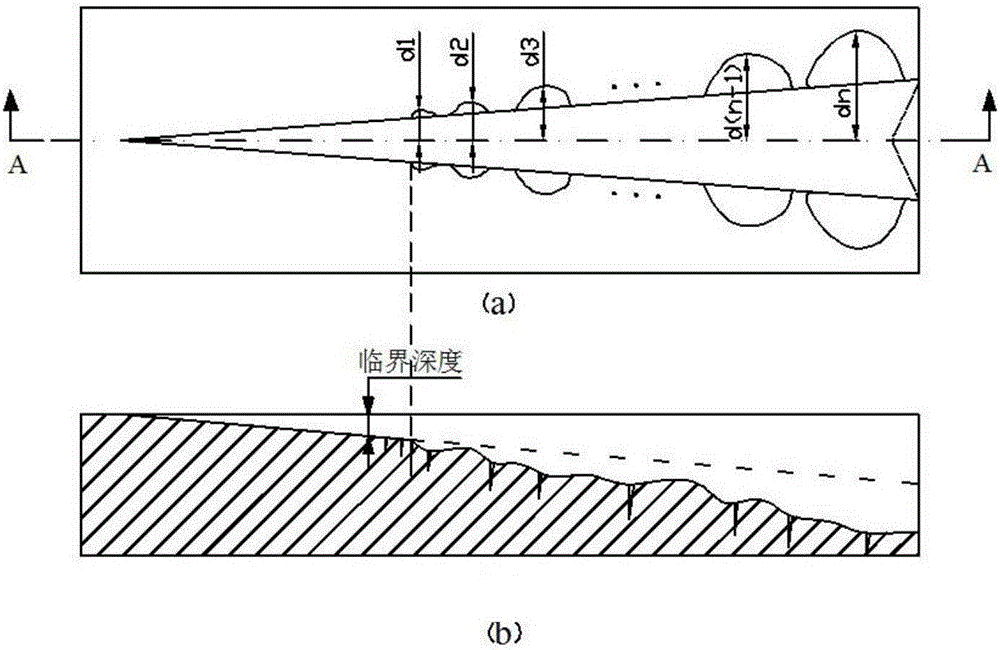

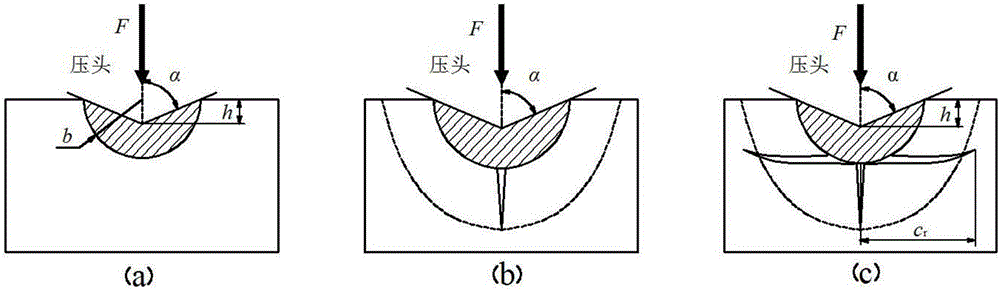

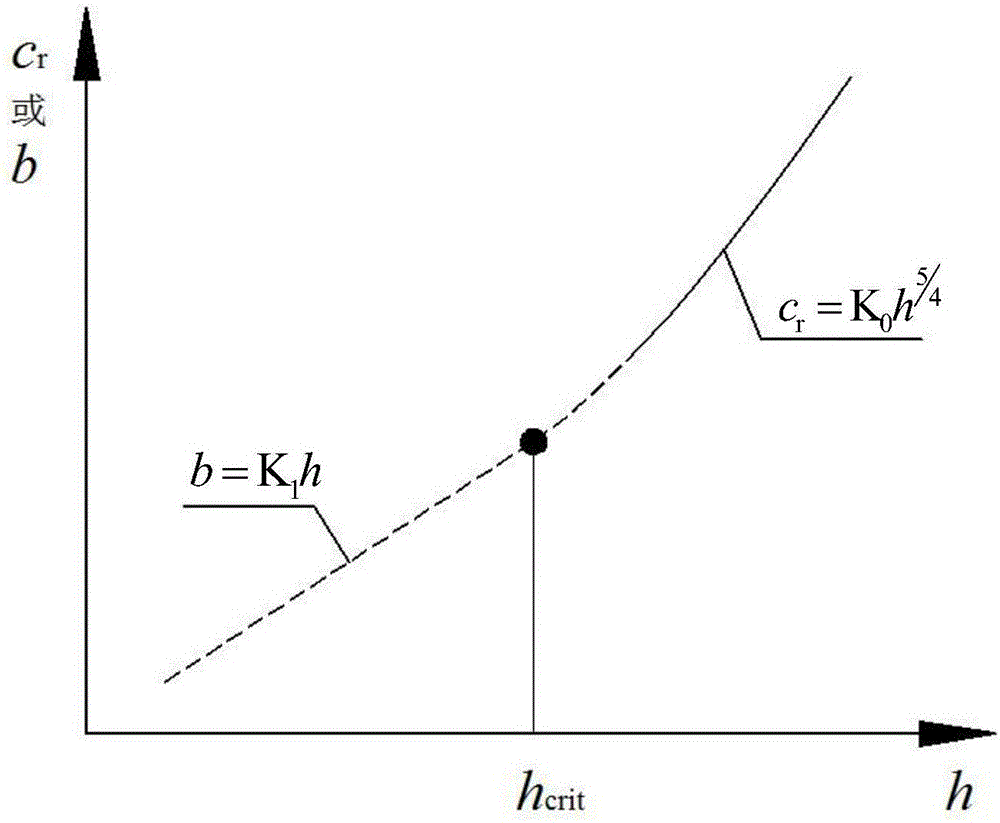

[0060] Example 1: Detection of plastic deformation-fracture transition critical depth and critical load of sapphire C-face. According to the analysis of the shape of diamond abrasive grains used in ultra-precision machining, the angle range between the facet and the center line is 46° to 82°, and its average value is close to 65.3° of the Bosch indenter; the angle between the edge and the center line is 62° to 89° , its mean value is close to that of the Bosch indenter 77.05°, therefore, the indenter is selected from the Bosch indenter. The hardness of the C surface of sapphire is 29Gpa, and its hardness value is relatively large. The maximum load is set to 500mN, the incision rate is 1μm / s, and the incision distance is 50μm. The mechanical constants of sapphire are respectively: hardness H=29Gpa, elastic modulus E=430Gpa, Poisson’s ratio ν=0.25, Bosch indenter equivalent half-cone angle α=35.16°; into formula (4), the plastic deformation stage is obtained The relationship cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com