Monitoring device for temperature rise and vibration of motor and realizing method thereof

A technology of vibration monitoring and realization method, which is applied in the directions of measuring devices, motor generator testing, measuring electricity, etc., can solve problems such as failure of motor alarm, unreliable judgment information, increased vibration, etc., to overcome incomplete monitoring information, power supply Way safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

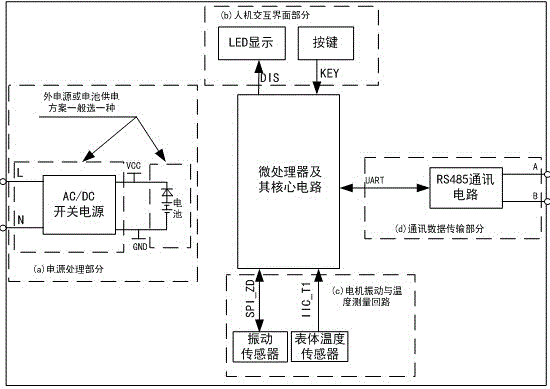

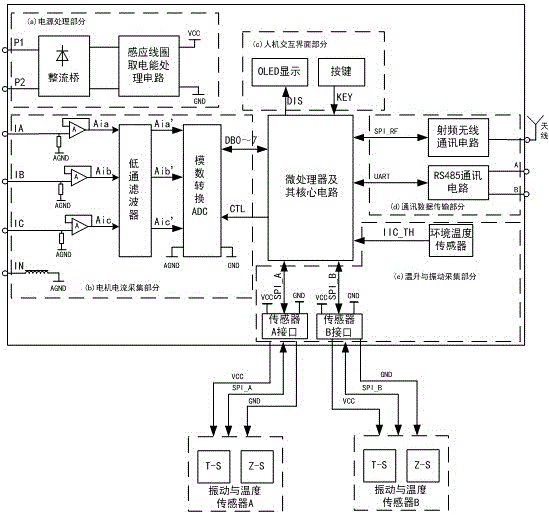

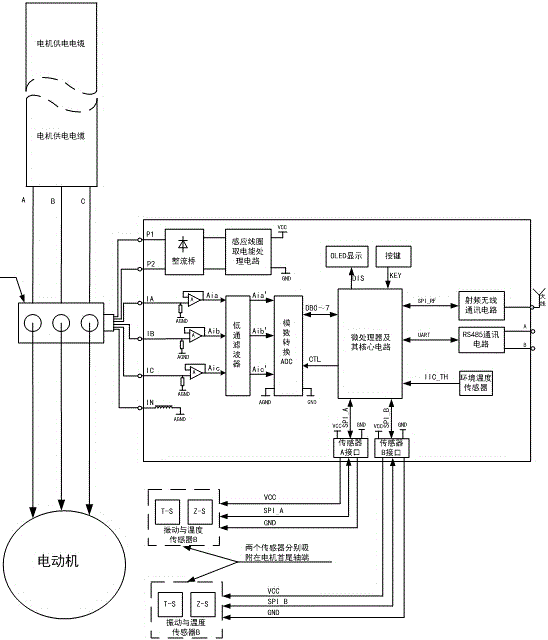

[0049] Such as figure 2 , 3As shown, this embodiment provides a motor temperature rise and vibration monitoring device, which mainly includes five parts: (a) power processing part; (b) motor current acquisition part; (c) human-computer interaction part; (d) Communication data transmission part; (e) temperature rise and vibration collection part. Among them, the power processing part is responsible for processing the power supply and supplying power to the device. The motor current acquisition part is responsible for collecting and transforming the voltage signal converted from the current obtained by the current transformer. The human-computer interaction part is used to realize human-computer interaction. The lift and vibration collection part is responsible for collecting motor vibration and temperature data information, and the communication data transmission part is responsible for uploading the monitoring status and data of the motor to the host computer and detection s...

Embodiment 2

[0062] On the basis of Embodiment 1, the difference between the motor temperature rise and vibration monitoring device provided in this embodiment compared with the prior art lies in:

[0063] power handling

[0064] The existing monitoring device point power supply methods include: one is a battery power supply method, and the other is a mains AC220V input method. Battery power supply generally uses alkaline batteries to power the device. When the battery power is low, the battery needs to be replaced. Mains input adopts switching power supply (AC / DC) to supply power to the device. The battery power supply needs to replace the battery when the battery energy is insufficient, while the mains power supply has the defects of electric leakage and electric shock hazard. The motor temperature rise and vibration monitoring device provided in this embodiment adopts electromagnetic isolation type induction energy harvesting for power supply, and is realized through a power processin...

Embodiment 3

[0066] On the basis of Embodiment 1, the difference between the motor temperature rise and vibration monitoring device provided in this embodiment compared with the prior art lies in:

[0067] Human-Computer Interaction

[0068] In the prior art, the human-computer interaction part is displayed in the form of a digital tube (LED), generally in the form of letters or segment codes, which can only display general letters and numbers, but cannot display complex information such as Chinese characters. At the same time, the existing man-machine Interaction modules cannot be used in low temperature conditions. The human-computer interaction module provided in this embodiment is mainly composed of buttons and an OLED screen. The OLED is a realization screen composed entirely of LED dot matrix, and has the characteristics of long life and wide working temperature. Users can set parameters such as vibration, temperature rise, and overload of the motor through the human-computer intera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com