Louver and air vent having at least one louver

An air exhaust, air outlet technology, used in air handling equipment, household appliances, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

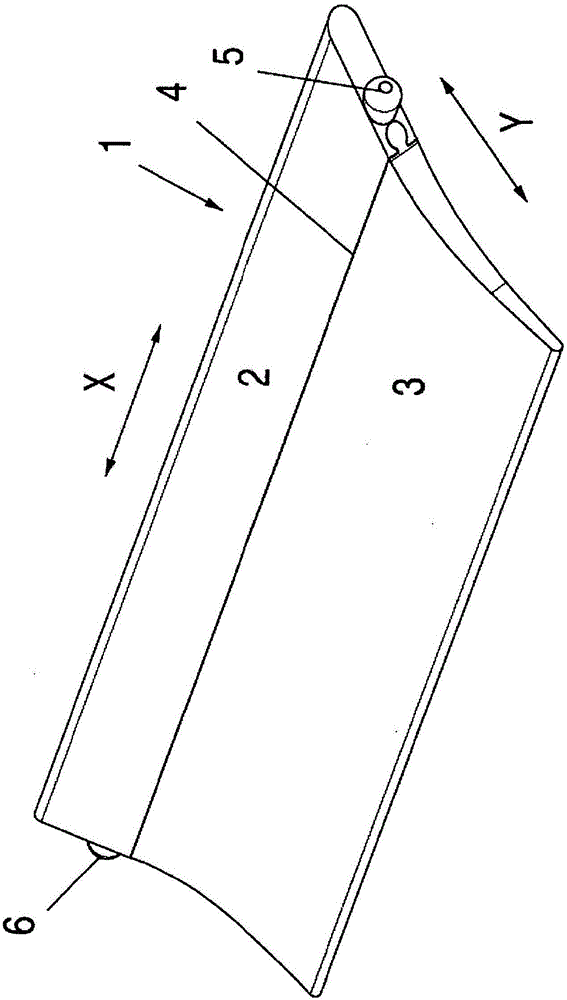

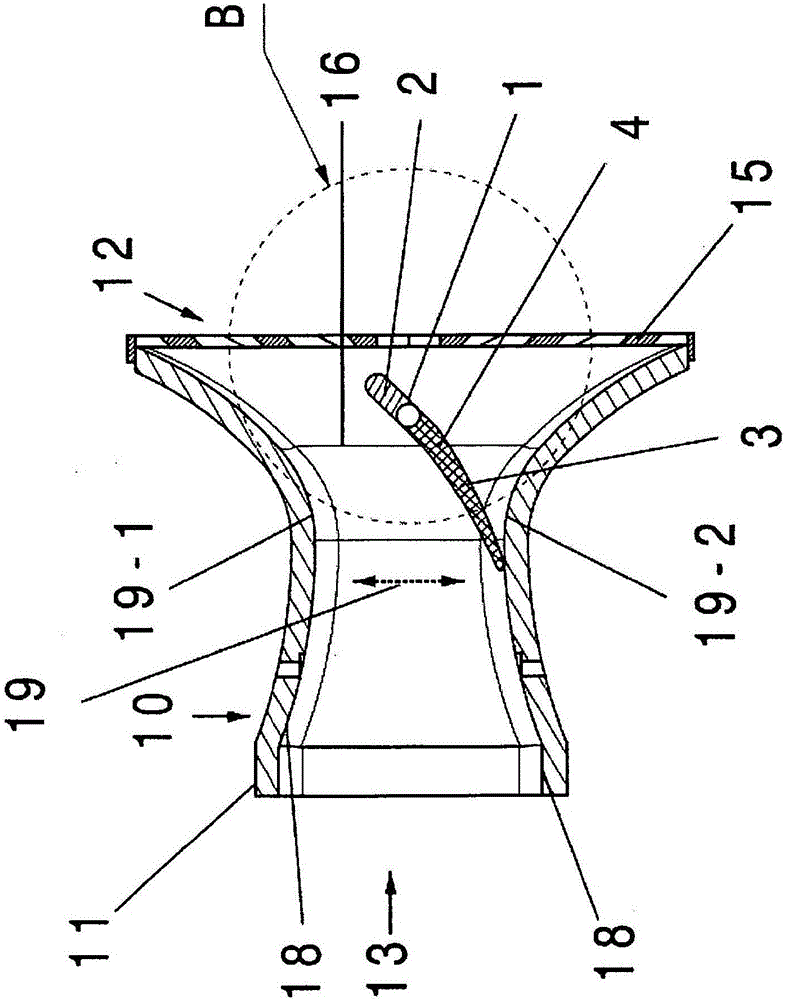

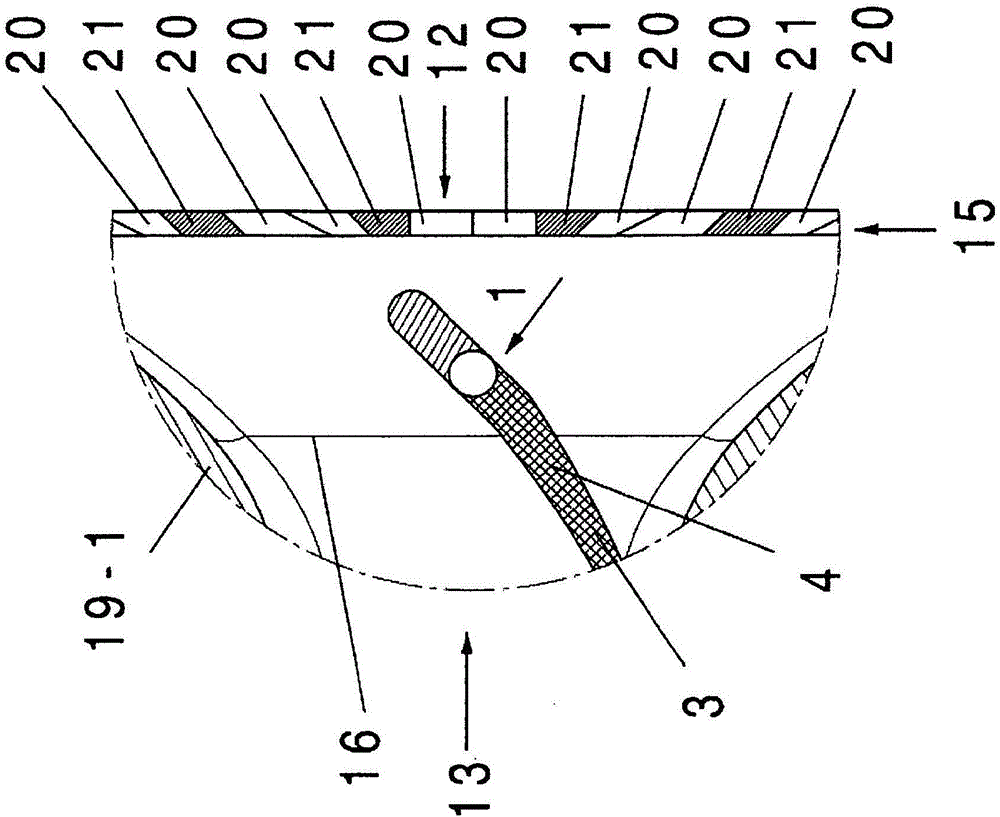

[0045] exist figure 1 An embodiment of a blade 1 according to the invention is shown in . The blade is made of plastic and in its figure 1 is designed for embedding and / or mounting in the air vent of a vehicle, preferably a motor vehicle. The blade 1 is provided with shapings 5 , 6 for connection to other components or for bearing on components or for fixing components. The blade 1 mainly comprises two regions, a front region 2 and a rear region 3 . The front area 2 is made of thermoplastic material with additives added. In an advantageous version of the invention, the front region 2 is made of polyamide or polyaramid incorporating short fibers, wherein the fibers are carbon fibers, wire segments or plastic fibers with a rough surface, glass fibers or wire.

[0046] The blade 1 has a cross-sectional structure which is preferably planar, but also corrugated or angular. Likewise, the blade 1 may have a planar, wavy or distributed angular structure in the direction of e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap