Fuel hose assembly for in-flight fuelling of aircraft

A hose assembly, aerial refueling technology, used in aircraft parts, hoses, pipes/fittings/fittings, etc., which can solve the problem of unlikely safety certification, the IFR system is not suitable for large civil aircraft, and the lateral movement of the hose is large. and other problems, to achieve high fuel pressure and flow rate, high longitudinal stiffness and stability, space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

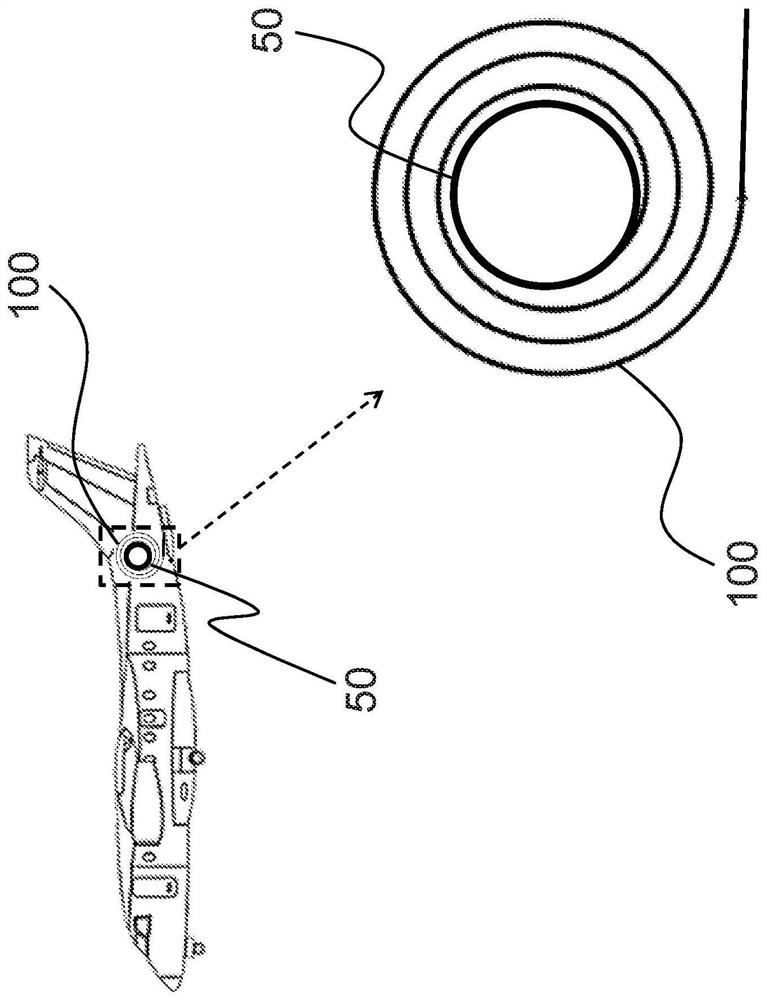

[0040] figure 1 A fuel dispenser is shown comprising a fuel hose assembly 100 coiled on a motorized hose drum unit 50 and provided with a fuel supply carried by the dispenser.

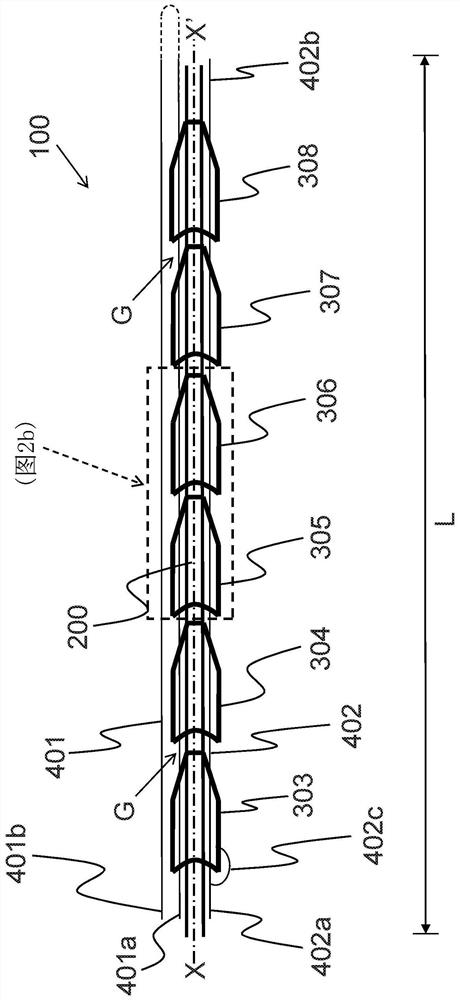

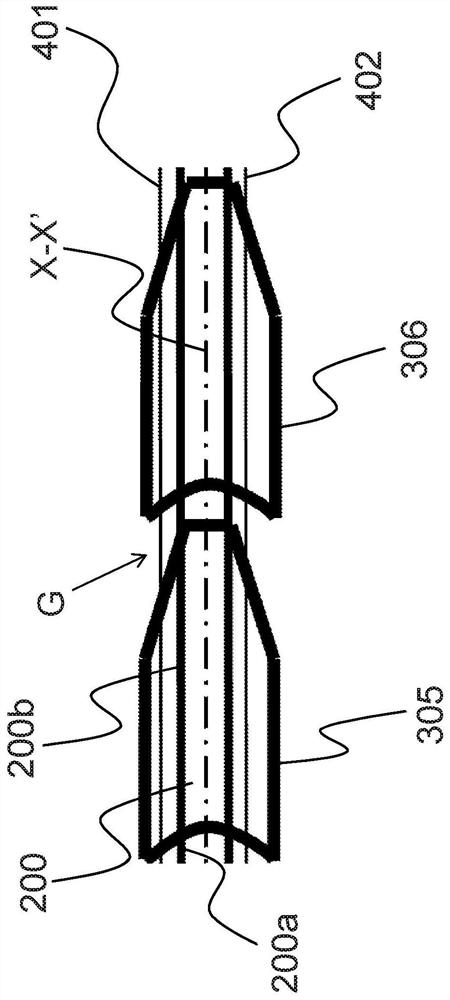

[0041] Figure 2a An exemplary portion of fuel hose assembly 100 is shown having a length L and a longitudinal axis XX′. The fuel hose assembly 100 includes an elongated tubular core 200, a plurality of rigid segments 301-311, and first and second control strands 401, 402 and auxiliary strands (in Figure 2a Only one auxiliary rope 402c) is shown in . Rigid segments 301-311 are separated by gap G (spaced apart). It should be understood that in Figure 2a Only some of the rigid segments 303 - 308 of the fuel hose assembly 100 are visible in FIG. 1 because only a portion of the fuel hose assembly 100 is shown. For ease of understanding the following description, Figure 2b show Figure 2a An enlarged detail of a portion of the fuel hose assembly 100 .

[0042] The tubular core 200 includes an inn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap