Cyperus esculentus harvester

A harvester and oil bean technology, applied in the field of agricultural machinery, can solve the problems of high labor intensity of manual harvesting, incomplete fruit processing, unsatisfactory screening effect, etc., and achieve the effects of reasonable structure, cost reduction, and labor intensity reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

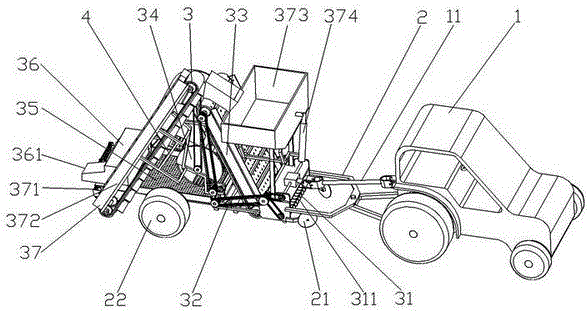

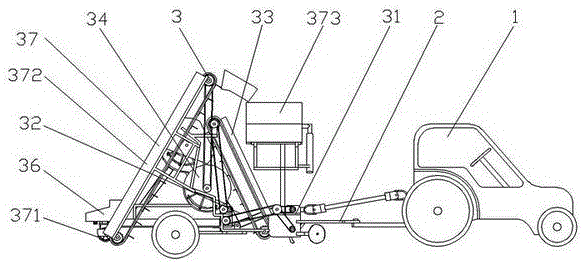

[0025] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown, the present invention is made up of trolley 1, trailer 2 and harvesting device 3, and trailer 2 is arranged on the rear end of trolley 1, and harvesting device 3 is fixedly arranged on trailer 2;

[0026] The rear end of the carriage 1 has a transmission shaft 11;

[0027] The front end of the trailer 2 has a groove 21, and the rear end has a running wheel 22;

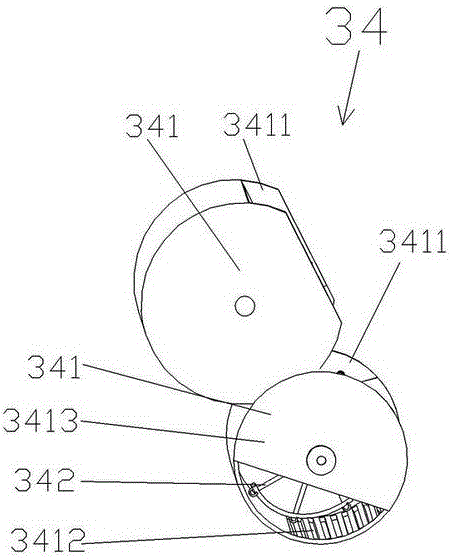

[0028] The harvesting device 3 comprises a bean digging device 31, a first transport device 33, several cylindrical separation devices 34, a screen device 35, a suction fan device 36 and a feeding device 37, and the bean digging device 31 is fixedly arranged on the front end of the trailer 2. A transmission device 33 is fixedly arranged on the upper end of the bean-digging device 31, a cylindrical separation device 34 is fixedly arranged under the first transmission device 33, a screen device 35 is fixedly arranged on the trailer 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com