a mixer

A mixing machine and mixing technology, which is applied in the field of mixing machines for powder mixing, can solve the problems of affecting the uniformity of mixing, affecting the yield of final products, and easy bonding into agglomerates, so as to ensure uniformity and ensure mixing The effect of uniform material and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

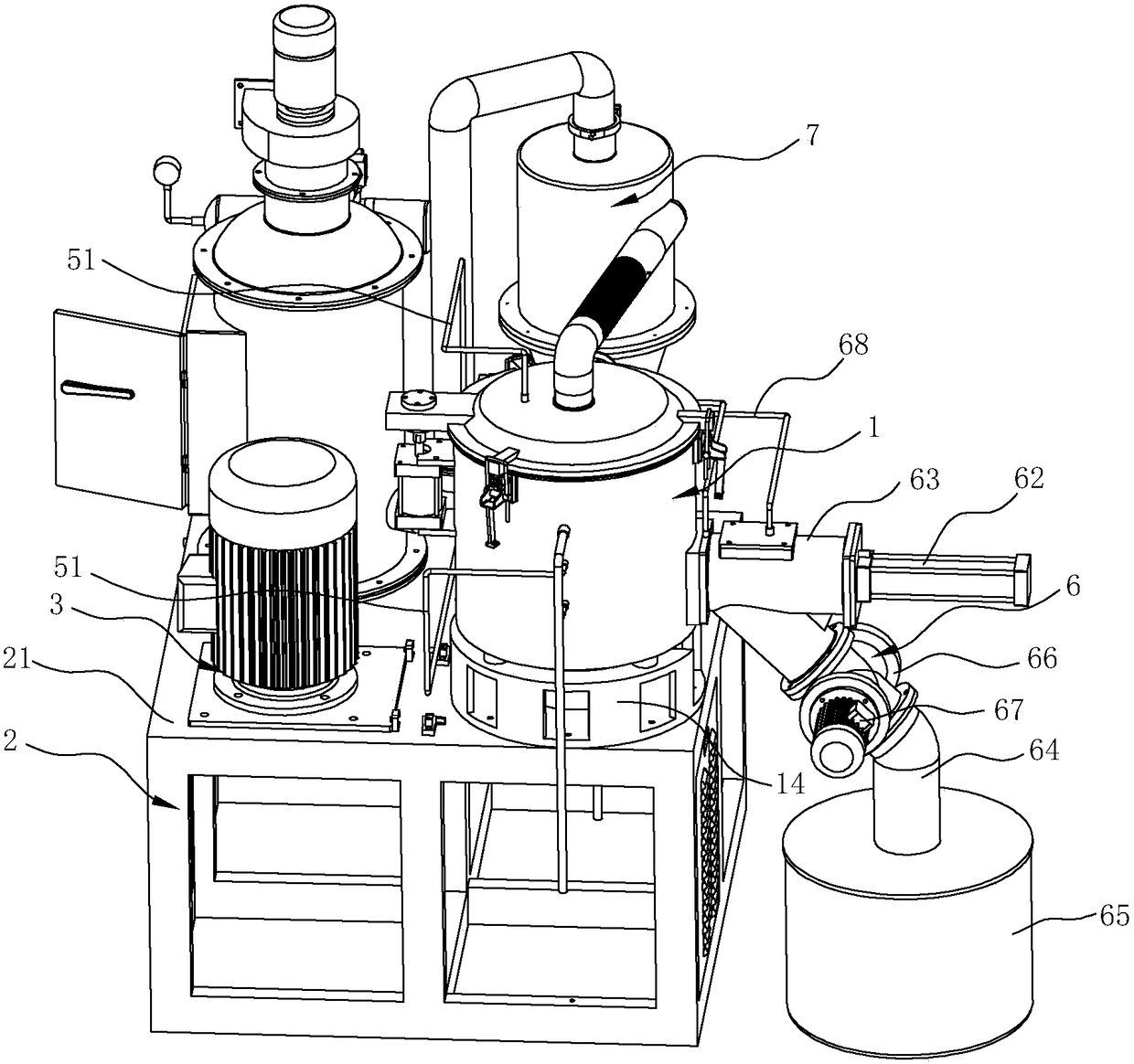

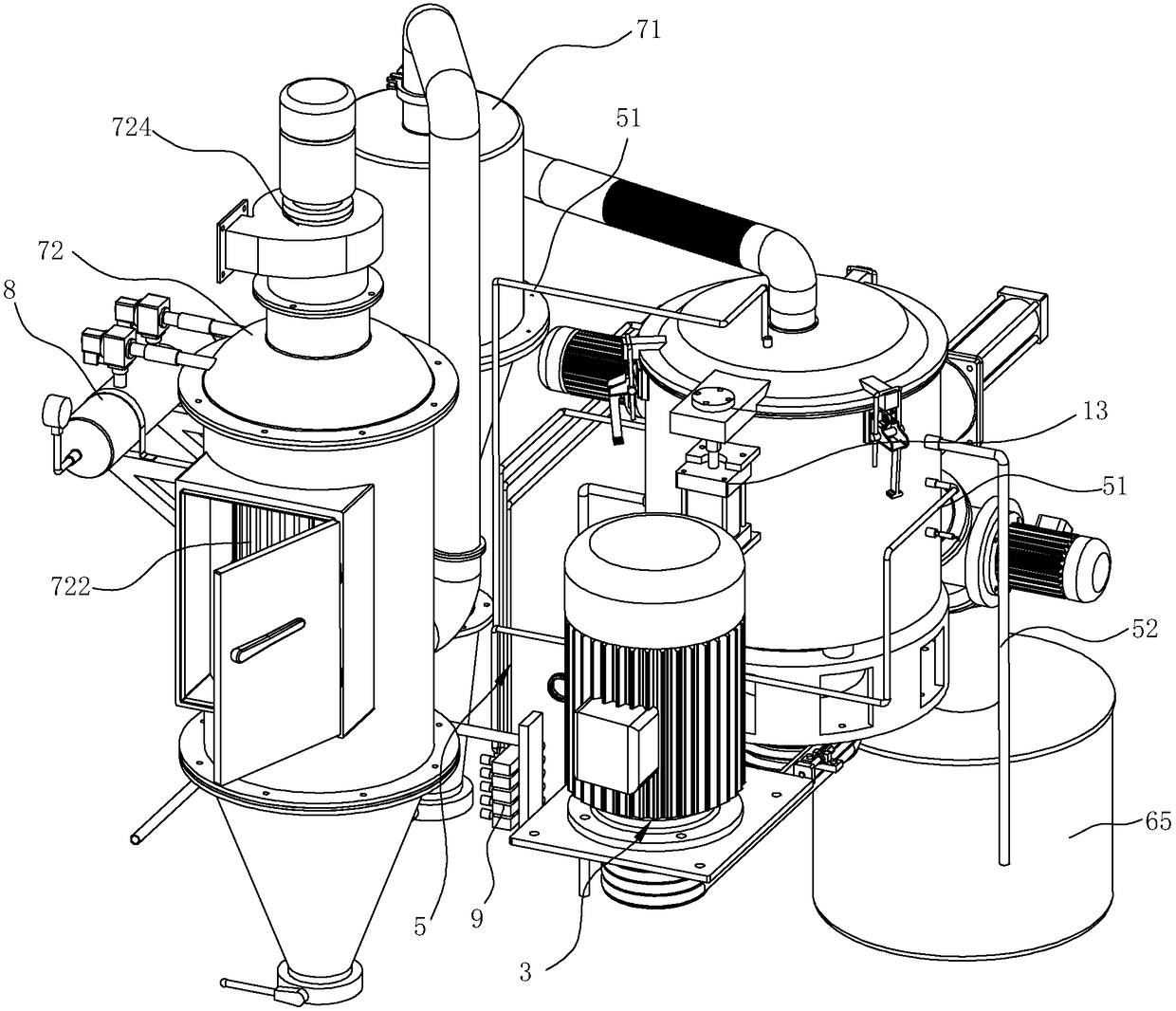

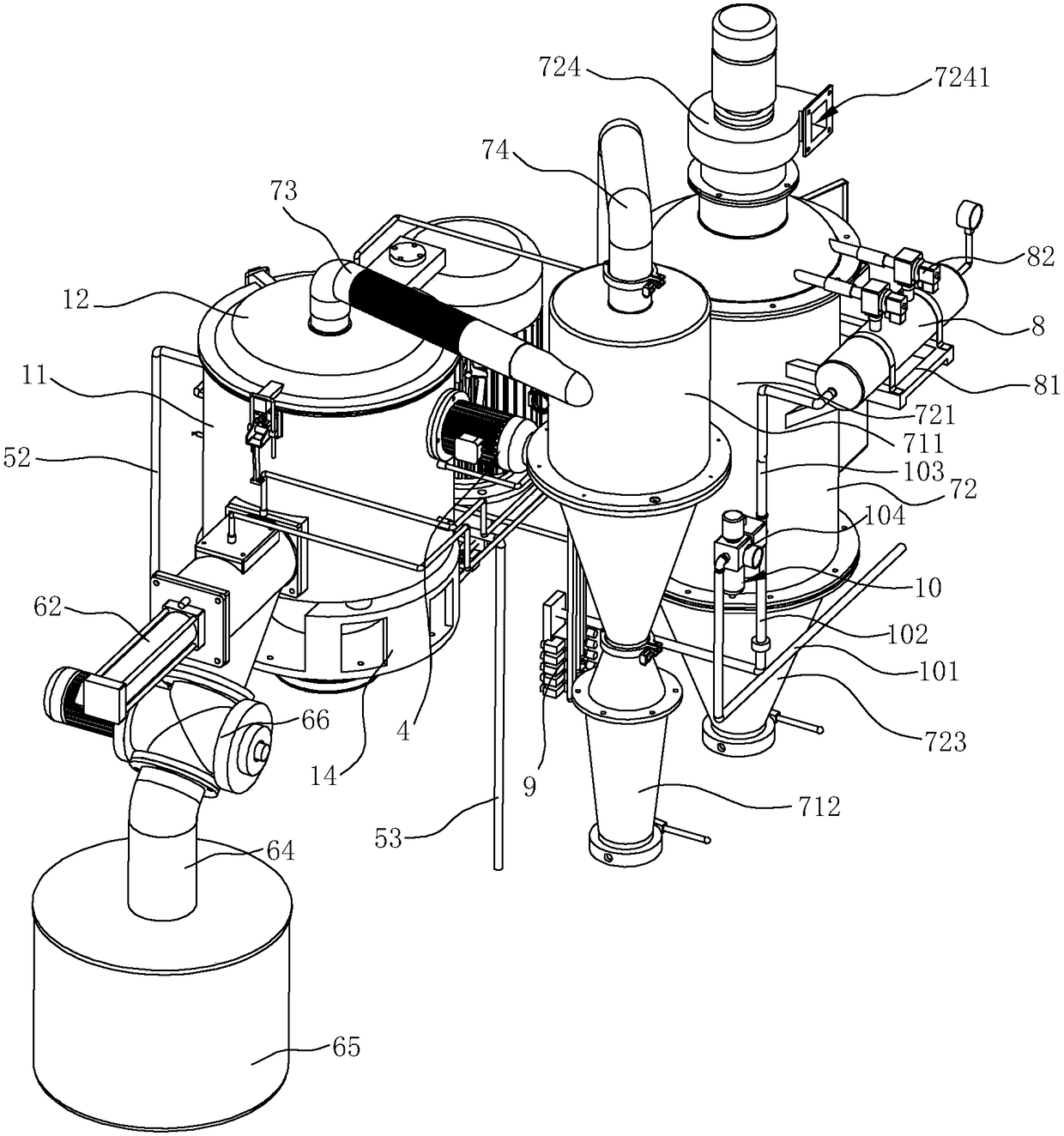

[0023] see Figure 1 ~ Figure 3 , a mixer, used for mixing powder, especially for stirring and mixing polytetrafluoroethylene powder. It includes a mixing mechanism 1 and is arranged on a frame 2. The mixer also includes a main driving device 3 , an auxiliary driving device 4 , a cooling mechanism 5 , a feeding mechanism 6 , a filtering mechanism 7 and an air storage tank 8 .

[0024] see Figure 4 The mixing mechanism 1 includes a barrel body 11 and a cover body 12 for closing the barrel body 11. The barrel body 11 is used to contain polytetrafluoroethylene powder, and the barrel body 11 is used for stirring and mixing. The lid body 12 is hinged on the barrel body 11 and can be connected with the lid body driving mechanism 13. The lid body driving mechanism 13 can preferably be an air cylinder, so that the lid body 12 can be opened and clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com