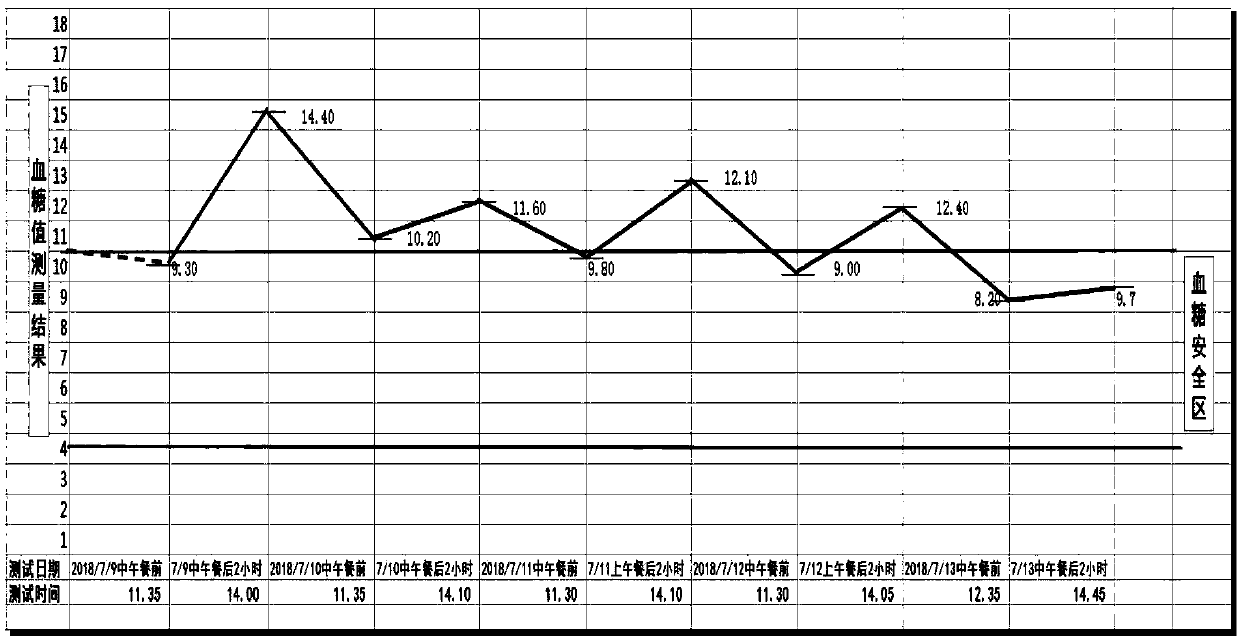

Functional staple food grain for preventing postprandial hyperglycemia of diabetes patient and preparation process method

A preparation process and functional technology, applied in the field of biotechnology, can solve serious problems and achieve the effects of preventing hyperglycemia, reducing total content, and lowering cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

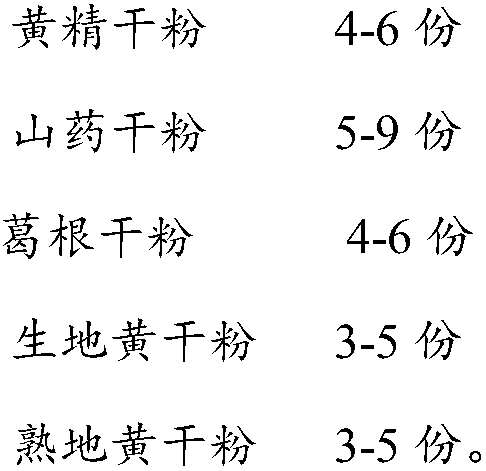

Method used

Image

Examples

Embodiment 1

[0071] The preparation technology of each component dry fine powder such as A, corn oat

[0072] 1-1 Corn (high straight-chain corn is selected for the variety, and the resistant starch content is about 60% in the biochemical state), the ash is removed by the dry blower wind blowing gravity screening method, the metal foreign matter is removed by the magnetic method, and the corn is peeled to remove the germ in the thresher , Obtain 55kg of corn flour that removes germ for subsequent use.

[0073] 1-2. Oats are dried with a blower and blown by gravity to remove ash, magnetically removed metal foreign matter, peeled and cored in a threshing machine, separated from oat skin and solids, and keep 20kg of oat bran for later use.

[0074] 1-3. Blend according to the ratio of 55kg of corn flour and 20kg of oat bran, and grind it into 75kg of ≥60-80 mesh fine powder in a grinder, and set aside.

[0075] B. The preparation process of gelatinization process

[0076] 2-1. Premix the ingr...

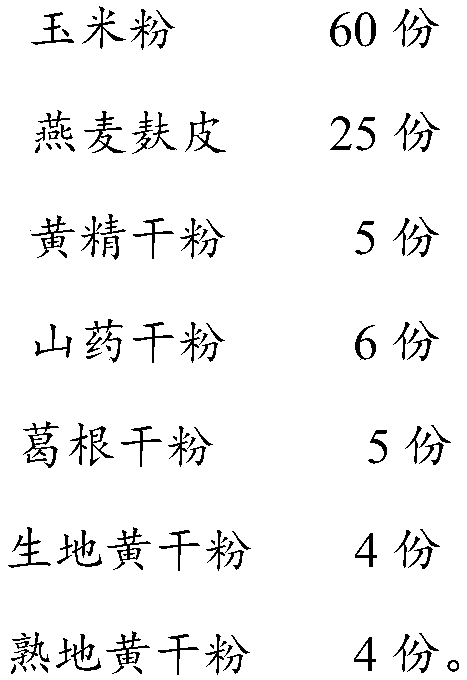

Embodiment 2

[0091] The preparation technology of each component dry fine powder such as A, corn oat

[0092] 1-1 Corn (high straight-chain corn is selected for the variety, and the resistant starch content is about 60% in the biochemical state), the ash is removed by the dry blower wind blowing gravity screening method, the metal foreign matter is removed by the magnetic method, and the corn is peeled to remove the germ in the thresher , Obtain 60kg of corn flour that removes the germ for subsequent use.

[0093] 1-2. Oats are dried with a blower and blown by gravity to remove ash, magnetically removed metal foreign matter, peeled and cored in a threshing machine, separated from oat skin and solids, and keep 25kg of oat bran for later use.

[0094] 1-3. Blend according to the ratio of 60kg of corn flour and 25kg of oat bran, and grind it into 85kg of 60-80 mesh fine powder in a grinder, and set aside.

[0095] 1-4. Polygonatum dry powder, Rhizoma Polygonatum, soaked in water and stirred,...

Embodiment 3

[0115] The preparation technology of each component dry fine powder such as A, corn oat

[0116] 1-1 Corn (high straight-chain corn is selected for the variety, and the resistant starch content is about 60% in the biochemical state), the ash is removed by the dry blower wind blowing gravity screening method, the metal foreign matter is removed by the magnetic method, and the corn is peeled to remove the germ in the thresher , Obtain 65kg of corn flour that removes germ for subsequent use.

[0117] 1-2. Oats are dried with a blower and blown by gravity to remove ash, magnetically removed metal foreign matter, peeled and cored in a threshing machine, separated from oat skin and solids, and keep 30kg of oat bran for later use.

[0118] 1-3. Blend according to the ratio of 65kg of corn flour and 30kg of oat bran, and grind it into 95kg of ≥60-80 mesh fine powder in a grinder, and set aside.

[0119] 1-4. Rhizoma Polygonatum dry powder, the Rhizoma Rhizoma Polygonatum dry powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com