Integrated display backboard drawing and bending die

A bending die and display technology, applied in the field of sheet metal stamping processing, can solve the problems of discontinuous production, high equipment cost, and low work efficiency, and achieve the effect of reducing the number of molds, reducing production costs, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

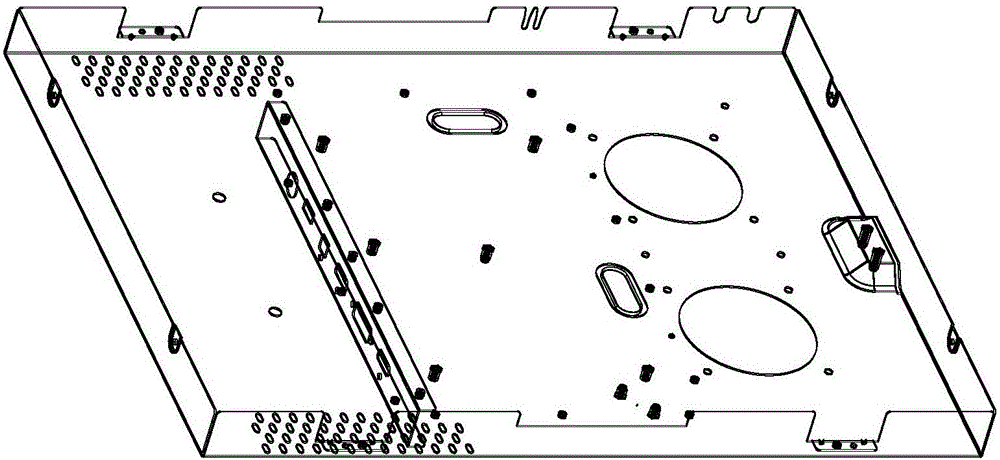

Image

Examples

Embodiment Construction

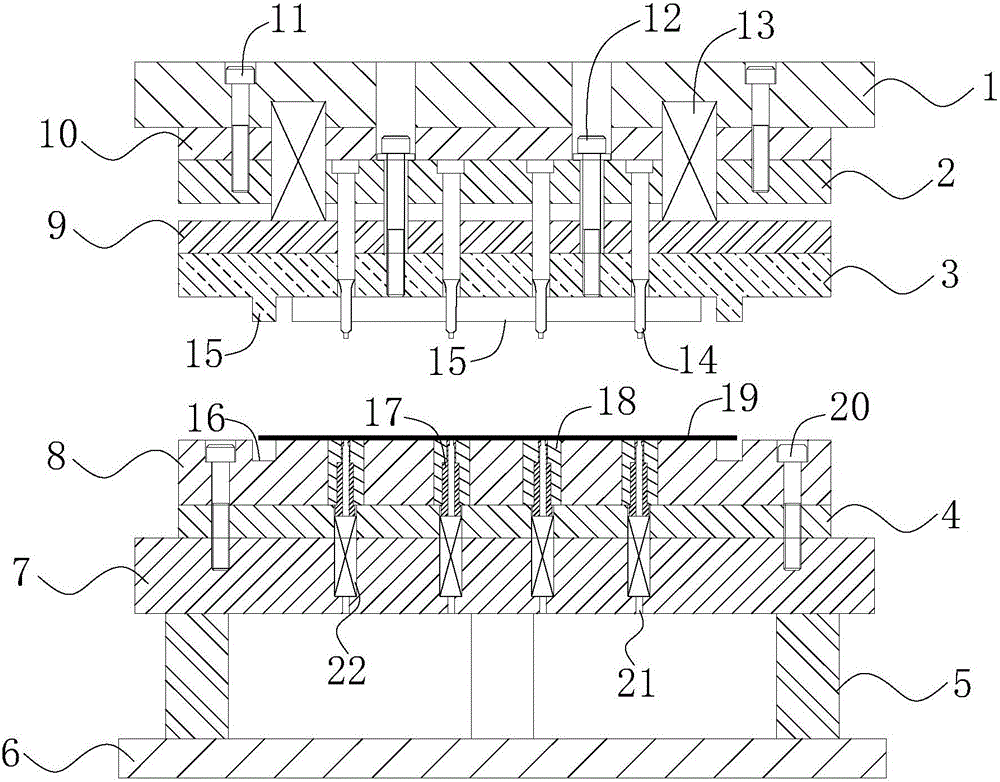

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, the drawings only show some but not all structures related to the present invention, and the drawings are only for the purpose of illustration, and are not drawn according to the original scale.

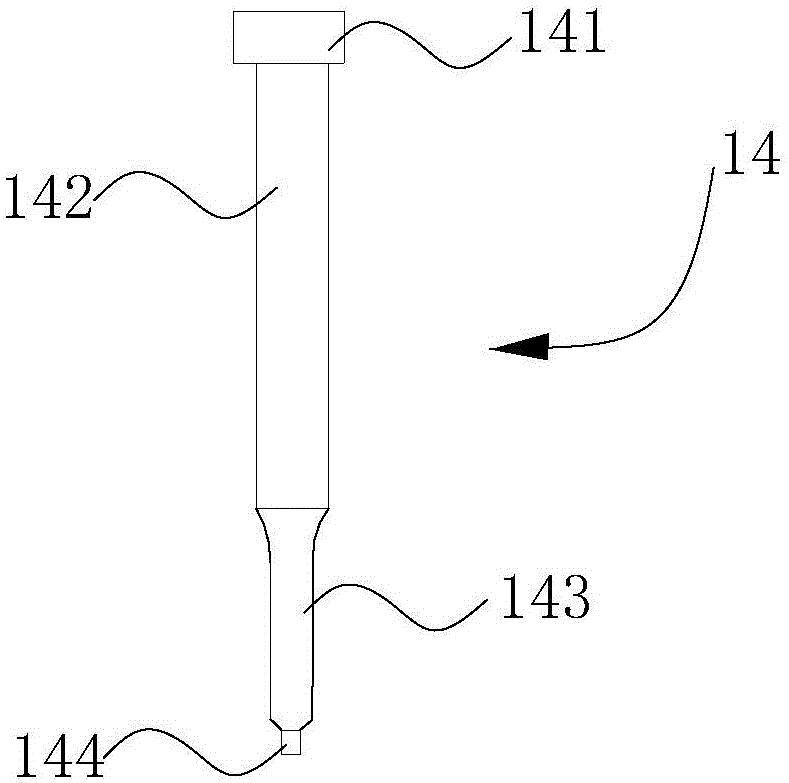

[0028] Such as Figure 2-Figure 5 As shown, this embodiment provides a preferred all-in-one display backplane drawing tooth bending mold, the mold includes an upper mold and a lower mold, wherein the upper mold includes an upper mold base 1, an upper clamping plate connected sequentially from top to bottom 2 and the upper template 3, a first elastic member 13 is connected between the upper mold base 1 and the upper mold base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com